14

Dutchwest Direct Vent / Natural Vent Gas Heater

30001935

Venting System Assembly - Direct Vent

General Information

The Dutchwest is approved for installation only with the

vent components listed on Page 12. Follow the vent

component instructions exactly.

For U.S. installations: The venting system must con-

form with local codes and/or the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

For Canadian installations: The venting system must

conform to the current CSA B149.1 installation code.

Install the Vent Adapter Pipe

(CFM Corporation Vent Components)

1. Install the Restrictor Plate. Consult the ‘Vent Run

Specifications’ on Page 8 to determine whether the

restrictor plate is needed. If so, put the restrictor

plate in place within the inner flue collar as shown in

Figure 16.

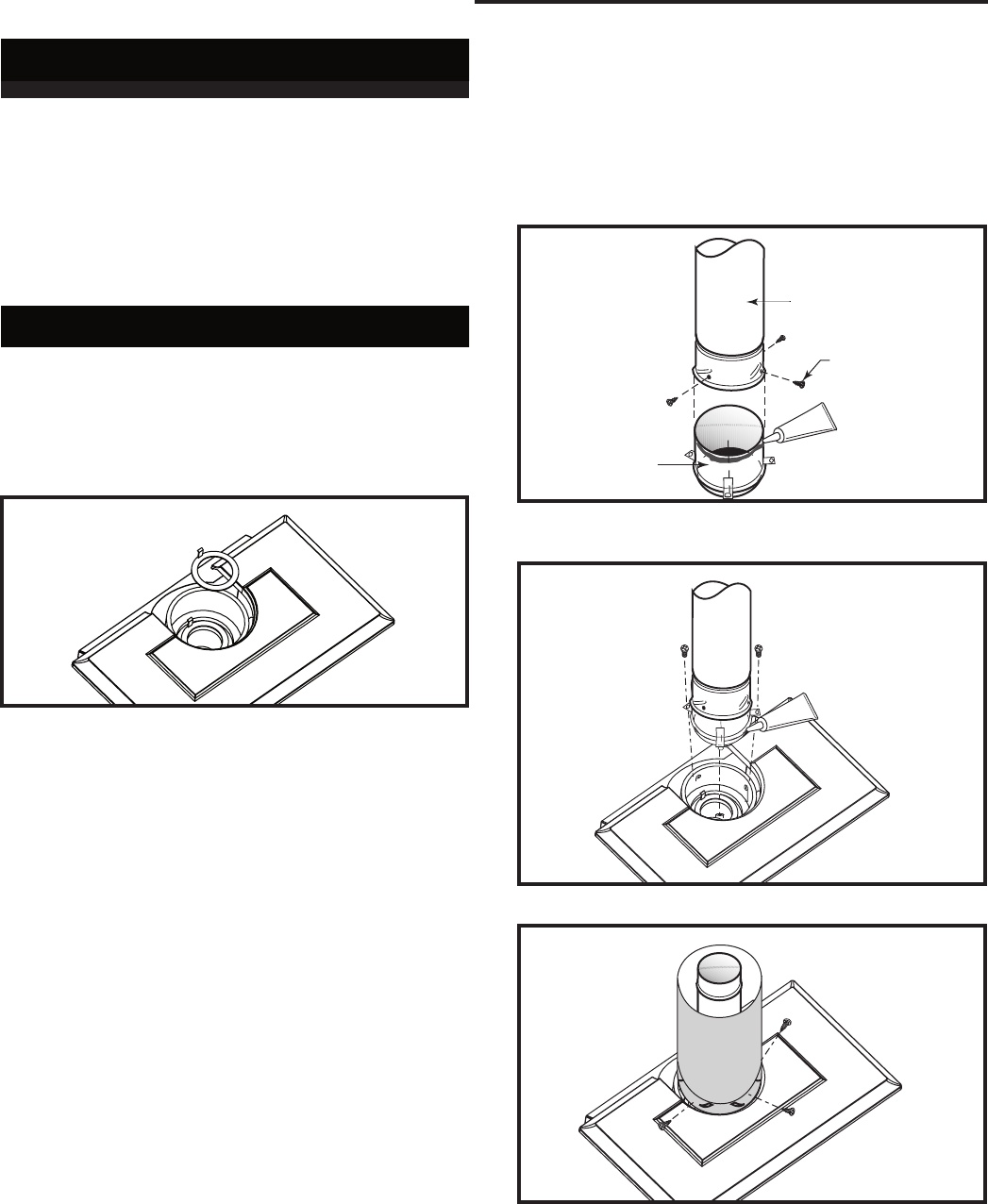

5. Install the Outer Adapter Pipe. Apply a 1/4” bead

of cement around the inside wall of the pipe, about

1” from the end. Insert the pipe over the stove flue

collar, keeping the vertical seam oriented to the back

of the stove. Also, be sure to align holes on the pipe

with the holes on the flue collar of the firebox. Fasten

the pipe to the holes in the flue collar with the #12 x

1/2” sheet metal screws provided. (Fig. 19)

ST759

Dutchwest

restictor plate

5/15/03

ST759

Fig. 16 Install the restrictor plate only if required for the vent-

ing configuration. Refer to Page 8.

2. Attach Inner Starter Pipe, (found in with the logset),

to the next section of inner pipe.

• Run a bead of sealant about 1/2” from the upper

end of the Inner starter pipe and join the two sec-

tions together.

• Drill three pilot holes into the Inner Starter and

secure the assembly with three sheet metal screws.

(Fig. 17)

3. Dry fit the Outer pipe assembly to the stove for the

purpose of determining the center line of the pipe on

the wall.

• Side Wall Terminations: Dry fit the outer elbow

with the vertical outer vent and confirm the centerline

alignment with the wall thimble opening.

Remove the pipes and elbows before continuing with

Step 4.

4. Attach the Inner Vent Assembly to the stove.

• Run a bead of sealant around the bottom end of

the starter pipe and attach the assembly to the stove

using three 1/4-20 x 3/8” Phillips screws provided in

the parts bag. (Fig. 18)

ST211

attach inner pipe

to next section

12/4/99 djt

CEMENT

First Section of

Vent Pipe

#8 x 1/2” Sheet

Metal Screws

4” Inner

Starter Pipe

ST211

Fig. 17 Connect the inner starter with the next section of in-

ner vent pipe.

ST760

attach inner assy

5/15/0 3 djt

CEMENT

ST760

Fig. 18 Attach inner assembly to flue collar.

ST761

attach inner assy

5/15/03 djt

ST761

Fig. 19 Fasten outer pipe with #12 x 1/2” sheet metal screw.