10. For Heat Pump Units remove the capillary tube

only.

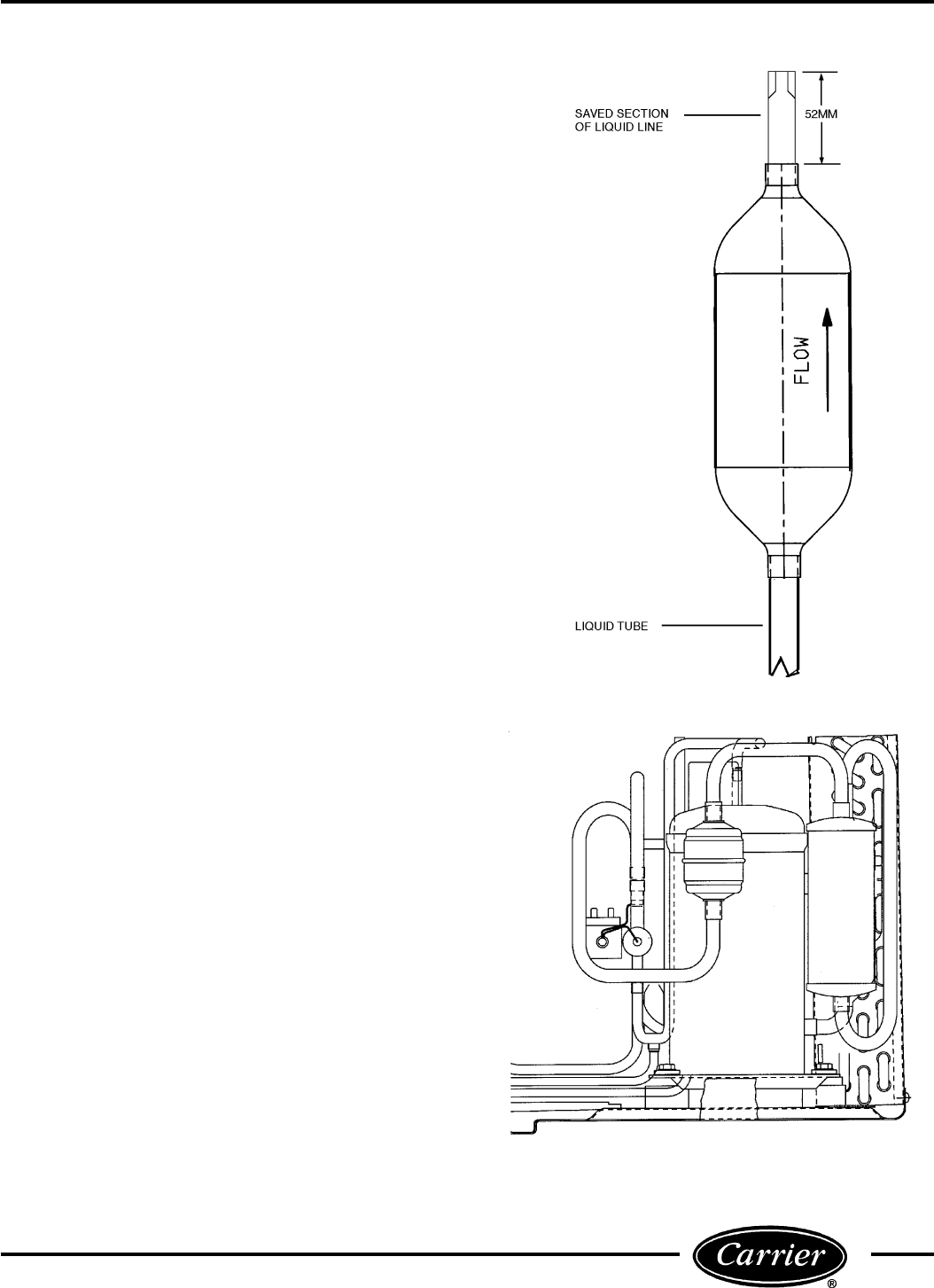

11. For Heat/Cool Units the filter drier is installed in

the liquid line, in place of the strainer. Trim the

saved liquid line tube from Step 9, to be 1.5 in. long

(saving the crimped portion), and braze it into the

filter drier, Part No. KH43LG060. See Figure 39.

For Heat Pump Units: A suction line filter drier

(Part No. Sporlan C-164S) is used and is installed

between the reversing valve and the com-

pressor accumulator. There are several suction

tube configurations and the suction line filter drier

will be field piped and brazed into the suction

tube for your unit. See Figure 40 for a general instal-

lation view.

12. Remove the grommets from the existing compressor

and install them onto the new compressor.

13. Install the new compressor and the new capillary

assembly (the correct capillary may be obtained

from Carrier RCD), into the unit.

14. Leak check the unit with 150 psi of nitrogen

pressure.

15. For 52S units, the system should be evacuated from

the high side to the low side to a minimum of

200 microns of mercury. This evacuation removes

residual moisture from the system prior to charging.

16. For Heat Pump Units: Recharge unit to the name-

plate refrigerant charge using a charging cylinder.

For Cooling Only and Heat/Cool Units: Add

one ounce of refrigerant to the nameplate charge to

compensate for the size of the liquid line drier.

17. Pinch off each access valve on the process tubes, in

2 places, using a pinch off tool such as Imperial tool

#105-FF or Robinair Tool #12294. Release any re-

frigerant pressure trapped in the access valve by

depressing the valve core, then confirm that no

R-22 is leaking past the pinch off tool location. Cut

the access valve stem of the process tube above

the top crimp and braze the top of each process tube

to ensure the system is sealed, (leave the pinch off

tool in place until after the brazing process is

complete).

18. Reassemble the unit by reversing steps1-9.

19. Connect the compressor wires and energize the unit

to verify operation.

Ⅲ REFRIGERANT CHARGING — Every mechanical

refrigeration system that is opened for servicing must

be accurately charged before it is returned to service.

Run the compressor ONLY after charging the system

with refrigerant. The compressor should never be

operated on air!

It is important to remember that recovered and/or re-

cycled refrigerant may only be recharged into the system

from which it was initially recovered, or another one

owned by the same customer. Charge level is important.

Charge units only as recommended by manufacturer.

FIGURE 39 — INSTALLED FILTER DRIER

FIGURE 40 — SUCTION LINE FILTER DRIER

21