Crankcase Heater — Each compressor has a crankcase heater

to prevent absorption of liquid refrigerant by oil in the crank-

case when the compressor is idle. Since power for the crank-

case heaters is drawn from the unit incoming power, main

unit power must be on for the heaters to be energized.

IMPORTANT: After a prolonged shutdown or serv-

ice job, energize the crankcase heaters for 24 hours

before starting the compressors.

EVAPORATOR FAN MOTOR PROTECTION —A manual

reset, calibrated trip, magnetic circuit breaker protects against

overcurrent. Do not bypass connections or increase the size

of the breaker to correct trouble. Determine the cause and

correct it before resetting the breaker. If the evaporator-fan

motor is replaced with a different horsepower motor, resiz-

ing of the circuit breaker is required. Contact Carrier

Application Engineering.

CONDENSER-FAN MOTOR PROTECTION — Each

condenser-fan motor is internally protected against

overtemperature.

HIGH- AND LOW-PRESSURE SWITCHES — If either

switch trips, or if the compressor overtemperature switch ac-

tivates, that refrigerant circuit will be automatically stopped.

See Compressor Lockout Logic section on this page.

FREEZE PROTECTION THERMOSTAT (FPT) — Freeze

protection thermostats are located on the evaporator coil for

each circuit. One is located at the top and bottom of each

circuit. It detects frost build-up and turns off the compressor,

allowing the coil to clear. Once the frost has melted, the com-

pressor can be reenergized.

Relief Devices — All units have relief devices to pro-

tect against damage from excessive pressures (i.e., fire). These

devices are installed on the suction line, liquid line, and on

the compressor.

Power Circuit — A typical power wiring schematic is

shown in Fig. 56.

Control Circuit, 115-V — This control circuit is pro-

tected against overcurrent by a 5.0 amp circuit breaker (CB3).

Breaker can be reset. If it trips, determine cause of trouble

before resetting. A typical 115-v control wiring schematic is

shown in Fig. 57 and 58.

Control Circuit, 24-V — This control circuit is pro-

tected against overcurrent by a 3.2 amp circuit breaker (CB4).

Breaker can be reset. If it trips, determine cause of trouble

before resetting. A typical 24-v control wiring schematic is

shown in Fig. 59 and 60.

Compressor Lockout Logic — If any of the safe-

ties trip, the circuit will automatically reset (providing the

safety has reset) and restart the compressor in 15 minutes. If

any of the safeties trip 3 times within a 90-minute period,

then the circuit will be locked out and will require manual

resetting by turning off either the unit disconnect or the con-

trol circuit breaker, or opening the thermostat.

Replacement Parts — A complete list of replacement

parts may be obtained from any Carrier distributor upon

request.

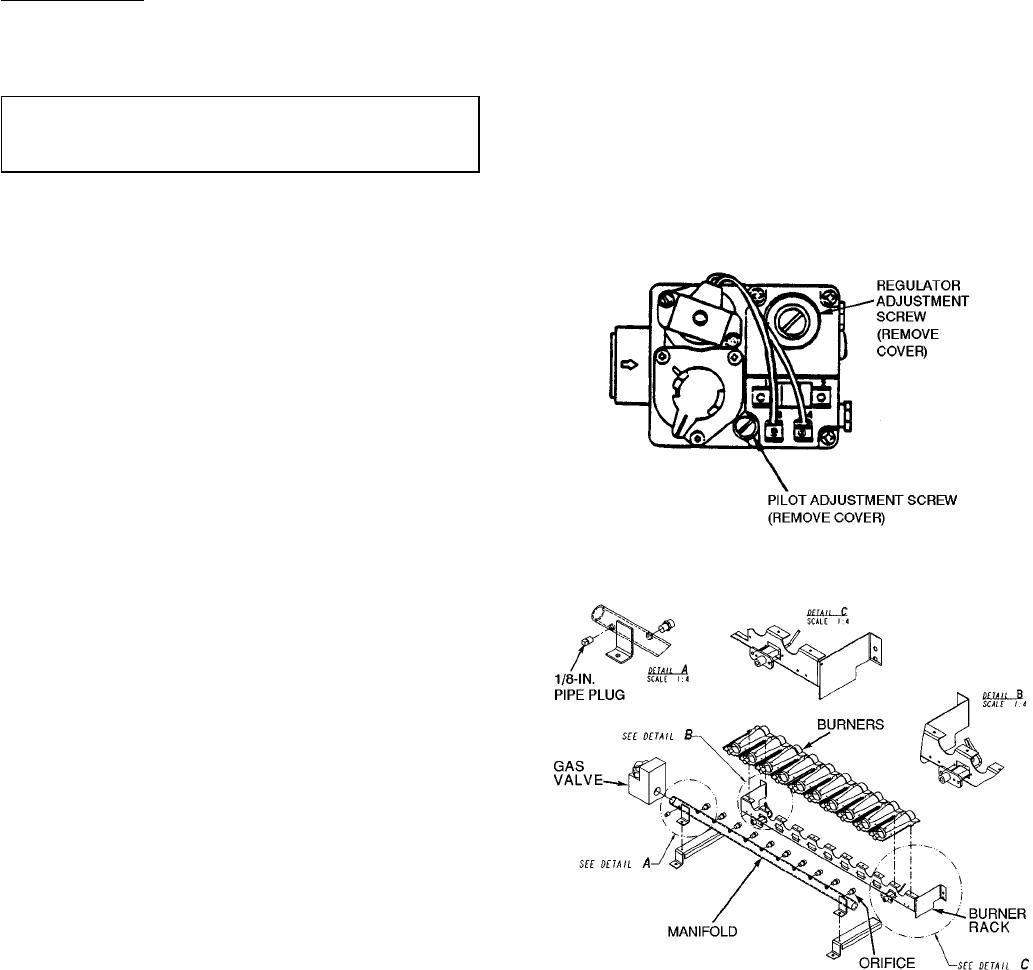

Fig. 54 — Gas Valve

Fig. 55 — Main Burner Removal

49