—8—

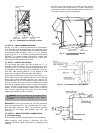

VI. STEP 6 — TRAP CONDENSATE DRAIN

See Fig. 4, 5, and 11 fore drain location. Plug is provided in

drain hole and must be removed when unit is operating. One

3

/

4

in. half coupling is provided inside unit evaporator section

for condensate drain connection. An 8

1

/

2

in. x

3

/

4

in. diameter

nipple and a 2 in. x

3

/

4

in. diameter pipe nipple are coupled to

standard

3

/

4

in. diameter elbow to provide a straight path

down through holes in unit base rails (see Fig. 11 and 12). A

trap at least 4 inches deep must be used.

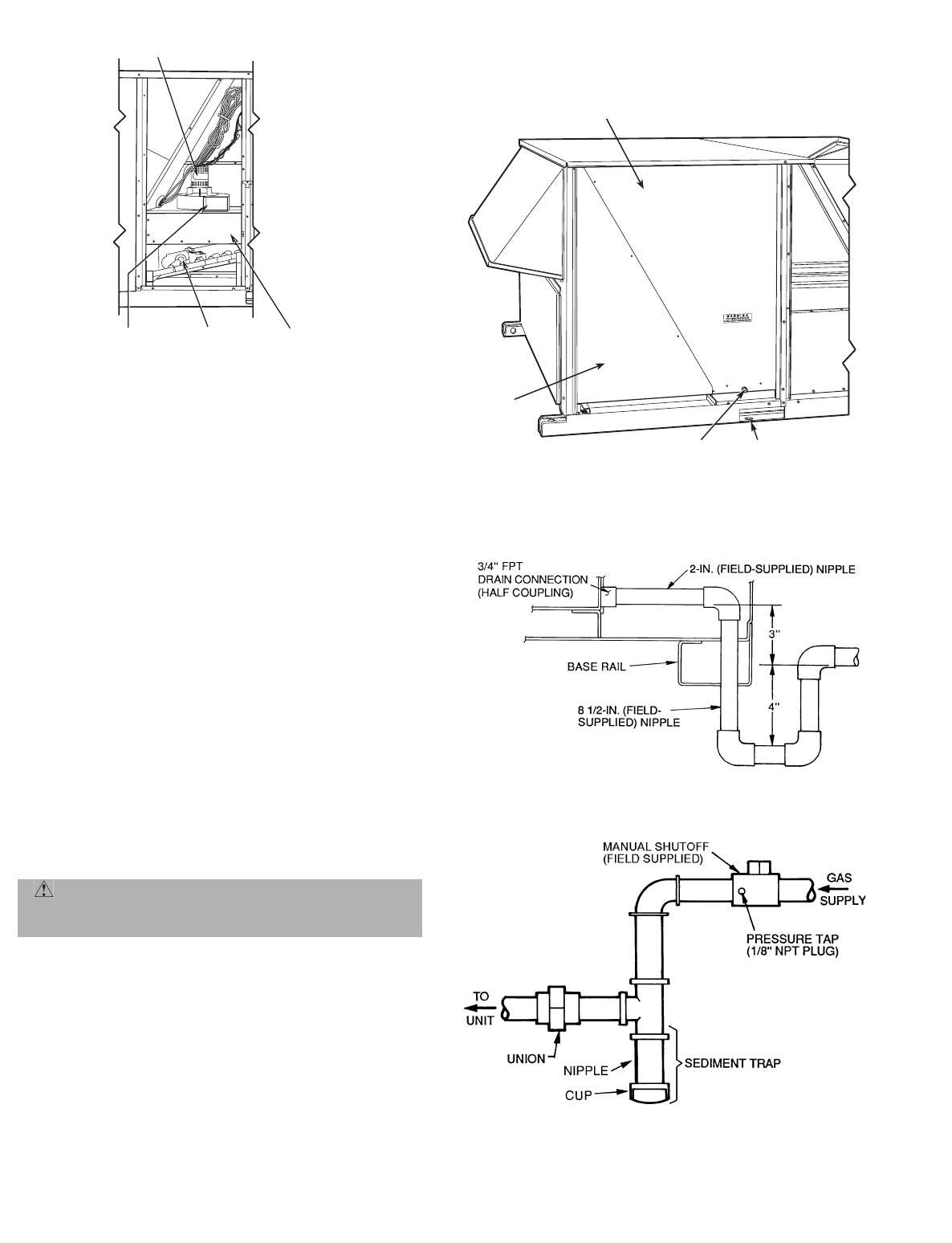

VII. STEP 7 — INSTALL GAS PIPING

The gas supply pipe enters the unit through the 1

1

/

2

in.

diameter knockout provided. The gas connection to the unit

is made to the

3

/

4

in. FPT gas inlet on the gas manifold. Unit

is equipped for use with natural gas. Installation must con-

form with local building codes or, in the absence of local

codes, with the National Fuel Gas code, ANSI Z223.1.

Install field-supplied manual gas shutoff valve with a

1

/

8

in.

NPT pressure tap for test gage connection at unit. Field gas

piping must include sediment trap and union. See Fig. 13.

Install sediment trap in riser leading to heating section. This

drip leg functions as a trap for dirt and condensate. Install

trap where condensate cannot freeze. Install this sediment

trap by connecting a piping tee to riser leading to heating

section, so that straight-through section of tee is vertical.

Then, connect capped nipple into lower end of tee. Extend

capped nipple below level of gas controls.

IMPORTANT: Natural gas pressure at unit gas connection

must not be less than 5.5 in. wg or greater than 13.5 in. wg.

Size gas-supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas

connection.

VIII. STEP 8 — MAKE ELECTRICAL CONNECTIONS

A. Field Power Supply

Unit is factory wired for voltage shown on unit nameplate.

When installing units, provide a disconnect per NEC

(National Electrical Code) requirements of adequate size

(Table 2).

All field wiring must comply with NEC and local require-

ments. Insulate low-voltage wires for highest voltage con-

tained within conduit when low-voltage control wires are run

in the same conduit as high-voltage wires.

WARNING: Do not pressure test gas supply while

connected to unit. Always disconnect union before

servicing.

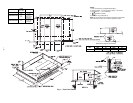

INDUCED DRAFT

MOTOR

MAIN BURNER

SECTION

COMBUSTION

FAN HOUSING

HEAT EXCHANGER

SECTION

Fig. 10 — Combustion Fan Housing Location

3/4" FPT DRAIN

CONNECTION

1-3/8"

DRAIN HOLE

INDOOR MOTOR ACCESS

FILTER

ACCESS

Fig. 11 — Condensate Drain Details

(581A155 Shown)

Fig. 12 — Condensate Drain Piping Details

Fig. 13 — Field Gas Piping