—25—

Upon a second-stage call for cooling, compressor no. 1 is

energized and mechanical cooling is integrated with econo-

mizer cooling. If the outdoor-air temperature drops below

50 F, a cooling lockout switch prevents the compressors from

running.

When supply-air temperature drops below a fixed set point,

the economizer damper modulates to maintain the tempera-

ture at the fixed set point.

D. Freeze Protection Thermostats

A freeze protection thermostat is located on the top and bot-

tom of the evaporator coil. It detects frost build-up and locks

out the compressors, allowing the coil to clear. Once frost has

melted, the compressors can be reenergized by resetting the

compressor lockout.

E. Heating, Units With Economizer

Outdoor-air damper stays at VENT position while evapora-

tor fan is operating. Refer to Heating, Units without Econo-

mizer section on page 24 for heating sequence of operation.

SERVICE

I. CLEANING

Inspect unit interior at beginning of each heating and cooling

season and as operating conditions require. Remove unit top

panel and/or side panels for access to unit interior.

A. Evaporator Coil

Clean as required with commercial coil cleaner. Wash both

sides of coil and flush with clean water.

B. Condenser Coil

Clean condenser coil annually and as required by location

and outdoor-air conditions. Inspect coil monthly; clean as

required.

C. Condensate Drain

Check and clean each year at start of cooling season. In win-

ter, keep drains and traps dry.

D. Filters

Clean or replace at start of each heating and cooling season,

or more often if operating conditions require. Refer to Table 1

for type and size.

E. Outdoor-Air Inlet Screens

Clean screens with steam or hot water and a mild detergent.

Do not use throwaway filters in place of screens. See Table 1

for quantity and size.

F. Main Burner

At the beginning of each heating season, inspect for deterio-

ration or blockage due to corrosion or other causes. Observe

the main burner flames. Refer to Main Burners section on

page 29.

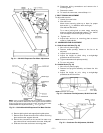

G. Flue Gas Passageways

The flue collector box and heat exchanger cells may be

inspected by removing heat exchanger access panel (Fig. 4

and 5), flue box cover, and main burner assembly (Fig. 28).

Refer to Main Burners section on page 29 for burner removal

sequence. If cleaning is required, remove heat exchanger baf-

fles and clean tubes with a wire brush.

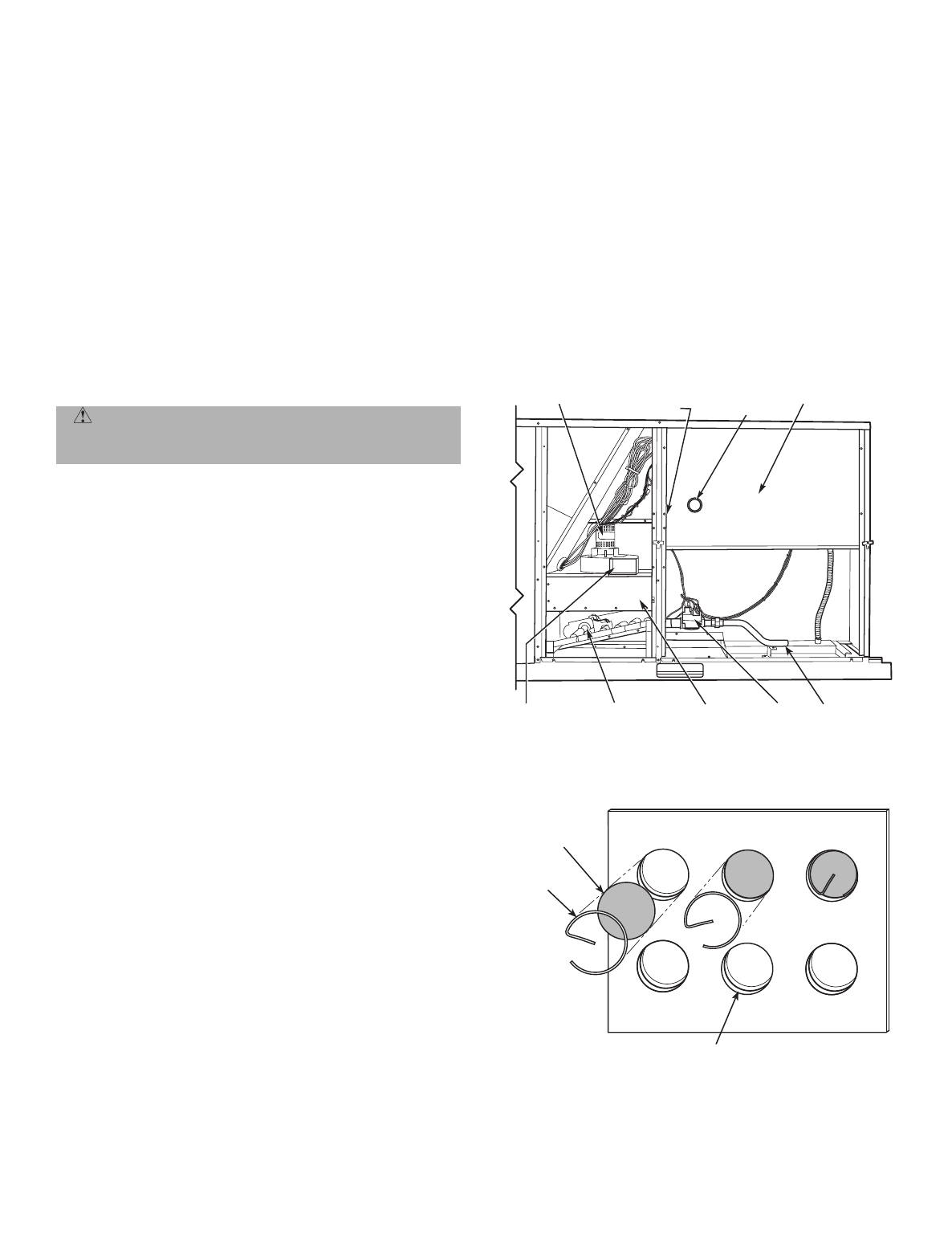

Use caution with ceramic heat exchanger baffles. When

installing retaining clip, be sure the center leg of the clip

extends inward toward baffle. See Fig. 29.

H. Combustion-Air Blower

Clean periodically to assure proper airflow and heating effi-

ciency. Inspect blower wheel every fall and periodically dur-

ing heating season. For the first heating season, inspect

blower wheel bi-monthly to determine proper cleaning

frequency.

To inspect blower wheel, remove heat exchanger access

panel. Shine a flashlight into opening to inspect wheel. If

cleaning is required, remove motor and wheel assembly by

removing screws holding motor mounting plate to top of com-

bustion fan housing (Fig. 28). The motor and wheel assembly

will slide up and out of the fan housing. Remove the blower

wheel from the motor shaft and clean with a detergent or sol-

vent. Replace motor and wheel assembly.

WARNING: Before performing service or mainte-

nance operations on unit, turn off main power switch

to unit. Electrical shock could cause personal injury.

INDUCED DRAFT

MOTOR

FLUE BOX

COVER

MAIN BURNER

SECTION

MAIN GAS

VALVE

COMBUSTION

FAN HOUSING

INTEGRATED GAS

UNIT CONTROLLER

(HIDDEN)

CONTROL BOX

ACCESS PANEL

IGC LED

VIEW

PORT

FIELD GAS

CONNECTION

CERAMIC

BAFFLE

CLIP

HEAT EXCHANGER

TUBES

Fig. 28 — Typical Gas Heating Section

NOTE:

One baffle and clip will be in each upper tube of the heat

exchanger.

Fig. 29 — Removing Heat Exchanger Ceramic Baffles

and Clips