107

BAS-311E.311EL.326E.326EL

Chapter 7

#4

The work

clamp does

not move

up and

down

when the

foot switch

is stepped

on.

Probable causes

4. Power PCB defective.

5. The air valve is defective.

6. The control circuit board (#3) is

defective.

Check/repair/adjust

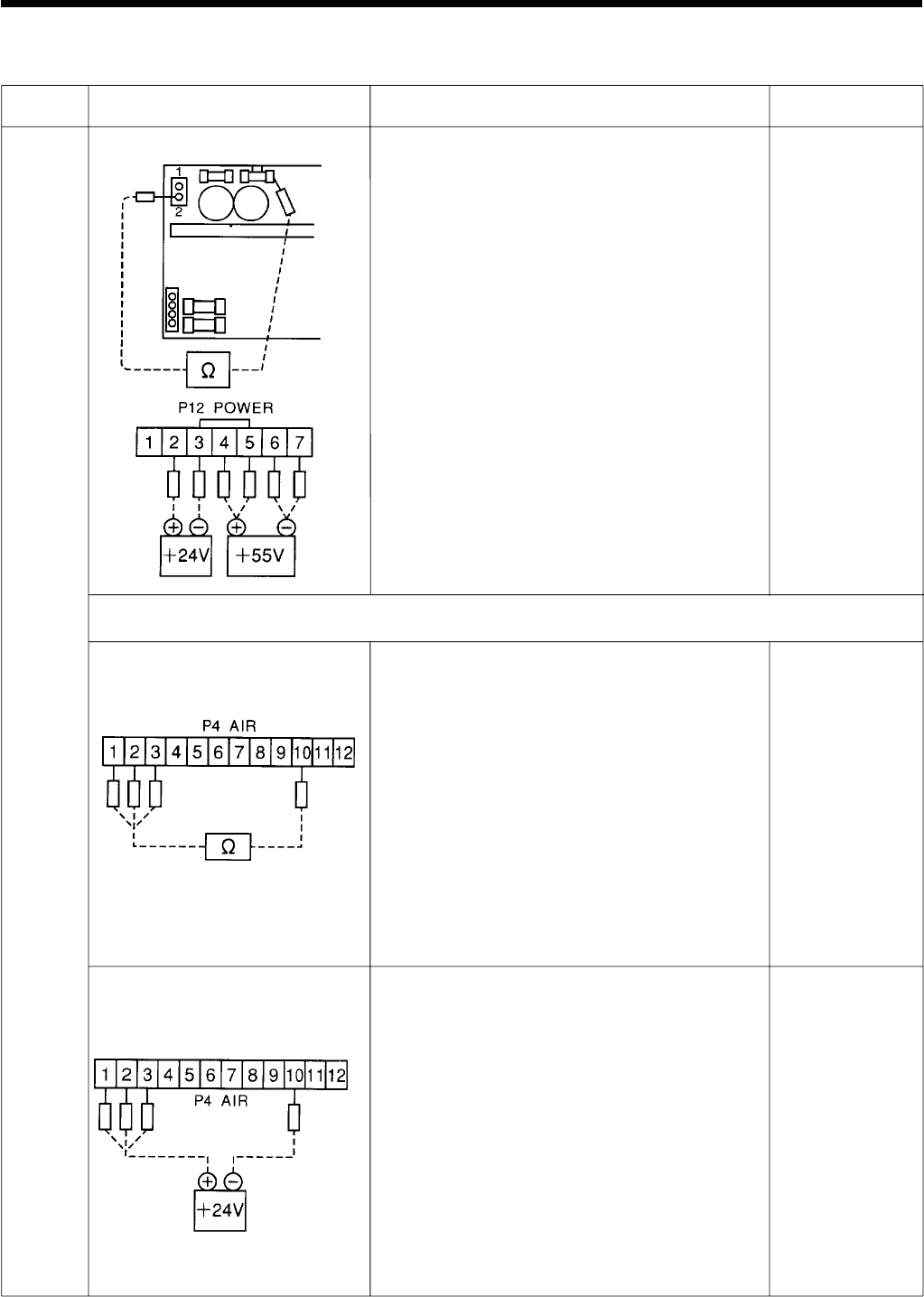

• Measure the resistance between a terminal in the

center of the power PCB and pin 2 in connector P5

(DC300).

The resistance should be ∞Ω.

• Remove connector P12 (POWER) on the control

circuit board, turn on the power, and measure the

voltage across pins 4 and 6, pins 5 and 6, pins 5

and 7 on the cord.

The voltage in each case should be +55V.

Measure the voltage across pins 2 and 3. The

voltage should be +20V to 24V.

After measurement, turn off the power, wait at

least 5 minutes, and insert P12.

• Pull out connector P4 (AIR) on the control circuit

board and measure the resistance between the

following pins in the connector on the cord:

Pins 1 and 10 (air valve for right work clamp)

Pins 2 and 10 (air valve for left work clamp)

Pins 3 and 10 (air valve for presser foot; only

for optional specification)

The resistance in each case should be 300 - 400 Ω.

• Pull out connector P4 (AIR) and measure the

voltage across the following pins in the connector

on the PCB:

Pins 1 and 10 (air valve for right work clamp)

Pins 2 and 10 (air valve for left work clamp)

Pins 3 and 10 (air valve for presser foot; only

for optional specification)

The voltage in each case should be +20V to 24V.

After measurement, turn off the power, wait at

least 5 minutes, and insert P4.

Parts to be replaced

Power PCB

Air valve

Valve harness assy.

Control circuit

board.

Error status

Work clamp for pneumatic specification (BAS-311E and 325E)