12

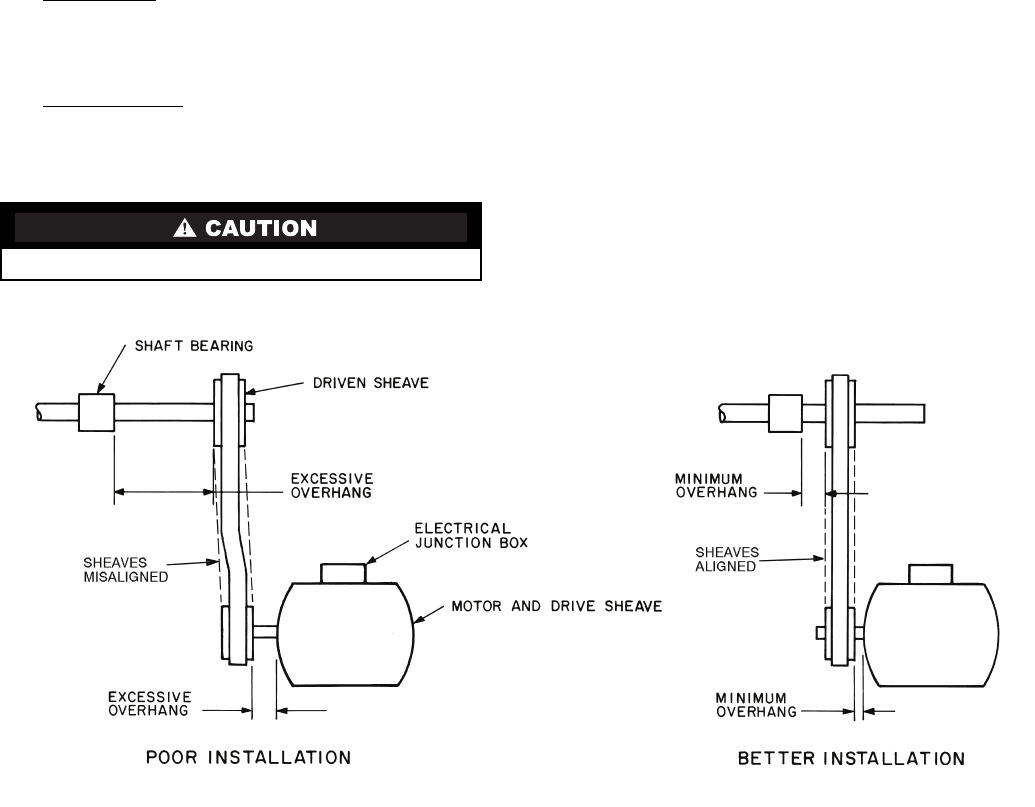

When field installing or replacing sheaves, install sheaves

on fan shaft and motor shaft for minimum overhang. (See

Fig. 13.) Use care when mounting sheave on fan shaft; too

much force may damage bearing. Remove rust-preventative

coating or oil from shaft. Make sure shaft is clean and free of

burrs. Add grease or lubricant to bore of sheave before

installing.

The 39L fan, shaft, and drive pulley are balanced as a com-

plete assembly to a high degree of accuracy. If excessive unit

vibration is present after fan pulley replacement, the unit must

be rebalanced. For drive ratio changes, always reselect the mo-

tor pulley — do not change the fan pulley.

ALIGNMENT — Make sure that fan shafts and motor shafts

are parallel and level. The most common causes of mis-

alignment are nonparallel shafts and improperly located

sheaves. Where shafts are not parallel, belts on one side are

drawn tighter and pull more than their share of the load. As a

result, these belts wear out faster, requiring the entire set to be

replaced before it has given maximum service. If misalignment

is in the sheave, belts will enter and leave the grooves at an

angle, causing excessive belt cover and sheave wear.

1. Shaft alignment can be checked by measuring the

distance between the shafts at 3 or more locations. If the

distances are equal, then the shafts will be parallel.

2. Sheave alignment:

Fixed sheaves

— To check the location of the fixed

sheaves on the shafts, a straightedge or a piece of string

can be used. If the sheaves are properly lined up the string

will touch them at the points indicated by the arrows in

Fig. 14.

Adjustable sheave

— To check the location of adjustable

sheave on shaft, make sure that the centerlines of both

sheaves are in line and parallel with the bearing support

channel. See Fig. 14. Adjustable pitch drives are installed

on the motor shaft.

3. Rotating each sheave a half revolution will determine

whether the sheave is wobbly or the drive shaft is bent.

Correct any misalignment.

4. With sheaves aligned, tighten cap screws evenly and

progressively.

NOTE: There should be a

1

/

8

-in. to

1

/

4

-in. gap between

the mating part hub and the bushing flange. If gap is

closed, the bushing is probably the wrong size.

5. With taper-lock bushed hubs, be sure the bushing bolts

are tightened evenly to prevent side-to-side pulley wob-

ble. Check by rotating sheaves and rechecking sheave

alignment. When substituting field-supplied sheaves for

factory-supplied sheaves, consider that the fan shaft

sheave has been factory balanced with fan and shaft as an

assembly. For this reason, substitution of motor sheave is

prefer-able for final speed adjustment.

Install V-Belts — When installing or replacing belts, al-

ways use a complete set of new belts. Mixing old and new belts

will result in the premature wear or breakage of the newer

belts.

1. Always adjust the motor position so that V-belts can be

installed without stretching over grooves. Forcing belts

can result in uneven stretching and a mismatched set of

belts.

2. Do not allow belt to bottom out in sheave.

3. Tighten belts by turning motor-adjusting jackscrews.

Turn each jackscrew an equal number of turns.

4. Equalize belt slack so that it is on the same side of belt for

all belts. Failure to do so may result in uneven belt

stretching.

5. Tension new drives at the maximum deflection force

recommended (Fig. 15).

With adjustable sheave, do not exceed maximum fan rpm.

Fig. 13 — Determining Sheave-Shaft Overhang