42

BAS-311E.311EL.326E.326EL

Chapter 3. Assembly

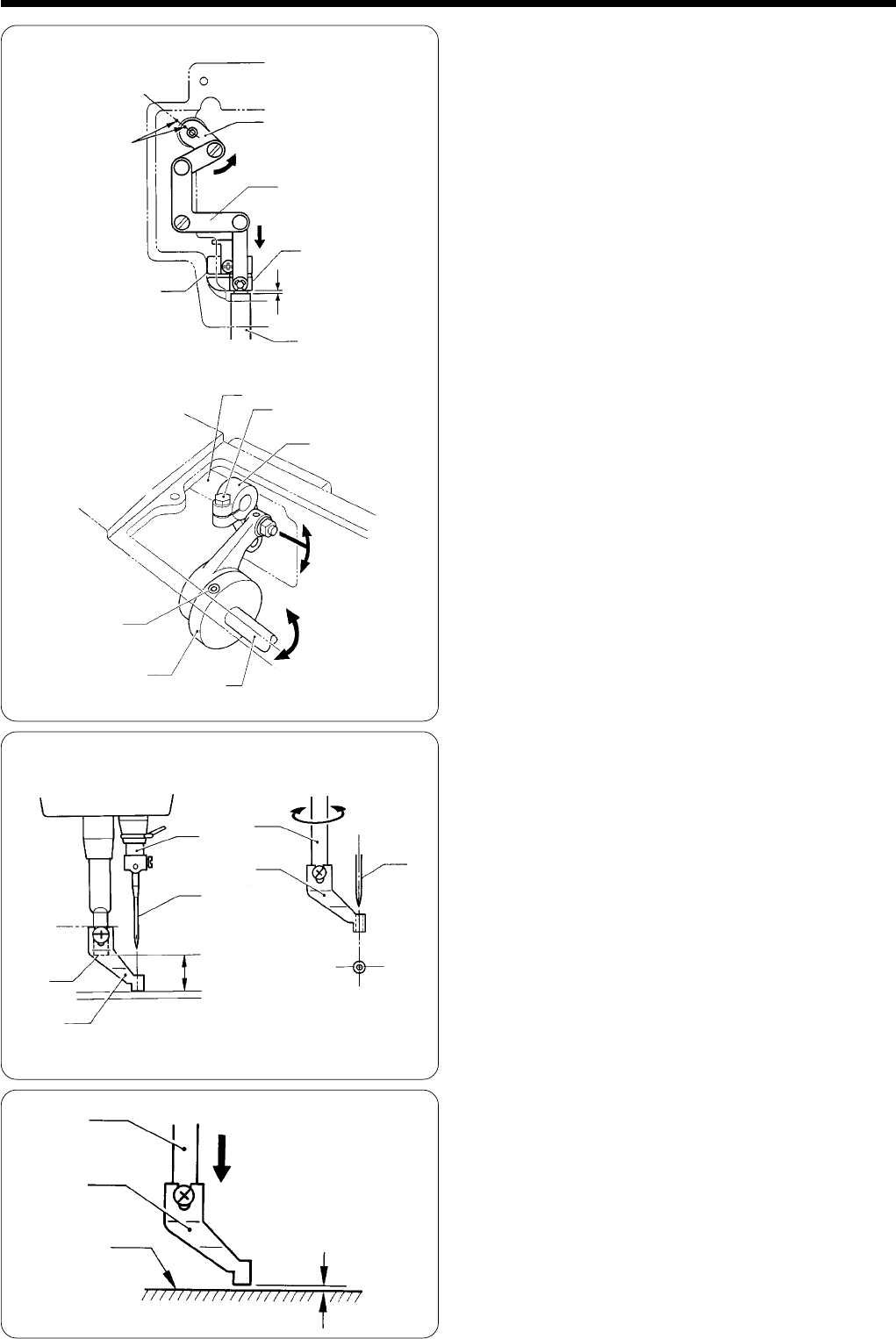

6. Turn the pulley to align the needle bar with the shuttle

hook. At this time, turn the stepping work clamp con-

necting rod !8 to turn stepping work clamp arm F !1 in

the direction of the arrow and move the stepping link

assy !6 in the direction of the arrow. When the presser

foot is at the lowest position, secure the stepping work

clamp connecting rod !8 to the upper shaft @0 using the

set screw !9.

Adjust the lift stroke of presser foot A to 3-5 mm, and 5-8

mm. When the clearance between the presser bar lifter

e and the presser bar bush q is 0.5 - 1 mm, tighten the

bolt !4 of stepping work clamp arm R !3. (At this time,

the match mark of stepping work clamp arm F !1 will be

almost aligned with that of arm.)

Note: Make sure that stepping work clamp arm F !0 has

no end play.

7. Secure the needle bar clamp t using the screw so that

when the presser bar w is at the lowest position. The

distance between the bottom of the presser bar w and

the top of the needle plate should be 23 mm. (22 mm for

311EL.)

Attach the presser foot @1 to the presser bar w so that

the top of the presser foot @1 is aligned with the top of

the screw that holds the presser foot @2.

8. Attach the needle @2 to the needle bar @3.

9. Turn the pulley to insert the needle @2 into the hole of the

presser foot @1. Turn the presser bar w so that the

needle @2 is in the center of the hole of the presser foot

@1, and tighten the screw of the needle bar clamp t.

10.Turn the pulley to set the presser bar w at its lowest po-

sition. Adjust the height of the presser foot @1 so that

there is a 0.5 mm clearance from the top of the material

to be sewn.

!1

!6

e

t

q

0.5 - 1mm

!1

@0

!3

!8

!4

!9

w

@1

@2

@3

w

@1

w

@1

0.5mm

V notch

@2

Align