17

Dutchwest Direct Vent / Natural Vent Gas Heater

30001935

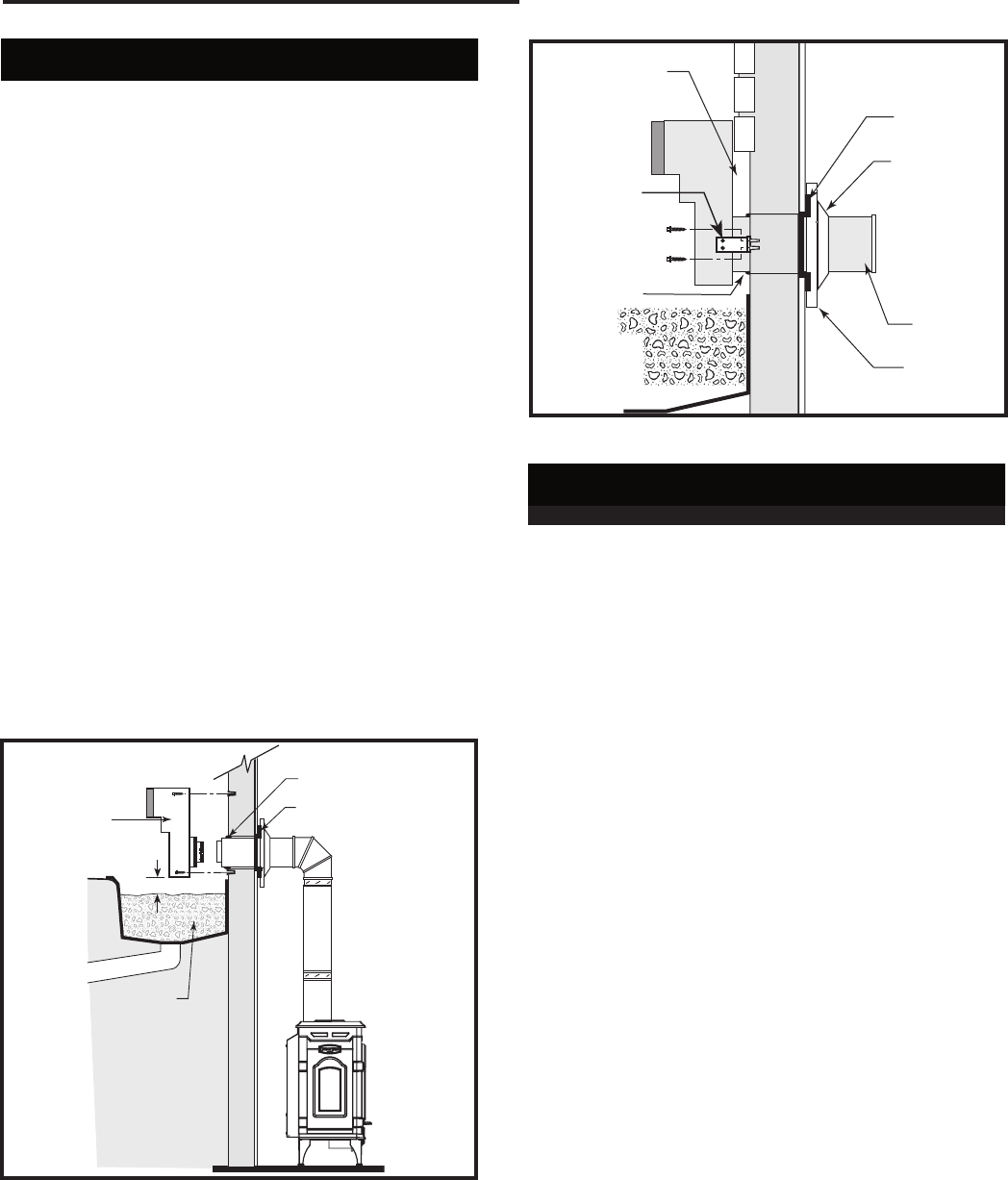

Vent Termination Below Grade

Install Snorkel Kit #7FSDVSKS when it is not possible

to meet the required vent termination clearances of 12”

(305mm) above grade level. The snorkel kit will allow

installation depth of down to 7” (178mm) below grade

level. The seven inches is measured from the center of

the horizontal vent pipe as it penetrates the wall. If the

venting system is installed below grade, a window

well must be installed with adequate and proper

drainage. (Fig. 28)

NOTE: Be sure to maintain side wall clearances and

vent run restrictions. Refer to Figures 3, 4, 7, and 8.

1. Establish the vent hole through the wall.

2. Remove soil to a depth of approximately 16” (406

mm) below the base of the snorkel. Install a window

well (not supplied). Refill the hole with 12” (305mm)

of coarse gravel and maintain a clearance of at least

4” (102 mm) below the snorkel. (Fig. 28)

3. Install the vent system as described on Pages 14-

17.

4. Be sure to make a watertight joint around the vent

pipe joint at the inside and outside wall joints.

5. Apply high temperature sealant around the inner

and outer snorkel collars. Join the pipes and fasten

the snorkel termination to the wall with the screws

provided.

6. Level the soil to maintain a 4” clearance below the

snorkel.

ST218

install snorkel

12/6/99 djt

Waterproof Seal

Around Pipe

Firestop

Window

Well

Drain

Snorkel

Termination

Cap

4” Clearance

Gravel

ST765

Fig. 28 Snorkel kit installation.

ST219

snorkel detail

12/6/99 djt

Recessed Wall

Firestop

Finishing

Collar

7” Pipe

Wall Plate

Sheet Metal

Screws and

Bracket

Wall Screws

and Anchors

Waterproof

Seal Around

Pipe

ST219

Fig. 29 Use extension brackets to mount snorkel against

recessed wall.

If the foundation is recessed, use extension brackets

(not supplied) to fasten the lower portion of the snorkel.

Fasten the brackets to the wall first, and then fasten

to the snorkel with self-tapping #8 x 1/2” sheet metal

screws. Extend the vent pipes out as far as the protrud-

ing wall face. (Fig. 29)

Vertical (Through the Roof)

Vent Assembly

Note that all vertically terminated installations must in-

clude the restrictor plate included with the stove. Refer

to Figure 8, Page 8.

Make certain the vent system conforms to all other

requirements for vertical termination as specified on

Page 8.

This installation will require you to first determine the

roof pitch and use the appropriate vent components.

Refer to Figures 8 and 9 on Pages 8 and 10.

1. Locate the final position of the stove, observing all

clearances for both the vent and the stove.

2. Plumb to the center of the inner (4”) flue collar from

the ceiling above, and mark that location.

3. Cut the opening:

CFM System: 9³⁄₈” x 9³⁄₈” (240mm x 240mm)

DuraVent System: 10” x 10” (254mm x 254mm)

4. Plumb any additional opening through the roof or

other construction that may be needed. In all cases,

the opening must provide a minimum of 1” (25mm)

clearance to the vent pipe.

5. Place the stove in its final position.

6. Install firestop(s) #7DVFS and Attic Insulation Shield

#7DVAIS as needed. (Fig. 30) If there is a room

above ceiling level, a firestop must be installed on

both the bottom and top sides of the ceiling joists.

If an attic is above ceiling level, an attic insulation

shield must be installed.

7. Install the appropriate roof support and flashing,

making certain that the upper flange of the flashing

base is below the shingles. (Fig. 31)