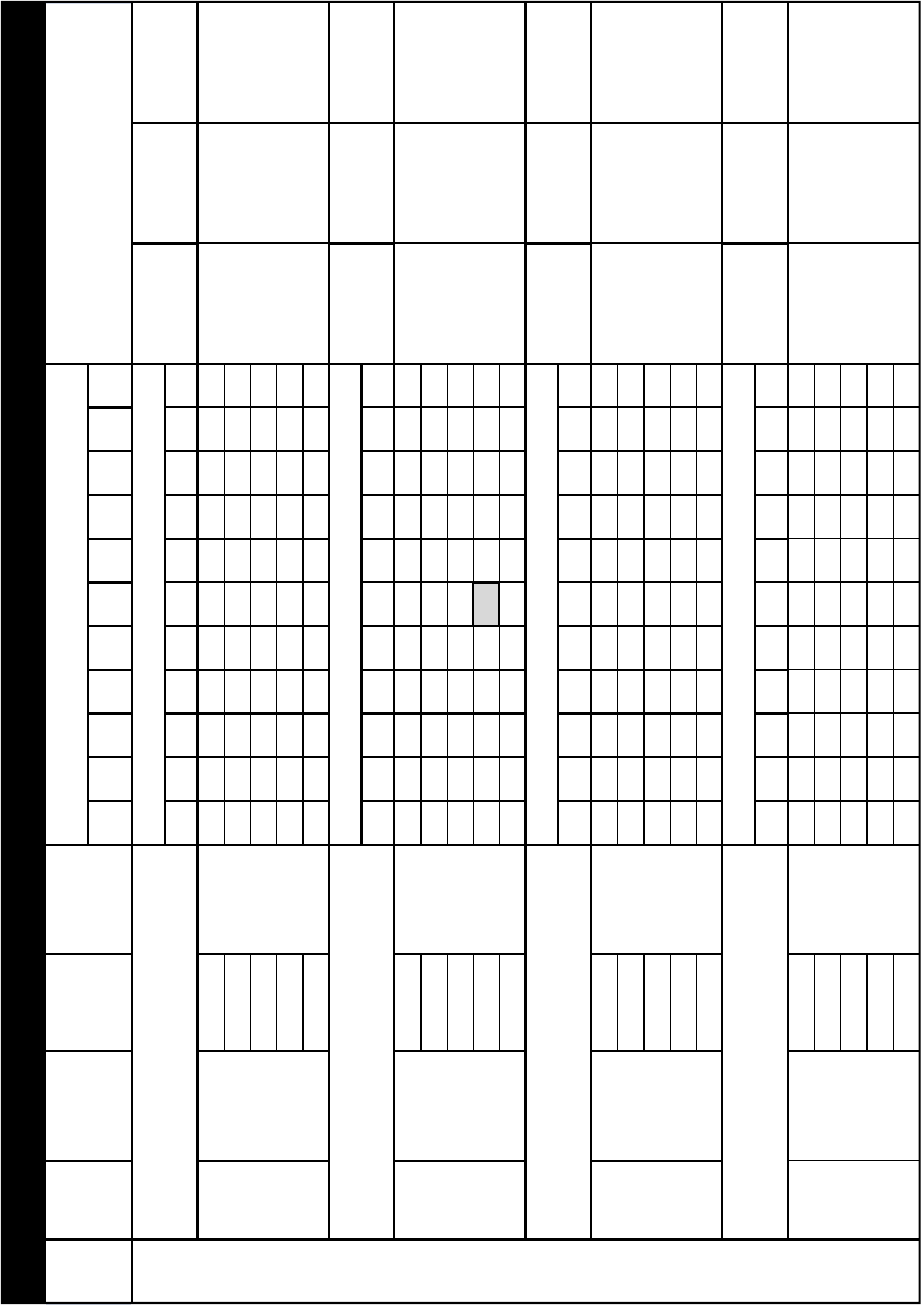

Rinnai Corporation Hydronic Furnace (37AHB) Manual 39

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

1934 1889 1857 1818 1784 1750 1715 1680 1568 1491 1377

120 61.4 60.0 59.0 57.8 56.7 55.6 54.5 53.4 49.8 47.4 43.7

130 71.4 69.7 68.6 67.1 65.9 64.6 63.3 62.0 57.9 55.0 50.8

140 80.9 79.0 77.7 76.0 74.6 73.2 71.7 70.3 65.6 62.4 57.6

150 92.7 90.5 89.0 87.1 85.5 83.9 82.2 80.5 75.1 71.4 66.0

160 104.4 102.0 100.2 98.1 96.3 94.5 92.6 90.7 84.6 80.5 74.3

1777 1732 1694 1650 1630 1592 1553 1517 1464 1441 1361

120 59.5 58.0 56.7 55.2 54.6 53.3 52.0 50.8 49.0 48.3 45.6

130 68.9 67.1 65.6 63.9 63.2 61.7 60.2 58.8 56.7 55.8 52.7

140 79.1 77.1 75.4 73.5 72.6 70.9 69.1 67.5 65.2 64.2 60.6

150 90.4 88.1 86.2 84.0 82.9 81.0 79.0 77.2 74.5 73.3 69.3

160 101.4 98.9 96.7 94.2 93.0 90.9 88.6 86.6 83.6 82.2 77.7

1573 1530 1490 1448 1417 1372 1327 1293 1253 1221 1175

120 57.1 55.6 54.1 52.6 51.5 49.8 48.2 47.0 45.5 44.3 42.7

130 66.0 64.2 62.5 60.8 59.5 57.6 55.7 54.3 52.6 51.3 49.3

140 76.3 74.3 72.3 70.3 68.8 66.6 64.4 62.8 60.8 59.3 57.0

150 87.6 85.2 83.0 80.7 78.9 76.4 73.9 72.0 69.8 68.0 65.4

160 97.9 95.2 92.7 90.1 88.2 85.4 82.6 80.5 78.0 76.0 73.1

1400 1351 1317 1275 1225 1183 1134 1095 1053 1011 951

120 54.4 52.5 51.2 49.5 47.6 46.0 44.1 42.5 40.9 39.3 37.0

130 63.2 61.0 59.5 57.6 55.3 53.4 51.2 49.5 47.6 45.7 42.9

140 73.1 70.5 68.7 66.5 63.9 61.7 59.2 57.2 55.0 52.8 49.6

150 85.0 82.0 80.0 77.4 74.4 71.8 68.8 66.5 63.9 61.4 57.7

160 93.7 90.4 88.2 85.3 82.0 79.2 75.9 73.3 70.5 67.7 63.7

NET

HEATING

CAPACITY

(MBH)

27 32 40

40

AHB90 + RC80HPi(e)

AIRFLOW (CFM)

TAP 3

(ML)

3.5

NET

HEATING

CAPACITY

(MBH)

40

Minimum Legs @

60 CFM/Leg

27 32 40

32

Maximum legs @

40 CFM/Leg

Optimal Legs @

50 CFM/Leg

Maximum legs @

40 CFM/Leg

AHB90 + RC80HPi(e)

AIRFLOW (CFM)

TAP 2

(MH)

4.0

NET

HEATING

CAPACITY

(MBH)

27

37AHB09016KA5 + REU-KA2530FFUD(WD)-US

AHB90 + RC80HPi(e)

AIRFLOW (CFM)

TAP 1

(H)

5.0

NET

HEATING

CAPACITY

(MBH)

AHB90 + RC80HPi(e)

AIRFLOW (CFM)

TAP 4

(L)

3.0

UNIT

SIZE

ECM

SPEED

TAP

SUPPORTS

COOLING CAP.

RANGE (TONS)

EWT (

O

F)

NOMINAL

HEATING

CAPACITY

External Static Pressure (ESP)

Number of 3" Diameter Branch Legs applicable to High

Velocity Systems Only. Used only if methods other

than Table 3 is used to determine duct sizes.

TABLE 5.7: AIR DELIVERY AND PERFORMANCE DATA (BOTTOM OR SIDE RETURN w/ FACTORY SUPPLIED FILTER)

Minimum Legs @

60 CFM/Leg

Optimal Legs @

50 CFM/Leg

Maximum legs @

40 CFM/Leg

Minimum Legs @

60 CFM/Leg

Optimal Legs @

50 CFM/Leg

Maximum legs @

40 CFM/Leg

Minimum Legs @

60 CFM/Leg

Optimal Legs @

50 CFM/Leg

27 32

NOTES:

1. EWT - Entering Water Temperature (F).

2. CFM - Airflow in (Cubic Feet per Minute).

3. Legs - 3 inch diameter flexible ducts to diffusers.

4. 1 MBH = 1000 BTU/H.

5. Shaded box represents rating point; refer to wiring diagram for factory set speed taps.

6. Number of 3” diameter legs specified in table above is for rating point only (i.e. at External Static Pressure of 0.5

in. wc. and speed TAP3, TAP1, TAP2 , TAP2 for AHB45, AHB60, AHB75, AHB90 respectively). Final leg count is

to be determined by the installing contractor and is to be based on the following formula:

NUMBER OF LEGS = TOTAL AVAILABLE CFM

(AT THE SPECIFIC ESP)

/ DESIRED CFM per LEG

(40, 50, or 60 CFM)

Example: Given the design point for AHB045 of 0.8 ESP, Low fan speed (Tap5). From table 5.0, available CFM is

569 and the desired CFM per leg is 50 CFM. Therefore, Number of Legs = 569/50 = 11.38 rounded down to 11.

TBD

See Note 6.

TBD

See Note 6.

TBD

See Note 6.

TBD

See Note 6.

TBD

See Note 6.

TBD

See Note 6.

TBD

See Note 6.

TBD

See Note 6.

TBD

See Note 6.

in. W.C.