—9—

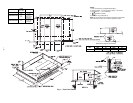

Route power and ground lines through control box end panel

or unit basepan (see Fig. 4 and 5) to connections as shown on

unit wiring diagram and Fig. 14.

Field wiring must conform to temperature limitations for

type “T” wire. All field wiring must comply with NEC and

local requirements.

Transformer no. 1 is wired for 230-v unit. If 208/230-v unit is

to be run with 208-v power supply, the transformer must be

rewired as follows:

1. Remove cap from red (208 v) wire.

2. Remove cap from orange (230 v) spliced wire.

3. Replace orange wire with red wire.

4. Recap both wires.

IMPORTANT: BE CERTAIN UNUSED WIRES ARE

CAPPED. Failure to do so may damage the transformers.

Operating voltage to compressor must be within voltage

range indicated on unit nameplate. On 3-phase units, volt-

ages between phases must be balanced within 2%.

Unit failure as a result of operation on improper line voltage

or excessive phase imbalance constitutes abuse and may

cause damage to electrical components. Such operation

would invalidate any warranty.

B. Field Control Wiring

The unit must have a separate electrical service with a field-

supplied, waterproof, fused disconnect switch mounted at, or

within sight from, the unit. Refer to the unit rating plate for

maximum fuse/circuit breaker size and minimum circuit

amps (ampacity) for wire sizing. Be sure disconnect switch

does not obstruct unit rating plate.

The field-supplied disconnect switchbox may be mounted on

the unit over the high-voltage inlet hole in the control corner

panel.

Connect ground lead to chassis ground connection when

using separate ground wire. The unit has a terminal block

for field power connections. Install conduit connectors in side

panel power supply knockout openings indicated in Fig. 4

and 5. Route power lines through connector to unit control

box.

Install a Bryant approved accessory thermostat assembly

according to the installation instructions included with the

accessory. Locate thermostat assembly on a solid wall in the

conditioned space to sense average temperature.

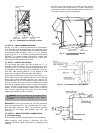

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals through conduit in unit to low-

voltage connections as shown on unit label wiring diagram

and in Fig. 15.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C Minimum).

All wire larger than no. 18 AWG cannot be directly connected

at the thermostat and will require a junction box and splice

at the thermostat.

Set heat anticipator settings as follows:

The room thermostat heat anticipator must be properly

adjusted to ensure proper heating performance. Set the heat

anticipator to settings based on the table above, by using an

ammeter to determine the exact setting for stages 1 and 2.

Failure to make a proper heat anticipator adjustment may

result in improper operation, discomfort to the occupants of

the conditioned space, and inefficient energy utilization;

however, the required setting may be changed slightly to pro-

vide a greater degree of comfort for a particular installation.

Refer to Accessory Remote Control Panel instructions if

required.

STEP 9 — MAKE OUTDOOR-AIR INLET ADJUSTMENTS

A. Manual Outdoor-Air Damper

All units (except those equipped with a factory-installed

economizer) have a manual outdoor-air damper to provide

ventilation air.

Damper can be preset to admit up to 25% outdoor air into

return-air compartment. To adjust, loosen securing screws

and move damper to desired setting. Retighten screws to

secure damper (Fig. 16).

B. Optional Economizer

Economizer Motor Control Module (See Fig. 17-19)

The economizer control location is shown Fig. 17. For maxi-

mum benefit of outdoor air, set economizer motor control

module to the “D” setting (Fig. 18). The economizer motor

control module is located on the economizer motor. See

Fig. 19.

CAUTION: The correct power phasing is critical in

the operation of the scroll compressors. An incorrect

phasing will cause the compressor to rotate in the

wrong direction. This may lead to premature compres-

sor failure.

WARNING: The unit must be electrically grounded

in accordance with local codes and NEC ANSI/NFPA

70 (National Fire Protection Association).

VOLTAGE W1 W2

208/230

0.98 0.44

460

0.80 0.44

NOTE:

The maximum wire size for TB1 is 2/0.

LEGEND

Fig. 14 — Field Power Wiring Connections

EQUIP —

Equipment

GND —

Ground

NEC —

National Electrical Code

TB —

Terminal Board

Fig. 15 — Field Control Thermostat Wiring