START-UP

Use the following information and Start-Up Checklist

on page CL-1 to check out unit PRIOR to start-up.

Unit Preparation — Check that unit has been installed

in accordance with these installation instructions and appli-

cable codes.

Compressor Mounting — Loosen the compressor hold-

down bolts until sidewise movement of the washer under

each holddown bolt head can be obtained. Do not loosen

completely as bolts are self-locking and will maintain

adjustment.

Service Valves — Ensure that the suction, discharge,

and liquid line service valves are open. Damage to the com-

pressor could result if they are left closed.

Internal Wiring — Check all electrical connections in

unit control boxes; tighten as required.

Refrigerant Service Ports — Each refrigerant sys-

tem has one suction port located in the top of the compressor

motor casing. All units also have one service port on the liq-

uid line valve and one on the compressor discharge valve.

Be sure that caps on the ports are tight.

Crankcase Heaters — Crankcase heaters are ener-

gized as long as there is power to the unit, except when the

compressors are operating.

IMPORTANT: Unit power must be on for 24 hours

prior to start-up. Otherwise, damage to compressor may

result.

Variable Frequency Drive (VFD) — The variable

frequency drives arefactory set.These settingsinclude factory-

installed jumpers and software configurations. The only

field configured set point is duct static pressure. An Opera-

tion Manual is shippedwith eachVAV unit. This manual should

be used if the drive needs to be customized for a particular

application.

NOTE: The VFD will always provide the proper phase

sequence to the indoor-fan motor. The indoor-fan motor op-

erates in proper rotation regardless of the phase sequence to

the unit. If, upon start-up, the outdoor fans operate back-

wards but the indoor fan operates in the correct direction,

reverse any two leads to the main terminal block. All fans

will then operate in the correct direction.

To set the duct static pressure, perform the following steps.

The factory setting is zero. The duct transducer has a range

from 0 to 5 in. wg. The transducer output is 4 to 20 mA,

therefore, 0 to 5 in. wg is proportional to the 4 to 20 mA and

must be expressed to the VFD in terms of percentage of the

frequency range. Refer to Table 7. The set point value is a

percentage of the maximum output frequency. Locate the duct

static pressure closest to that desired and use the correspond-

ing set point value. If necessary, interpolation between duct

static pressures is permissible.

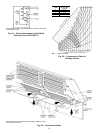

Fig. 40A — Motormaster III Sensor Location

(Sizes 024-034)

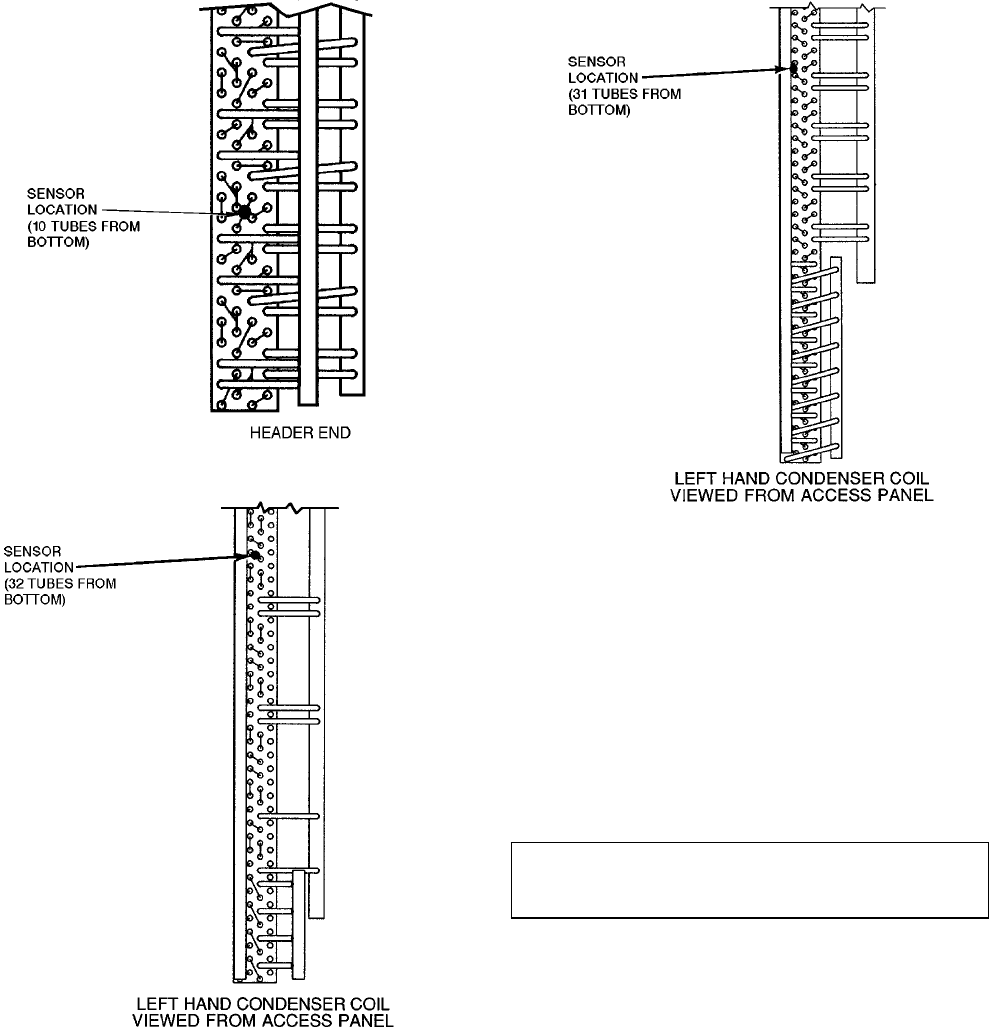

Fig. 40B — Motormasterா III Sensor Location

(Sizes 038 and 044)

Fig. 40C — Motormaster III Sensor Location

(Size 048)

31