17

emergency heating or cooling operation using a common

thermostat and the terminal strip connections on the two control

boards (See Non --Communicating Emergency Cooling/Heating

Mode) and will display Status Code 16, System Communication

Fault, on amber STATUS LED. No further troubleshooting

information will be available at UI until communications are

re--established.

If either COMM LED does not light within proper time period and

status codes are not displayed;

1. Check system transformer high-- and low-- voltage to be sure

the system is powered.

2. Check ABCD connection on both boards.

3. Check fuse on furnace board to be sure it is not blown. If

fuse is open, check system wiring before replacing it to be

sure a shor t do es not cause a failure of repl acement fuse.

If COMM LED does not light within proper time period and status

code is displayed:

1. Check system wiring to be sure UI is powered and

connections are made A to A, B to B, etc. and wiring is not

shorted. Miswiring or shorting of the ABCD

communications wiring will not allow successful

communications.

NOTE: Shorting or misw iring low--voltage system wiring will

not cause damage to unit control or UI but may cause low voltage

fuse to open.

C. Indoor Fan Motor Troubleshooting

The indoor fan is driven by an ECM motor consisting of two parts:

the control module and the motor winding section. Do not assume

motor or module is defective if it will not start. Use the

designed--in LED information aids and follow troubleshooting

steps described below before replacing motor control module or

entire motor. Motor control module is available as a replacement

part.

VERIFY MOTOR WINDING SECTION

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

After disconnecting power from the ECM motor, wait at

least 5 minutes before removing the control section. Internal

capacitors require time to discharge.

!

WARNING

Before proceed ing to r eplace a motor contro l module:

1. Check motor winding section to be sure it is functional.

2. Remove motor control module section and unplug winding

plug. Motor shaft should turn freely, resistance between any

two motor leads should be similar and resistance between

any motor lead and unpainted motor end should exceed

100,000 ohms.

3. Failing any of these tests, entire ECM motor must be

replaced.

4. Passing all of the tests, motor control module alone can be

replaced.

MOTOR TURNS SLOWLY

1. Low s tatic pr essure loading of blo wer while access panel is

removed will cause bl ower to run slowly. Particularly at low

airflow requests. This is normal, do not assume a fault

exists.

2. Recheck airflow and system static pressure using UI service

screens with access panel in place.

NOTE: Blower motor faults will not cause a lockout of blower

operation. The fan coil control will attempt to run the blower motor

as long as UI maintains a demand for airflow. The control will not

operate electric heaters while a fault condition exists. The control

communicates with the motor at least once every five seconds,

even when the motor is idle. If, during operation, the control does

not communicate with the motor for more than 25 seconds, the

motor will shut itself down and wait for communications to be

reestablishe d.

D. Furnace Control Troubleshooting

Furnace control faults indicated by flashing codes on the amber

system STATUS LED can be resolved using troubleshooting

information provided below. Codes are listed in order of their

priority, highest to lowest. Though multiple faults can exist at any

time, only the highest priority code will be displayed on STATUS

LED. Clearing the indicated faul t when multiple faults exist will

cause the next highest priority Status Code to be flashed. All

existing faults, as well as a faul t history, can be vi ewed at UI.

STATUS CODE CONTINUOUS OFF

Check for 230 VAC at L1 and L2, and 24 VAC at SEC--1 and

SEC--2.

STATUS CODE CONTINUOUS ON

Control has 24 VAC power.

STATUS CODE 11 -- NO PREVIOUS CODE

Stored status codes are erased automatically after 72 hours.

STATUS CODE 12 -- BLOWER ON AFTER POWER UP

(230 VAC or 24 VAC) Blower runs for 90 seconds if unit is

powered up during a call for heat (R--W/W1 clos ed) or (R--W/W1

opens) during blower on--delay period.

STATUS CODE 13 -- LIMIT CIRCUIT LOCKOUT

Lockout occurs if a limit or flame rollout switch is open longer

than 3 minut es or 10 successive limit trips occurred during high

heat. Control will auto reset after three hours. Refer to status code

33.

STATUS CODE 14 -- IGNITION LOCKOUT

Control will auto reset after three hours. Refer to status code 34.

STATUS CODE 15 -- BLOWER MOTOR LOCKOUT

Indi cates the blower failed to reach 250 RPM or the blower failed

to communicate within 30 seconds after being turned ON in two

successive heating cycles. Control will auto reset after 3 hours.

Refer to status code 41.

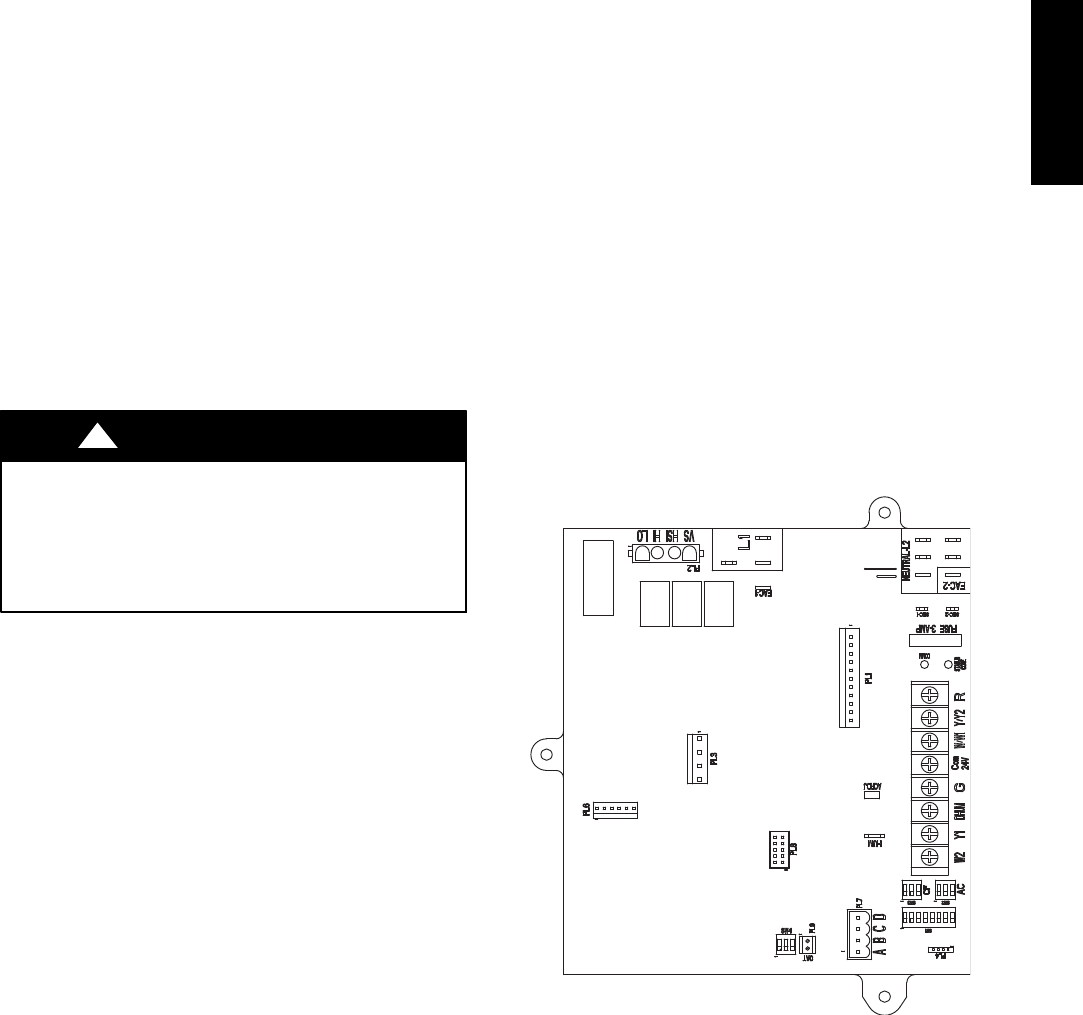

A06026

Fig. 15 -- Detail of Furnace Board

577D-- -- A