—46—

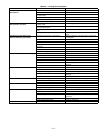

Table 33 — Heating Service Analysis

Table 34 — Perfect Humidity™ Adaptive Dehumidification System Subcooling Mode Service Analysis

Table 35 — Perfect Humidity Dehumidification System Hot Gas Reheat Mode Service Analysis

PROBLEM CAUSE REMEDY

Burners Will Not

Ignite

Misaligned spark electrodes. Check flame ignition and sensor electrode positioning. Adjust as needed.

No gas at main burners. Check gas line for air purge as necessary. After purging gas line of

air, allow gas to dissipate for at least 5 minutes before attempting

to relight unit.

Check gas valve.

Water in gas line. Drain water and install drip leg to trap water.

No power to unit. Check power supply, fuses, wiring, and circuit breaker.

No 24 v power supply to control circuit. Check transformer. Transformers with internal overcurrent protection

require a cool-down period before resetting. Check 24-v circuit breaker;

reset if necessary.

Miswired or loose connections. Check all wiring and wirenut connections.

Burned-out heat anticipator in thermostat. Replace thermostat.

Broken thermostat wires. Run continuity check. Replace wires, if necessary.

Inadequate Heating Dirty air filter. Clean or replace filter as necessary.

Gas input to unit too low. Check gas pressure at manifold. Clock gas meter for input. If too low,

increase manifold pressure or replace with correct orifices.

Unit undersized for application. Replace with proper unit or add additional unit.

Restricted airflow. Clean filter, replace filter, or remove any restrictions.

Blower speed too low. Use high speed tap, increase fan speed, or install optional blower, as suit-

able for individual units, Adjust pulley.

Limit switch cycles main burners. Check rotation of blower, thermostat heat anticipator settings,

and temperature rise of unit. Adjust as needed.

Too much outdoor air. Adjust minimum position.

Check economizer operation.

Poor Flame

Characteristics

Incomplete combustion (lack of

combustion air) results in:

Aldehyde odors, CO (carbon monoxide),

sooting flame, or floating flame.

Check all screws around flue outlets and burner compartment.

Tighten as necessary.

Cracked heat exchanger. Replace heat exchanger.

Overfired unit — reduce input, change orifices, or adjust gas line or mani-

fold pressure.

Check vent for restriction. Clean as necessary.

Check orifice to burner alignment.

Burners Will Not

Turn Off

Unit is locked into Heating mode for a

one minute minimum.

Wait until mandatory one-minute time period has elapsed or reset power to

unit.

PROBLEM CAUSE REMEDY

Subcooling Mode (Liquid Reheat)

Will Not Energize.

No power to control transformer from

evaporator-fan motor.

Check power source and evaporator-fan relay. Ensure all

wire connections are tight.

No power from control transformer to liquid line

solenoid valve.

1. Fuse open; check fuse. Ensure continuity of wiring.

2. Low-pressure switch open. Cycle unit off and allow low-

pressure switch to reset. Replace switch if it will not

close.

3. Transformer bad; check transformer.

Liquid line solenoid valve will not operate. 1. Solenoid coil defective; replace.

2. Solenoid valve stuck open; replace.

Liquid line solenoid valve will not open. Valve is stuck closed; replace valve.

Low System Capacity. Low refrigerant charge or frosted evaporator coil. 1. Check charge amount. Charge per Fig. 52-55.

2. Evaporator coil frosted; check and replace low-

pressure switch if necessary.

Loss of Compressor Superheat

Conditions with Subcooling/Reheat

Dehumidification Coil Energized.

Thermostatic expansion valve (TXV). 1. Check TXV bulb mounting, and secure tightly to suction

line.

2. Replace TXV if stuck open or closed.

PROBLEM CAUSE REMEDY

Reheat Mode Will Not Energize. No power to control transformer from

evaporator-fan motor.

Check power source and evaporator-fan relay. Ensure all

wire connections are tight.

No power from control transformer to hot gas

line solenoid valve.

1. Fuse open; check fuse. Ensure continuity of wiring.

2. Low-pressure switch open. Cycle unit off and allow low-

pressure switch to reset. Replace switch if it will not

close.

3. Transformer bad; check transformer.

Hot gas line solenoid valve will not operate. 1. Solenoid coil defective; replace.

2. Solenoid valve stuck closed; replace.

Low refrigerant charge or frosted evaporator coil. 1. Check charge amount. Charge per Fig. 52-55.

2. Evaporator coil frosted; check and replace low-

pressure switch if necessary.

Loss of Compressor Superheat

Conditions with Subcooling/Reheat

Dehumidification Coil Energized.

Thermostatic expansion valve (TXV). 1. Check TXV bulb mounting, and secure tightly to suction

line.

2. Replace TXV if stuck open or closed.

Excessive Superheat. Liquid line solenoid valve will not operate. Valve is stuck; replace valve.

Hot gas line solenoid valve will not close. Valve is stuck; replace valve.