Rinnai Corporation Hydronic Furnace (37AHB) Manual 21

Installation

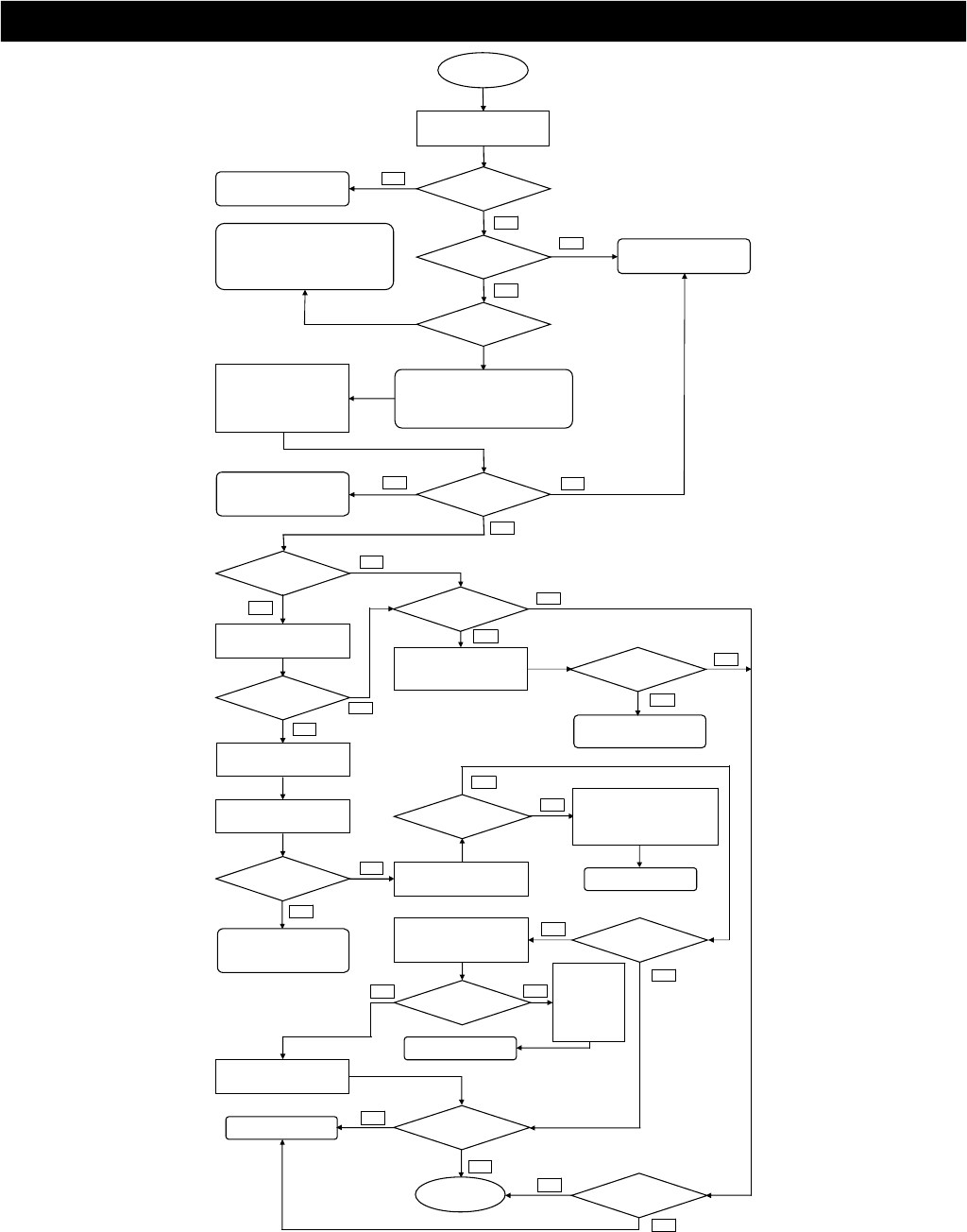

Figure 21: Blower System 115V Troubleshooting - Flow Sensor (FS) Configuration

()

NO

STEADY 'LED'

FLASH

NO

WITH DOOR SWITCH CLOSED

(SET SYSTEM IN HEATING

MODE; CALL FOR HEAT)

START

IS 'LED' ON

RAPID FLASH - PUMP NOT ENERGIZED -

CAUSES:

1. SEARCH MODE (INSUFFICIENT FLOW);

2. NO POWER TO PUMP ;

3. NO POWER TO FLOW SENSOR

GO TO RHF START-UP & 'LED'

TROUBLESHOOTING

NO

YES

STEADY 'LED'

FLASH

'LED' FLASH

CODE

TO ISOLATE CAUSE: ENSURE

THAT SYSTEM IS PURGED AND

ALL FAUCETS AND OTHER

WATER CONSUMING

EQUIPMENT IS OFF (FLOW TO

RHF SHOULD BE ≥ 1 GPM)

YES

PULSING FLASH WITH PUMP AND FAN

ENERGIZED (associated with contactor

clicking sound) - WRONG SHUNT POSITION

FOR OPERATING MODE - REFER TO

FIG.14; CHANGE SHUNT POSITION AND

RETUR

N

T

O

START

NORMAL OPERATION OR

STAND-BY MODE (AWAITING

THERMOSTAT CALL)

YES

GO TO CIRCULATING PUMP

115 v TROUBLESHOOTING

YES

FINISH

YES

NO

CHECK FOR LOOSE OR BROKEN

WIRES

CHECK VOLTS ACROSS 'FAN'

CONNECTIONS ON PCB ('COOL-

HI' AND 'N4')

VAC = 115V +/-

NO

YES

PROBLEM(S) WITH 24V TO PCB

- GO TO 24V

TROUBLESHOOTING CHART

FAN AMP DRAW

NORMAL

NO

CHECK CAPACITOR; IF

DEFECTIVE REPLACE

COMPONENT AND RE-CHECK

AMP DRAW

YES

RETURN TO START

NO

FAN AMP DRAW

NORMAL

CHECK FAN

MOTOR; IF

DEFECTIVE

REPLACE

COMPONENT

AND RE-CHECK

AMP DRAW

NO

CONNECT FAN DIRECTLY TO

115 VAC POWER SUPPLY

FAN MOTOR

ENERGIZED

(1) RECTIFY WIRING PROBLEM(S)

(2) CHECK MOTOR AND

CAPACITOR; IF DEFECTIVE,

REPLACE FAULTY COMPONENT(S)

RETURN TO START

NO

YES

YES

YES

CONTACT TECH.

SUPPORT

RECONNECT WIRES AND

CONFIRM THAT WIRING IS AS

PER WIRING DIAGRAMS

SYSTEM

WORKING

SYSTEM

WORKING

ADJUST THERMOSTAT SET

TEMPERATURE HIGHER THAN

ROOM TEMPERATURE

FAN

ENERGIZED

YES

NO

CHECK CAPACITOR; IF

DEFECTIVE, REPLACE

COMPONENT AND RE-CHECK

AMP DRAW

FAN AMP DRAW

NORMAL

YES

NO

CHECK FAN MOTOR; IF

DEFECTIVE REPLACE

CO

MP

O

NENT

FAN

ENERGIZED

YES

NO

FAN AMP DRAW

NORMAL

YES

NO