YORK INTERNATIONAL 29

FORM 160.49-O2

IMPORTANT!!!: Although this message is generally

indicative of a defective proximity probe, it is possible

that the compressor has been damaged. If the high

speed thrust bearing is not inspected by a qualified

service technician prior to starting the chiller, further

severe compressor damage could result. The chiller

cannot be restarted until the “Special Reset Proce-

dure” in YORK Service manual, Form 160.49-M3 is per-

formed by a qualified service technician.

MON XX:XX AM – HIGH SPEED DRAIN TEMP

The chiller has shut down because the “Proximity/Tem-

perature Sensor” has detected the temperature of the

high speed drain line has reached 250.0°F or greater.

IMPORTANT: If the chiller has shut down displaying

this message, it cannot be restarted until a qualified

service technician performs visual inspection of the

high speed thrust bearing and performs a special reset

procedure. This special reset procedure is detailed in

YORK Service manual, Form 160.49-M3. Failure to

perform the visual inspection prior to restarting the

chiller could result in severe compressor damage!!!

MON XX:XX AM – OPEN DRAIN TEMP THERMOCOUPLE

The chiller is shut down because the “Proximity/Tem-

perature Sensor” thermocouple or high speed drain tem-

perature wiring between the “Proximity/Temperature

Sensor” module and the MicroComputer Control Cen-

ter has been disconnected or has a poor electrical con-

nection.

IMPORTANT: Open thermocouple shutdowns would

typically indicate hardware or wiring defects and should

not result in any damage to the compressor high speed

thrust bearing. Therefore, a bearing inspection is not

required. However, due to the critical nature of these

circuits, anytime this shutdown occurs, a special re-

set procedure must be performed by a qualified ser-

vice technician before the chiller can be restarted.

This procedure is detailed in Service manual, Form

160.49-M3.

MON XX:XX AM – DC UNDERVOLTAGE

The “Proximity/Temperature Sensor” module becomes

unstable in operation when the +24VDC supply de-

creases to +17VDC. Therefore, the Micro Board moni-

tors the +24VDC supply and when it decreases to

+19VDC, it shuts down the chiller and displays this

message, preventing invalid “Proximity Sensor Safety”

or “High Speed Drain Temp” safety shutdowns. The

chiller will automatically restart when the voltage in-

creases to greater than +19.7 VDC.

MON XX:XX AM – AUX SAFETY SHUTDOWN

The system is shut down because an external device,

connected to digital input board TB1-31 (Auxiliary Safety

Shutdown Input), has initiated a system shutdown. This

input is a general purpose input that can be used to

annunciate a user-defined safety shutdown. To restart

chiller, press COMPRESSOR switch to STOP-RESET

position and then to START position.

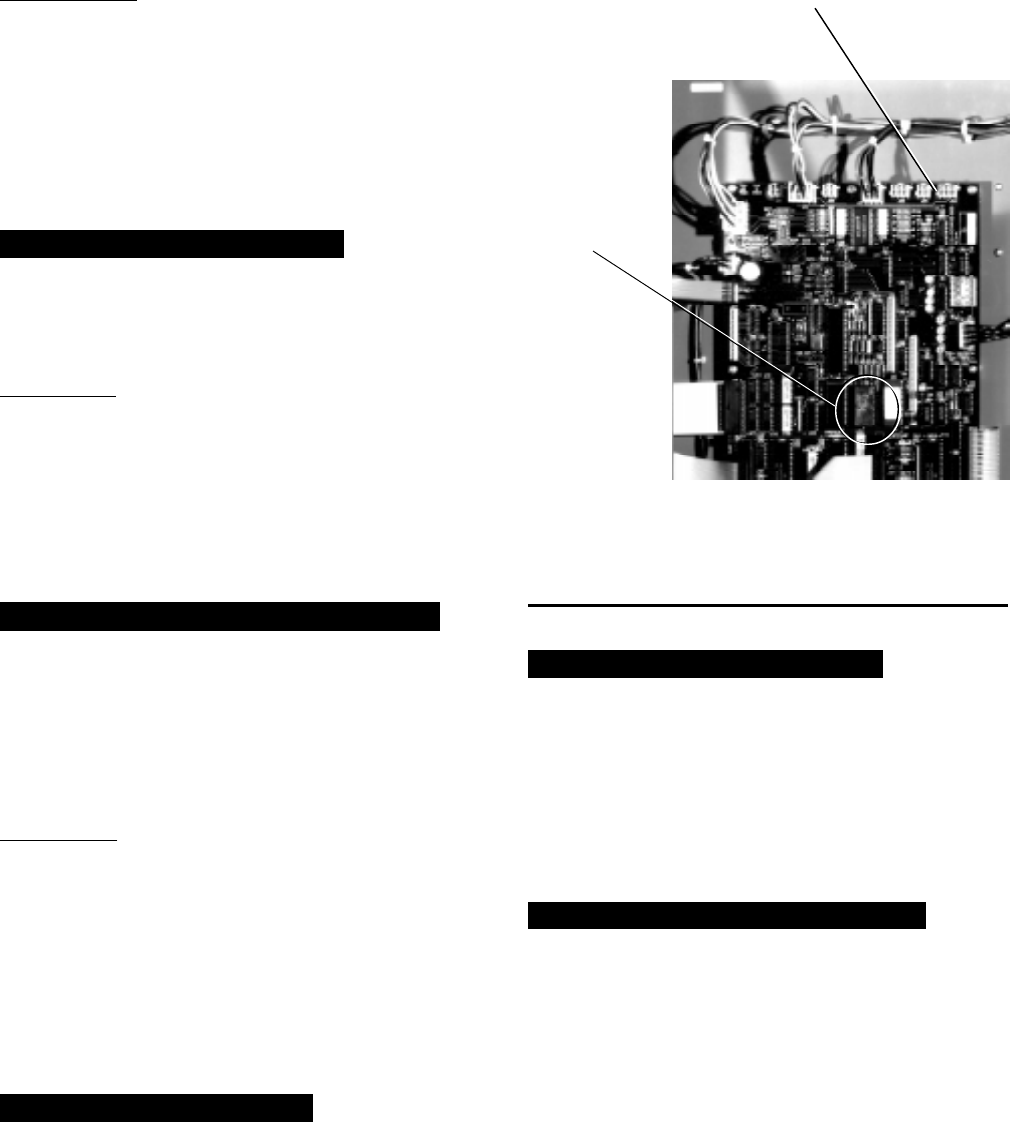

REPLACE RTC. U16 – REPROGRAM SETPOINTS

Indicates that the battery located inside the REAL-

TIME CLOCK IC chip (U16 on the Micro Board) is

defective. This battery provides back-up power to the

RTC memory (RAM) in the event of a utility AC power

failure. This assures the system setpoints will be main-

tained. If this message appears, the RTC IC chip (U16)

on the Micro Board must be replaced. If there had been

a power failure while this message is displayed, the

setpoints will have been lost and must be repro-

grammed. Order a replacement RTC IC chip (YORK

part number 031-00955-000) from the YORK Parts Dis-

tribution Center. With AC power removed from system,

locate RTC chip U16 on the Micro Board and remove

existing RTC chip from socket and discard. Observe

anti-static precautions and install new RTC chip in

socket. Assure proper IC orientation – orientation notch

must be UP. (Refer to Fig. 14.)

FIG. 14 – MICROCOMPUTER CONTROL CENTER

LOCATION OF REAL TIME CLOCK U16

RTC IC CHIP

24673A

MICRO BOARD

U16 RTC

IC CHIP

REAL

TIME

CLOCK