—15—

NOTE: When compressors are rotating in the wrong direc-

tion, the unit will have increased noise levels and will not

provide heating and cooling.

After a few minutes of reverse operation, the scroll compres-

sor internal overload protection will open, which will acti-

vate the unit’s lockout and requires a manual reset. Reset is

accomplished by turning the thermostat on and off.

VI. INTERNAL WIRING

Check all electrical connections in unit control boxes; tighten

as required.

VII. CRANKCASE HEATER(S)

Crankcase heater(s) is energized as long as there is power to

the unit and the compressor is not operating.

IMPORTANT: Unit power must be on for 24 hours prior to

start-up. Otherwise, damage to compressor may result.

VIII. EVAPORATOR FAN

Fan belt and variable pulleys are factory-installed. Remove

tape from the fan pulley. See Tables 3-10 for Fan Perfor-

mance Data. Be sure that fans rotate in the proper direction.

See Table 11 for air quantity limits. See Table 12 for Evapo-

rator Fan Motor Specifications. See Table 13 for static pres-

sure information for accessories and options. See Table 14 for

fan rpm at various motor pulley settings. To alter fan perfor-

mance, see Evaporator Fan Performance Adjustment section

on page 26.

NOTE: A 3

1

/

2

-in. bolt and threaded plate are included in the

installer’s packet. They can be added to the motor support

channel below the motor mounting plate to aid in raising the

fan motor.

IX. CONDENSER FANS AND MOTORS

Condenser fans and motors are factory set. Refer to Con-

denser-Fan Adjustment section (page 27) as required. Be

sure that fans rotate in the proper direction.

X. RETURN-AIR FILTERS

Check that correct filters are installed in filter tracks (see

Table 1). Do not operate unit without return-air filters.

XI. OUTDOOR-AIR INLET SCREENS

Outdoor-air inlet screens must be in place before operating

unit.

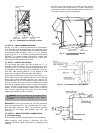

XII. ACCESSORY ECONOMIZER ADJUSTMENT

Remove filter access panel. Check that outdoor-air damper is

closed and return-air damper is open.

Economizer operation and adjustment are described in Base

Unit Operation section on page 24, and in Economizer

Adjustment section on page 28.

Table 3 — Fan Performance — 581A155225 (Low Heat Units with Standard Indoor Fan Motor)

LEGEND

*Standard low-medium static drive range is 834 to 1064 rpm. Alternate

high-static drive range is 1161 to 1426. Other rpms require a field-

supplied drive.

NOTES:

1. Maximum continuous bhp for the standard motor is 3.13. The maxi-

mum continuous watts is 2700. Do not adjust motor rpm such that

motor maximum bhp and/or watts is exceeded at the maximum

operating cfm.

2. Static pressure losses (i.e., economizer) must be added to external

static pressure before entering Fan Performance table.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive motor and drive testing on these units ensures that the full

bhp and watts range of the motor can be utilized with confidence.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. Use of a field-supplied motor may affect wiring size. Contact your

Bryant representative for details.

CFM

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

0.20.40.60.81.0

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

3750

753 915 1.05 838 1066 1.23 945 1278 1.47 1044 1500 1.73 1138 1731 1.99

4000

755 991 1.14 865 1198 1.38 968 1414 1.63 1063 1639 1.89 1154 1873 2.15

4250

788 1129 1.30 894 1341 1.54 992 1562 1.80 1084 1791 2.06 1172 2029 2.33

4500

822 1280 1.47 923 1497 1.72 1017 1722 1.98 1106 1956 2.25 1191 2196 2.53

4750

857 1443 1.66 953 1666 1.92 1044 1896 2.18 1130 2133 2.45 1212 2377 2.73

5000

891 1620 1.86 984 1847 2.12 1071 2082 2.39 1154 2323 2.67 1234 2572 2.96

5250

927 1810 2.08 1015 2043 2.35 1099 2282 2.62 1180 2528 2.91 — — —

5500

962 2014 2.32 1047 2252 2.59 1129 2496 2.87 — — — — — —

5750

998 2233 2.57 1080 2476 2.85 — — — — — — — — —

6000

1035 2466 2.84 — — — — — — — — — — — —

CFM

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.21.41.61.82.0

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

3750

1226 1971 2.27 1311 2218 2.55 1391 2474 2.85

——————

4000

1240 2116 2.43 1322 2366 2.72 1401 2623 3.02 — — — — — —

4250

1255 2274 2.61 1335 2526 2.91 — — — — — — — — —

4500

1272 2444 2.81 1350 2700 3.10 — — — — — — — — —

4750

1291 2628 3.02 — — — — — — — — — — — —

5000

———————————————

5250

———————————————

5500

———————————————

5750

———————————————

6000

———————————————

Bhp —

Brake Horsepower

FIOP —

Factory-Installed Option

Watts —

Input Watts to Motor