Site Preparation and Installation

Liebert

®

Mini-Mate2

™

14

5.0 SITE PREPARATION AND INSTALLATION

5.1 Installation Considerations

The evaporator unit is usually mounted above the suspended ceiling in the space to be conditioned.

Ducted systems may be located in a different room. Refer to Figure 8 and Figure 9 for possible

configurations. The condensing unit may be:

• Indoor Air-Cooled Centrifugal Fan Condensing Unit mounted remotely or close coupled to the

evaporator in the ceiling space.

• Outdoor Air-Cooled Propeller Fan Condensing Unit.

• Water/Glycol Cooled Condensing Unit, mounted remotely or close coupled to the evaporator.

5.1.1 Room Preparation

The room should be well insulated and must have a sealed vapor barrier. The vapor barrier in the

ceiling and walls can be a polyethylene film. Paint on concrete walls and floors should contain either

rubber or plastic.

Outside or fresh air should be kept to a minimum when tight temperature and humidity control is

required. Outside air adds to the cooling, heating, dehumidifying and humidifying loads of the site.

Doors should be properly sealed to minimize leaks and should not contain ventilation grilles.

NOTE

Before installing unit, determine whether any building alterations are required to run piping,

wiring and duct work. Carefully follow all unit dimensional drawings and refer to the

submittal engineering dimensional drawings of individual units for proper clearances.

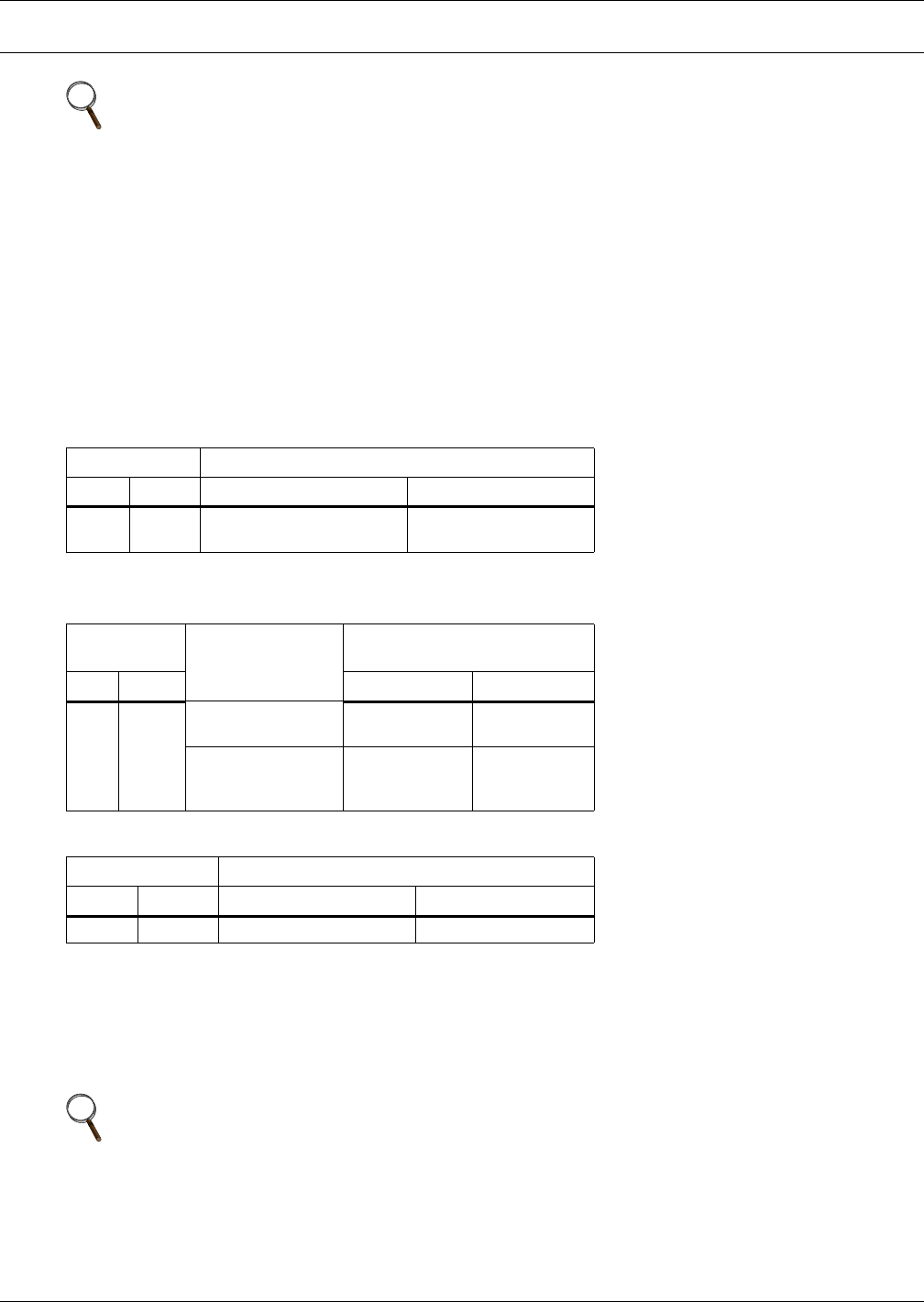

Table 3 Application limits, evaporator and chilled water units*

Input Voltage Range of Return Air Conditions to Unit

Min Max Dry Bulb Temperature Relative Humidity

-5% +10% 65°F to 85°F

(18

°C to 29°C)

20% to 80%

*Unit will operate at these conditions but will not control to these extremes.

Table 4 Application limits, indoor and outdoor air-cooled condensing units

Input

Voltage

Condensing

Units

Entering Dry Bulb Air

Temperature

Min Max Min Max

-5% +10% Outdoor Prop Fan

Condensing Unit

-30°F (-34°C) 120°F (49°C)

Indoor Air-Cooled

Centrifugal

Condensing Unit

-20°F (-29°C) 115°F (46°C)

Table 5 Application limits, indoor water/glycol cooled condensing units

Input Voltage Entering Fluid Temperature

Min Max Min Max

-5% +10% 65°F (18.3°C) * 115°F (46°C)

*Operation below 65°F (18°C) may result in reduced valve life and fluid noise.

NOTE

The single most important requirement for maintaining environmental control in the

conditioned room is the vapor barrier.