28

DRAINING

The heater must be drained if it is to be shut down and exposed

to freezing temperatures. Maintenance and service procedures

may also require draining the heater.

1. Turn off the heater electrical disconnect switch.

2. Close the cold water inlet valve to heater.

3. Open a nearby hot water faucet to vent the system.

4. Open the heater drain valve.

5. If the heater is being drained for an extended shutdown, it is

suggested the drain valve be left open this period.

• Follow FILLING instructions when restoring hot water service.

SEDIMENT REMOVAL

Waterborne impurities consist of the particles of soil and sand

which settle out and form a layer of sediment on the bottom of

the tank.

For convenience, sediment removal and lime scale removal should

be performed at the same time.

LIME SCALE REMOVAL

The amount of calcium carbonate (lime) released from water is

in direct proportion to water temperature and usage. The higher

the water temperature or water usage, the more lime deposits are

dropped out of the water. This is the lime scale which forms in

pipes, heaters and on cooking utensils.

Lime accumulation not only reduces the life of the equipment

but also reduces efciency of the heater and increases fuel

consumption.

The usage of water softening equipment greatly reduces the

hardness of the water. However, this equipment does not

always remove all of the hardness (lime). For this reason

it is recommended that a regular schedule for deliming be

maintained.

The depth of lime build-up should be measured periodically.

Heaters will have about 3” (76 mm) of lime build-up when the level

of lime has reached the bottom of the cleanout opening or about

1” of lime build-up if it has reached the drain valve opening. A

schedule for deliming should be set up; based on the amount of

time it would take for a 1” (25.4 mm) build-up of lime.

Example 1 – Initial inspection shows 1/2” (12.7 mm) of lime

accumulation. Therefore, the heater can be

delimed once a year.

Example 2 – Initial inspection shows 2” (50.8 mm) of lime

accumulation. Therefore, the heater should be

delimed every 3 months.

Sediment and lime scale removal may be accomplished through

the cleanout opening furnished on the heater, see FEATURES.

The heater must be drained. See DRAINING, before removing

cleanout cover on tank.

To dissolve and remove the more stubborn mineral deposits, State

UN•LIME

®

Professional delimer should be used.

State UN•LIME

®

Delimer is an easy to handle patented food grade

acid formulated specically for lime scale removal from all types

of water using equipment. Available in 1 gallon (part no. 4763)

and 5 gallon (part no. 4813) sizes. Hydrochloric base acids are

not recommended for use on glass-lined tanks.

State Form No. 4800 entitled “Why, When and How”, describes

tank cleaning methods and materials. UN•LIME

®

and the booklet

may be obtained through your State dealer or distributor.

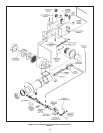

The cleanout opening is shown in Figure 9.

To clean heater through cleanout opening, proceed as follows:

1. Turn off water inlet valve, the heater electrical disconnect switch

and open drain valve.

2. Remove outer cover plate from lower side of heater jacket.

3. Remove cover from cleanout opening.

4. Remove lime, scale or sediment using care not to damage the

glass lining.

5. Inspect cleanout plate gasket; if new gasket is required, replace

with State part no. 99038.

6. Install cleanout plate. Be sure to draw plate up tight by

tightening screws securely.

7. Close drain valve, open water inlet line and turn on the burner

electrical disconnect switch.

8. Check for water leakage.

9. Replace outer jacket cover plate.

RELIEF VALVE

At least twice a year, the temperature and pressure relief valve

should be checked to ensure that it is in operating condition. To

check the relief valve, lift the lever at the end of the valve several

times. The valve should seat properly and operate freely.

CAUTION

BEFORE MANUALLY OPERATING A RELIEF VALVE, MAKE

SURE THAT A DRAIN LINE HAS BEEN ATTACHED TO THE

VALVE TO DIRECT THE DISCHARGE TO AN OPEN DRAIN.

FAILURE TO TAKE THIS PRECAUTION COULD MEAN

CONTACT WITH EXTREMELY HOT WATER, PASSING OUT OF

THE VALVE, DURING THIS CHECKING OPERATION.

If the temperature and pressure relief valve on the heater

discharges periodically or continuously, it may be due to thermal

expansion of water in a closed water supply system, or, it may be

due to faulty relief valve.

Thermal expansion is the normal response of water when it is

heated. In a closed system, thermal expansion will cause the

system pressure to build until the relief valve actuation pressure

is equaled. Then, the relief valve will open, allowing some water

to escape, slightly lowering the pressure.

Contact your water supplier or local plumbing inspector on how

to control this situation.

Two common corrections are listed in the CHECKLIST AND

SERVICE INFORMATION that appears later in this manual.