Site Preparation and Installation

Liebert

®

Mini-Mate2

™

18

Connections for Ducted Systems

Use flexible duct work or non-flammable cloth collars to attach duct work to the unit and to help

control the transmission of vibrations to building structures. Insulation of duct work is vital to

prevent condensation during the cooling cycle. The use of a vapor barrier is required to prevent

absorption of moisture from the surrounding air into the insulation.

If the return air duct is short or if noise is likely to be a problem, sound-absorbing insulation should

be used inside the duct. Duct work should be fabricated and installed in accordance with national and

local codes.

Additional components such as a free-cooling coil, hot water reheat coil or high efficiency filters will

reduce available static pressure.

5.4.3 Piping Connections and Coolant Requirements

Drain Line

NOTICE

Risk of water backing up in the evaporator coil drain line and overflowing the drain pan. Can

cause building and equipment damage.

Do not install an external trap in the drain line. This line already has a factory-installed trap

inside the cabinet.

This line may contain boiling water. Use copper or other suitable material for the drain line.

A 3/4 in. (19.1 mm) NPT-female connection is provided for the evaporator coil condensate drain. This

line also drains the humidifier, if applicable. The drain line must be located so it will not be exposed to

freezing temperatures. The drain should be the full size of the drain connection.

The evaporator drain pan includes a float switch to prevent unit operation if drain becomes blocked.

The optional condensate pump kit is required when the evaporator is installed below the level of the

gravity-fed drain line.

Humidifier Water Supply Line

Units supplied with the optional humidifier package have a 1/4 in. (6.4 mm) copper compression

fitting connection for water inlet. Supply pressure range is 10 psig to 150 psig. Required flow rate is

1 gpm (3.8 lpm). A shut-off valve should be installed in this line to isolate the humidifier for

maintenance.

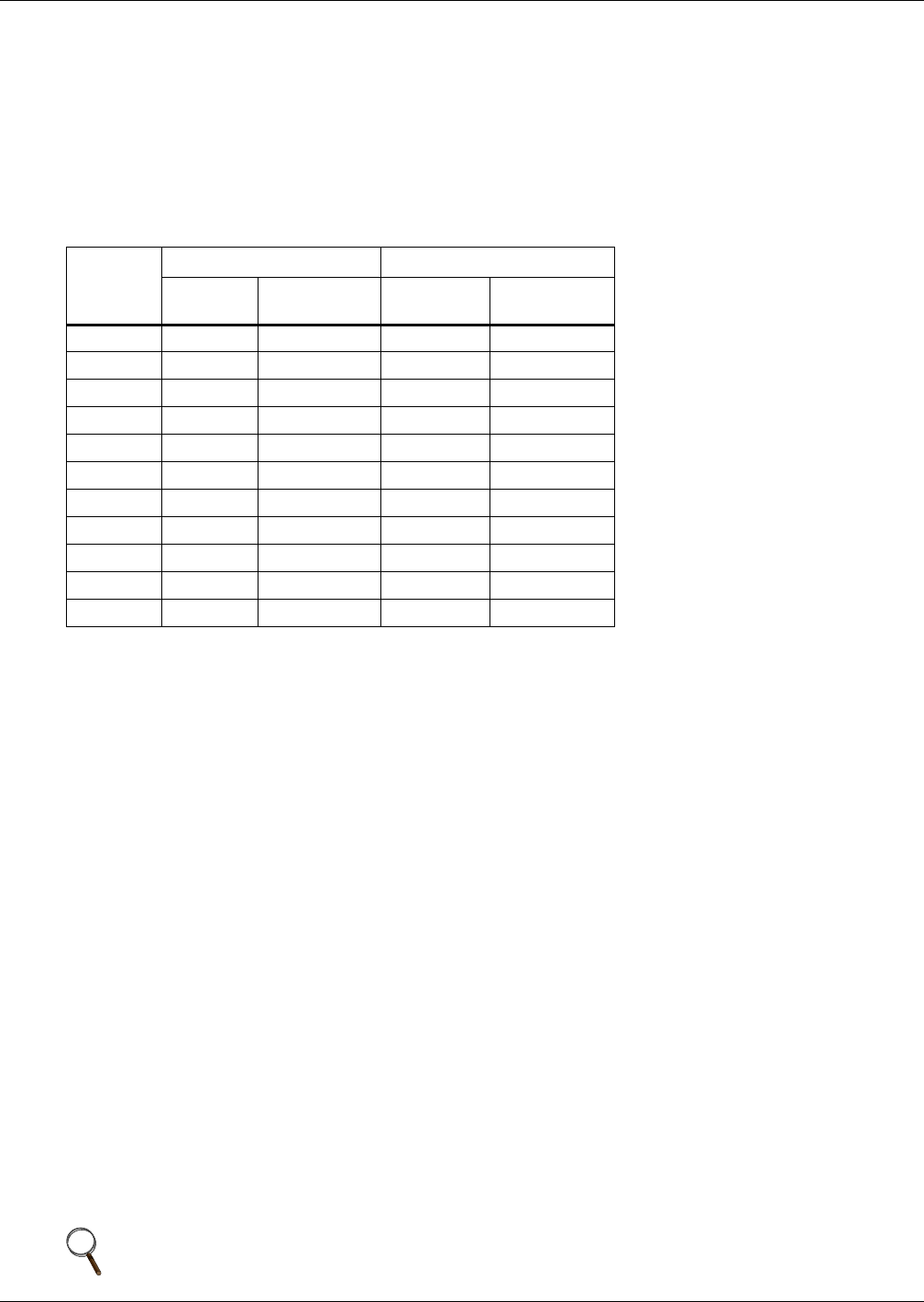

Table 7 Evaporator external static pressure

Turns

Open

1.5 hp Motor (60hz) 2.0 hp Motor (60hz)

Blower

rpm

External

Static, in.

Blower

rpm

External

Static, in.

1n/a n/a 1329 n/a

1.5 n/a n/a 1296 n/a

2 1037 0.9 1264 n/a

2.5 1005 0.7 1231 1.5

3 972 0.6 1199 1.4

3.5 940 0.5 1164 1.3

4 907 0.4 1134 1.2

4.5 875 0.3 1102 1.1

5 843 0.2 1069 1.0

5.5 810 0.1 1037 0.9

6 778 0.0 1005 0.7

NOTE

Do NOT route humidifier supply line in front of filter box access panel.