39

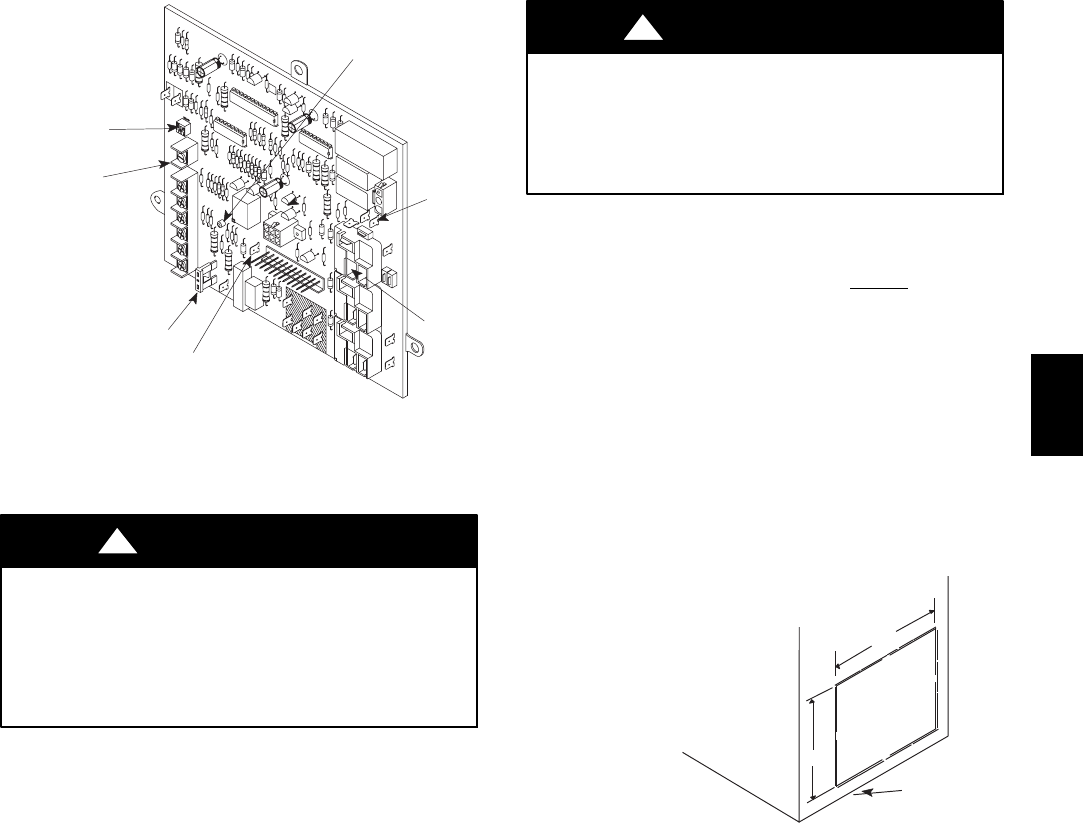

Dip Switch

See “Wiring

Diagram”

for switch settings

FUSE

115

VAC

HUM

DEHUM

Diagnostic Light

24 VAC

HUM

EAC

A07780

Fig. 41 -- Control Connections

DUCTWORK AND FILTER

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death.

Do NOT draw return air from inside a closet or utility room

where furnace is located. Return air duct MUST be sealed to

furnace casing.

!

WARNING

Installation

NOTE: Design and install the air distribution system to comply

with Air Conditioning Contractors of America manuals and/or

NFPA pamphlets 90A and 90B or other approved methods that

conform to local codes and good trade practices.

1. When furnace supply ducts carry air outside furnace area,

seal return air duct to furnace casing a nd terminate duct

outside furnace space.

2. Install air conditioning cooling coil (evaporator) on outlet

side of furnace.

3. For furnaces installed without a cooling coil, it is

recommended that the outlet duct be provided with a

removable access panel. This panel s hould be accessible

when the f urnace is installed so the exterior of the heat

exchanger can be viewed for inspections. The access panel

MUST be sealed to prevent leaks.

4. If separate evaporator and blower units are used, install good

sealing dampers for air flow control. Chilled air going

through the furnace could cause condensation and shorten

the furnace life.

NOTE: D ampers (field supplied) can be either automatic or

manual. Manually operated dampers MUST be equipped with a

means to prevent furnace or air conditioning operation unless

damper is in the full heat or cool position.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death.

Cool air passing over heat exchanger can cause condensate to

form resulting in heat exchanger failure.

!

WARNING

Connections

NOTE: Return air can enter through either side, both sides, the

botto m or a side and the bottom. Return air can not

enter through

rear of the furnace. When the furnace is located in an area near or

adjacent to the living a rea, the system should be carefully designed

with returns to minimize noise transmission through the return

grille. Any blower moving a high volume of air will produce

audible noise which could be objectionable to when the unit is

located very close to living areas. It is advisable to route the return

air ducts under the floor or through the attic.

1. For side connections using a 16″ x25″ (406.4 x 635mm)

filter, cut out the embossed area shown in Fig. 42. This will

provide a 14

1

/

2

″ x22

1

/

2

″ (368.3 x 571.5mm) approximate

opening.

Embossed Area

on Side of Furnace

A

=14 /

2

″ (368.3mm)HeightofCutout for16″x25″(406.4x 635mm)Filter

B=22

1

/

2

″ (571.5mm)Width of Cutoutfor 16″ x25″ (406.4x 635mm) Filter

A

Furnace

Bottom

B

A07728

Fig. 42 -- Side Return Air Cutout

NOTE: Furnaces with 5 TONS cooling capacity may require

two(2) side returns or one side return with bottom return.

2. Bottom returns can be made by removing the knockout

panel in the furnace base. Do NOT remove knock-out

except for a bottom return.

3. Installation of locking-type dampers are recommended in all

branches, or in individual ducts to balance system’s air flow.

4. Non-combustible, flexible duct connectors are

recommended for return and supply connections to furnace.

5. If air return grille is located close to the fan inlet, install at

least one, 90° air turn between fan and inlet grille to reduce

noise.

NOTE: To further reduce noise, install acoustical air turning vanes

and/or line the inside of duct with acoustical material.

Sizing

Existing or new ductwork MUST be sized to handle the correct

amount of airflow for either heating only or heating and air

conditioning.

Insulation

1. Insulate ductwork installed in attics or other areas exposed to

outside temperatures with a minimum of 2″ (50.8mm)

insulation and vapor barrier.

58HDV