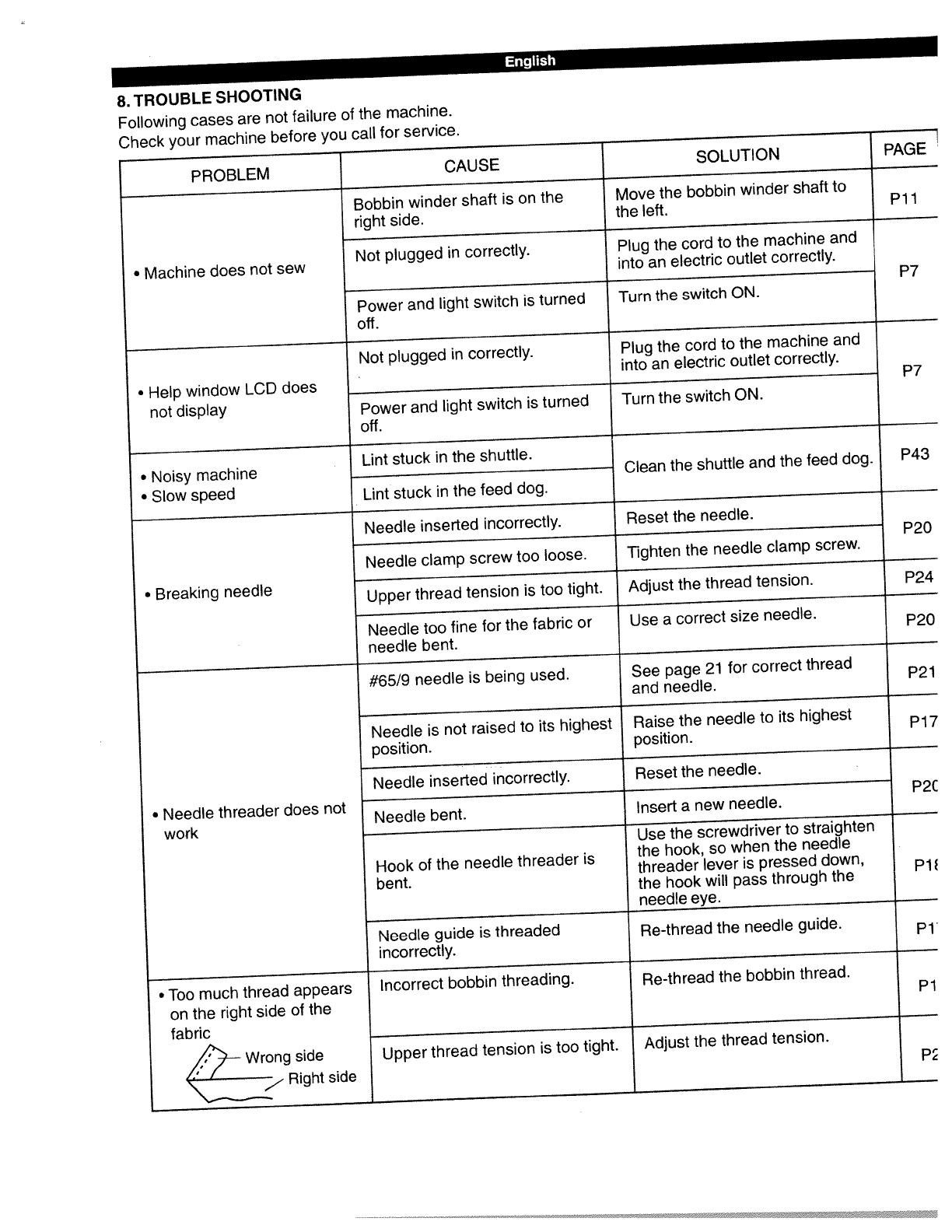

English

8.

TROUBLE

SHOOTING

Following

cases

are

not

failure

of

the

machine.

Check

your

machine

before

you

call

for

service.

Needle

guide

is

threaded

incorrectly.

PROBLEM

CAUSE

SOLUTION

PAGE

Bobbin

winder

shaft

is

on

the

Move

the

bobbin

winder

shaft

to

right

side.

the

left.

P1

1

•

Machine

does

not

sew

Not

plugged

in

correctly.

Plug

the

cord

to

the

machine

and

into

an

electric

outlet

correctly.

P7

Power

and

light

switch

is

turned

Turn

the

switch

ON.

off.

Not

plugged

in

correctly.

Plug

the

cord

to

the

machine

and

into

an

electric

outlet

correctly.

•

Help

window

LCD

does

P7

not

display

Power

and

light

switch

is

turned

Turn

the

switch

ON.

off.

Lint

stuck

in

the

shuttle.

•

Noisy

machine

Clean

the

shuttle

and

the

feed

dog.

P43

•

Slow

speed

Lint

stuck

in

the

feed

dog.

Needle

inserted

incorrectly.

Reset

the

needle.

P20

Needle

clamp

screw

too

loose.

Tighten

the

needle

clamp

screw.

•

Breaking

needle

Upper

thread

tension

is

too

tight.

Adjust

the

thread

tension.

P24

Needle

too

fine

for

the

fabric

or

Use

a

correct

size

needle.

needle

bent.

P20

#65/9

needle

is

being

used.

•

Needle

threader

does

not

work

See

page

21

for

correct

thread

and

needle.

P21

Needle

is

not

raised

to

its

highest

Raise

the

needle

to

its

highest

P17

position.

position.

Needle

inserted

incorrectly.

Reset

the

needle.

P2C

Needle

bent.

Insert

a

new

needle.

Use

the

screwdriver

to

straighten

Hook

of

the

needle

threader

is

the

hook,

so

when

the

needle

bent.

threader

lever

is

pressed

down,

the

hook

will

pass

through

the

needle

eye.

Re-thread

the

needle

guide.

•

Too

much

thread

appears

Incorrect

bobbin

threading.

Re-thread

the

bobbin

thread.

on

the

right

side

of

the

P1

fabric

,“

Wrong

side

Upper

thread

tension

is

too

tight.

Adjust

the

thread

tension.

-

Right

side

P