—7—

III. STEP 3 — FIELD FABRICATE DUCTWORK

On vertical units, secure all ducts to roof curb and building

structure. Do not connect ductwork to unit. Use flexible duct

connectors between unit and ducts as required. Adequately

insulate and weatherproof all ductwork located outdoors,

joints, and roof openings with counter flashing and mastic in

accordance with applicable codes. Insulate ducts passing

through unconditioned space, and use vapor barrier in accor-

dance with the latest issue of SMACNA (Sheet Metal and Air

Conditioning Contractors National Association) and ACCA

(Air Conditioning Contractors of America) minimum instal-

lation standards for heating and air conditioning systems.

Ducts passing through an unconditioned space must be insu-

lated and covered with a vapor barrier.

A minimum clearance to combustibles of 1 in. for the first

24 in. of ductwork is required for all units with electric heat.

Cabinet return-air static shall not exceed –0.35 in. wg with

economizer or –0.45 in. wg without economizer.

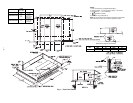

IV. STEP 4 — MAKE UNIT DUCT CONNECTIONS

Unit is shipped for thru-the-bottom duct connections. Duct-

work openings are shown in Fig. 1, 4, and 5. Duct

connections are shown in Fig. 6. Field-fabricated concentric

ductwork may be connected as shown in Fig. 7 and 8. Attach

all ductwork to roof curb and roof curb basepans. Refer to

installation instructions shipped with accessory roof curb for

more information.

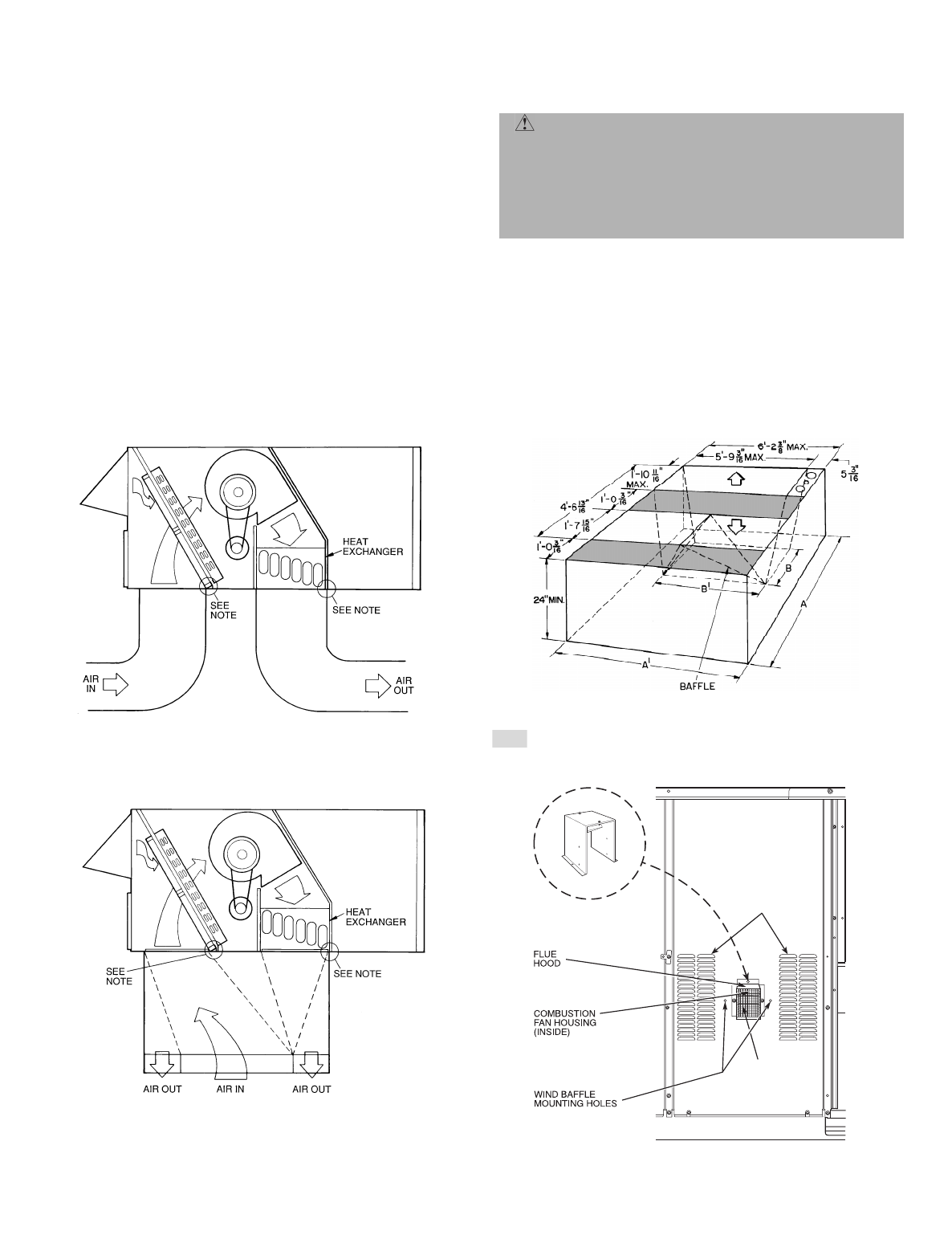

V. STEP 5 — INSTALL FLUE HOOD AND WIND BAFFLE

Flue hood, screen, and wind baffle are shipped secured

under main control box. To install, secure flue hood and

screen to access panel with screws provided. See Fig. 9. The

wind baffle is then installed over the flue hood.

NOTE: When properly installed, flue hood will line up with

combustion fan housing. See Fig. 10.

WARNING: For vertical supply and return units,

tools or parts could drop into ductwork and cause an

injury. Install a 90 degree turn in the return ductwork

between the unit and the conditioned space. If a

90 degree elbow cannot be installed, then a grille of

sufficient strength and density should be installed to

prevent objects from falling into the conditioned space.

WIND

BAFFLE

FLUE

SCREEN

INLET

LOUVERS

NOTE:

Do not drill in this area; damage to basepan may result in water

leak.

Fig. 6 — Air Distribution — Thru-the-Bottom

(581A180, 240 Unit Shown)

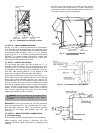

NOTE:

Dimensions A, A’, B and

B’ are obtained from field-supplied ceiling diffuser.

Shaded areas indicate block-off pans.

Fig. 8 — Concentric Duct Details

NOTE:

Do not drill in this area; damage to basepan may result in water

leak.

Fig. 7 — Concentric Duct Air Distribution

(581A180, 240 Unit Shown)

Fig. 9 — Flue Hood Location