16

Rinnai Corporation Hydronic Furnace (37AHB) Manual

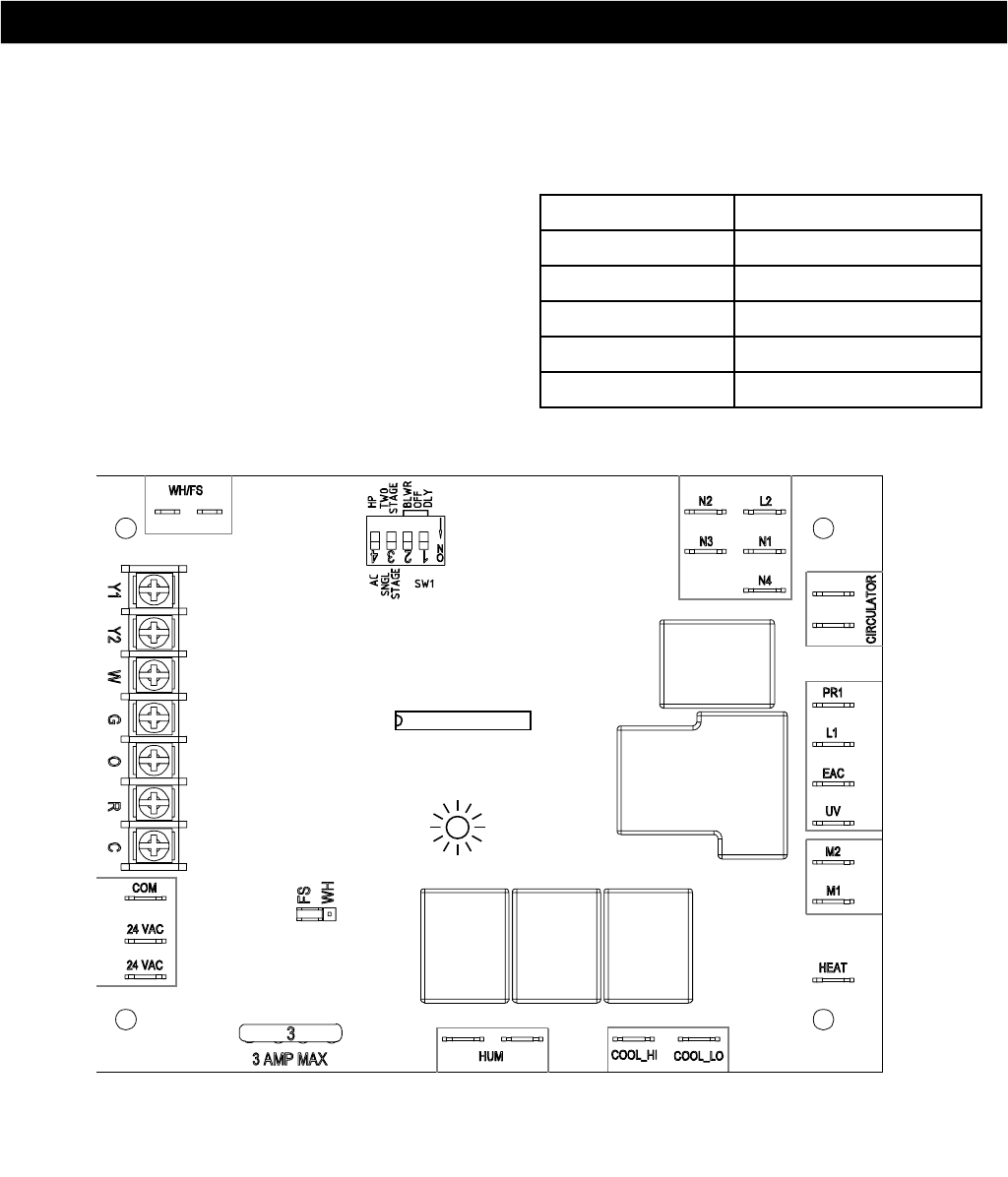

FLOW SENSOR

CONNECTIONS

SW1 SET-UP SWITCH

AND HEATING BLOW

OFF DELAY

24 V THERMOSTAT

TERMINALS

TRANSFORMER 24 V

CONNECTIONS

P3

P4

P1

3AMP FUSE

OPERATING MODE

JUMPER (SHUNT)

STATUS LED LIGHT

115 VAC (L2)

NEUTRAL

CONNECTIONS

PUMP

CONNECTIONS

115 VAC (L1) LINE

VOLTAGE

CONNECTION

FAN

PARK

FAN

CONNECTION

HEATING

FAN

CONNECTION

COOLING

HUMIDIFIER CONNECTIONS

(DRY CONTACT) 24 VAC OR

115 VAC

FLASH UPGRADE

CONNECTION

(FACTORY ONLY)

u1

AN1

Installation

Figure 14: Hydronic Furnace Control Board

P7

Notes:

1. For proper operation of an open loop system with the flow sensor refer to Figures 11 and 14; Note that the

jumper (shunt) position on the PCB “point P7” MUST be in the FS position.

2. When changing the shunt position ensure that the unit’s power is turned off.

Wire Gauge Maximum Distance (feet)

20 gauge 45

18 gauge 60

16 gauge 100

14 gauge 160

12 gauge 250

System Low Voltage Wiring Diagrams

NOTE: Local codes may require thermostat wiring to

be routed through conduit or raceways. In such

instances splices can be made inside the Hydronic

Furnace. All wiring must be NEC Class l and must be

separated from incoming power leads.

Provide field supplied disconnect. Refer to Table 4

(Specifications) for maximum fuse or circuit breaker

sizes.

Transformer is factory wired for 115v operation. (See

Figures 27 through 29.)

The secondary circuit of the transformer is protected

by a 3-amp fuse mounted on the printed-circuit board.

IMPORTANT: Where possible, use a Rinnai factory

authorized thermostat with the 37AHB series Hydronic

Furnaces. If a thermostat other than specified is used,

refer to the manufacturer’s installation instructions for

further details.