12

V Knockdown Boiler Assembly Instructions

10

A. Prior To Assembly

1) Thoroughly inspect the cast iron heat exchanger sections for any shipping damage, i.e. cracks in the castings, broken lugs

or punctures due to mishandling.

2) Do not use a damaged heat exchanger section. Replace it with an undamaged heat exchanger section.

3) Keep the base in the shipping carton until it is time to perform the assembly. This keeps foreign material from contami-

nating the burners or creating other hazards. Do not use the base assembly if there are any signs of visible damage.

4) Review all of the installation requirements in this installation manual.

5) Verify that all needed components are on hand. A complete list of all sections and cartons that should be on hand,

along with their contents, can be found in the Parts Section. A summary of the cartons and their contents is shown

below. All boilers except the 32-475 use multiple base modules and therefore require multiple Base Cartons and

Intermediate Cartons. All boilers larger than the 32-855 require multiple Section Joiner Cartons. Some parts, such as

jacket screws and jacket mounting brackets are packed in both the Base Carton and the Base Side Panel Carton.

B. Base Assembly

1) Each base module is tested and shipped assembled.

a. All boilers are assembled using base modules with inputs of 285, 380 and 475 MBH

b. The model 475 boiler requires only a single base module. All other boiler combinations require multiple

base module subassemblies. See Figure 2 for the proper order of assembly.

c. Join Base Sub-assemblies together. Use (4) 3/8”-16 x 3/4” screws, nuts and washers to attach subassemblies. (See

Figure 4)

d. Assemble the base in the location where the boiler is to be installed. Refer to Sections III and IV in this

manual for additional information on placement.

e. Once the base modules are assembled, install the base end panels. These base end panels must be installed

prior to assembling the sections.

f. The base must be level in both directions and supported under all feet. Shim and grout under base if

necessary.

g. Verify that the front and sides of the base are square.

h. Place cardboard covering over the top of the burners to protect them during the assembly of the boiler

sections.

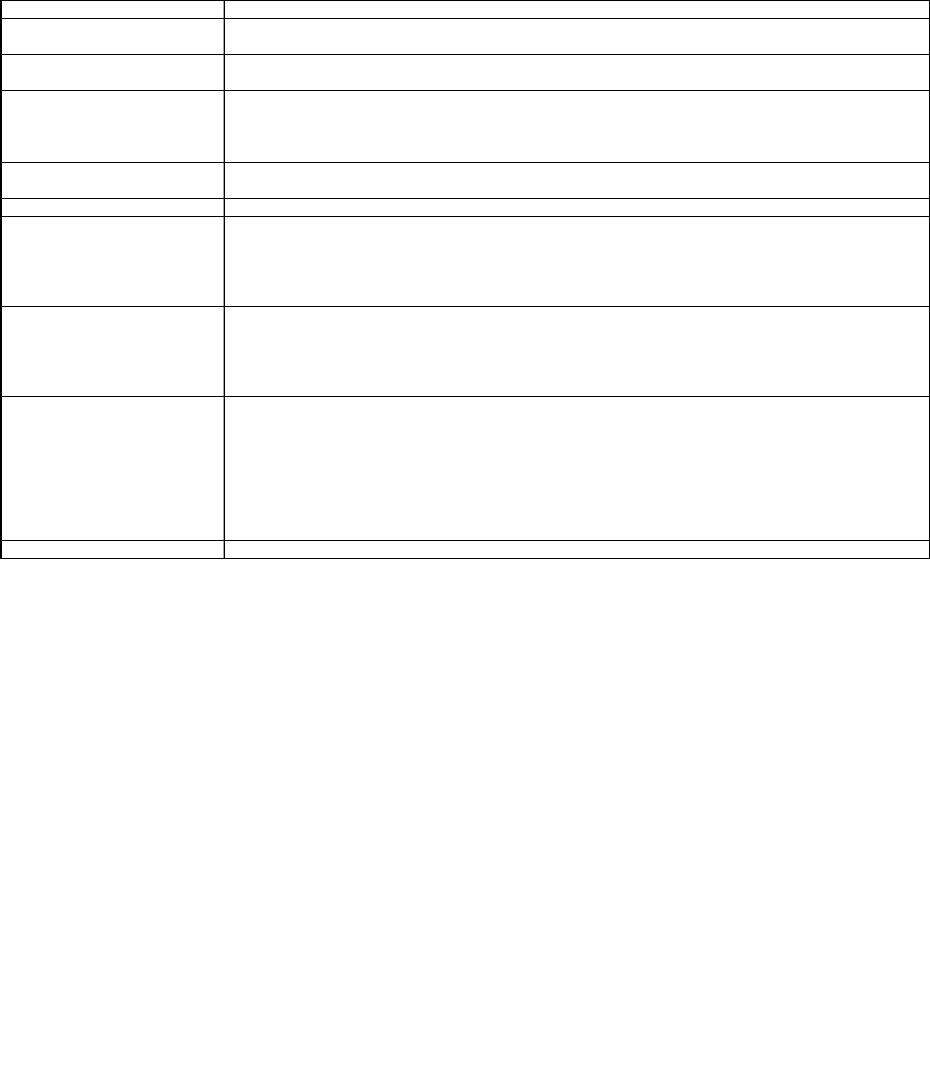

PACKAGE

JACKET SIDE PANEL CARTON

TANKLESS HEATER CARTON

POP SAFETY OR RELIEF VALVE

FITTINGS FOR MOUNTING POP SAFETY OR RELIEF VALVE

WARRANTY

PUSHNIPPLE GAUGE

RATING PLATE

SEALANT FOR SEALING HEAT EXCHANGER TO BASE

TANKLESS COIL OPENING COVER PLATES AND HARDWARE

A

SSORTED FITTINGS

INSTALLATION M ANUAL

USER'S M ANUAL

TANKLESS HEATER (IF USED)

LEFT AND RIGHT SIDE JACKET PANELS

LIMIT CONTROLS

GAUGE

LOW WATER CUT-OFF (CSD-1 BOILERS ONLY)

TANKLESS COIL OPENING COVER PLATES AND HARDWARE

A

SSORTED FITTINGS

LIMIT CONTROLS

GAUGE

LOW WATER CUT-OFFS

PUSHNIPPLE LUBRICANT

SECTION SEALING COMPOUND

BASE SIDE PANELS

BRACKETS AND HARDWARE FOR ATTACHING JACKET AND FLUE COLLECTOR TO SIDES OF BOILER

WATER TRIM CARTON

STEAM TRIM CARTON

BOILER CARTON

SUMMARY OF CONTENTS

BASE MODULE

BRACKETS AND HARDWARE FOR ATTACHING JACKET AND FLUE COLLECTOR

FRONT, TOP, REAR JACKET PANELS

FLUE COLLECTOR

PUSHNIPPLES

TIE ROD HARDWARE

BASE CARTON

INTERMEDIATE CARTON

SECTION JOINER CARTON

BASE SIDE PANEL CARTON