Page 34

433-1390D

September 7, 2007

R

7100FP EPA Woodburning Fireplace

INSTALLATION

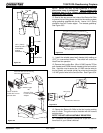

1. Remove the knockout or cover plate from the top of the

fi replace and discard it. See Figure 34.1.

2. Cut a 3 in. (76mm) hole in the insulation board as per the

dimensions shown in Figure 34.1.

Adapter

Mounting

Plate

Starter Pipe

Knockout

Cut a 3 in. (76mm) hole

in insulation board

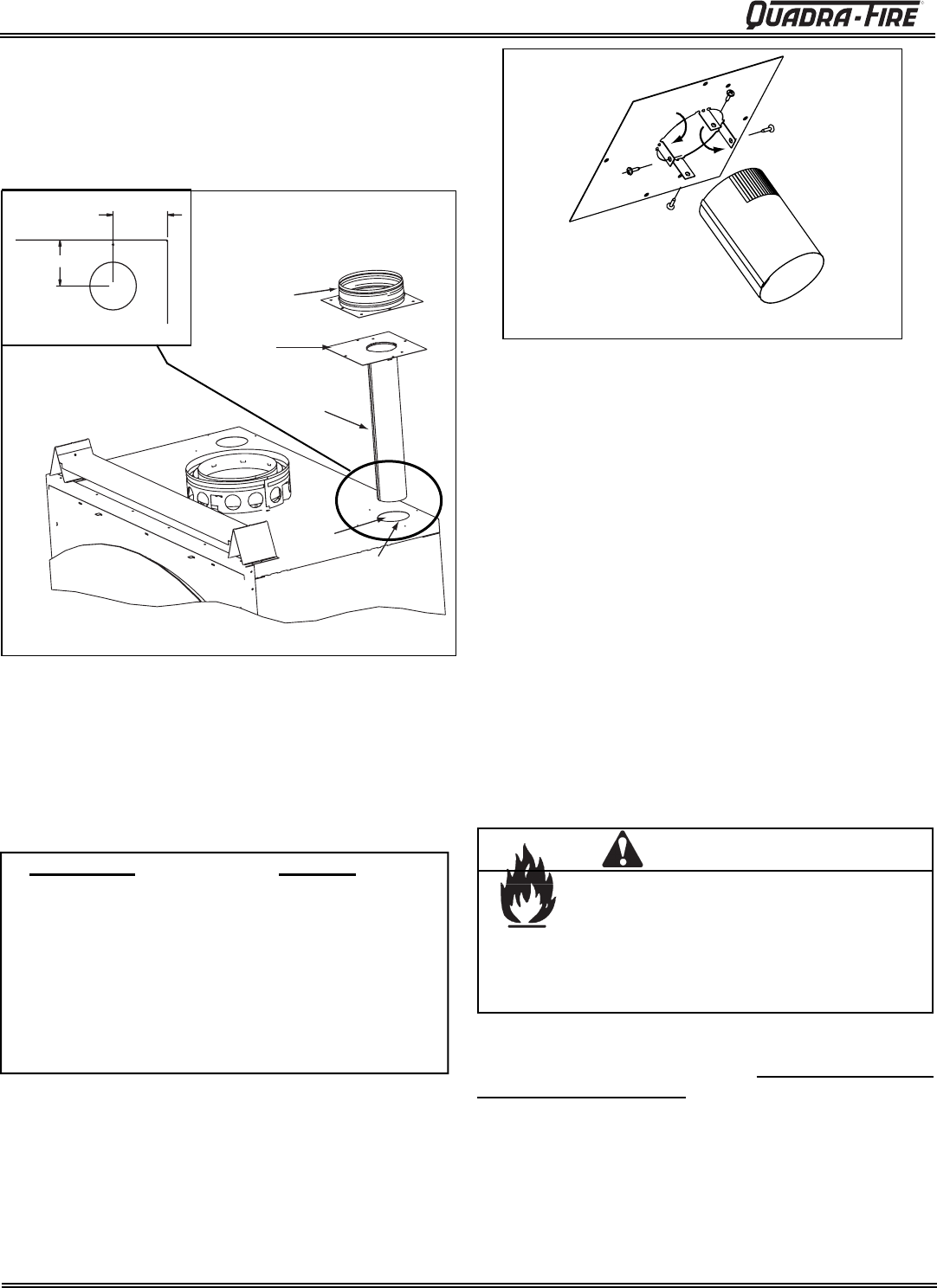

5. On the Mounting Plate, hand bend the tabs downward.

Slide the tabs over the outside of the starter pipe. Secure

with 4 sheet metal screws included in fasteners package.

Figure 34.3.

3-13/16 in.

(97mm)

3-1/8 in. (79mm)

C

L

Run Length Cut Pipe

20 - 40 ft (6-12m) 2 in. (51mm)*

*A minimum of 2 in. (51mm) pipe must be used to

cover the raw insulation to prevent it tfrom blow-

ing out through the Return Air Grille.

10 - 20 ft (3 - 6m) 8 in. (203mm)

3 - 10 ft (1 - 3m) No cut needed**

**

Use full 16 in. (406mm) as supplied

3. Determine the necessary length of starter pipe from the

following table and cut as required. See Figure 34.2.

4. The starter pipe is shipped fl at. After cutting to the required

length, manually roll the pipe together and snap lock into

place. NOTE: It is important the pipe length be adhered

to or it will affect the performance of your fi replace.

6. Slide the starter pipe into the fi replace, matching the holes

in the plate to the holes in the fi replace.

7. Place the Adapter on the Mounting Plate lining up holes.

Using the 4 sheet metal screws included in the kit, secure

the Adapter and Mounting Plate into fi replace. After secur-

ing to the fi replace, tape down the Adapter edges to the top

of the fi replace with aluminum tape to prevent leakage.

8. Determine the location for the air register and fan housing

assembly. Cut a 7-5/8 in. x 13-5/8 in. (143 x 346mm) hole

between framing members (wall studs or fl oor joists). The

brackets can be rotated 180° and mounted to the back side

of the 2 x 4 if necessary. See Figure 35.2 on page 35.

NOTE: The fan and electrical connections must be

accessible for servicing per local code requirements.

NOTE: If the fan housing is installed in a 2 x 4 wall, the

front of the housing will protrude approximately 1/4 in.

(6mm) from the fi nished wall. See Figure 35.1 on page

35.

9. Attach enough 6 in. (152mm) B-Vent as required for

your installation to the fan housing. A maximum of (4) 90°

elbows is recommended. Securely twist lock the B-Vent

to the Adapter.

Also screw the B-Vent to the outlet box on the fan housing.

See Figure 35.2 on page 35.

Support duct at intervals of no

greater than 4 ft (1 m) as required by local code.

Figure 34.1

Figure 34.2

Figure 34.3

Fire Risk

Comply with all minimum clearances speci-

fi ed.

• A minimum 1/2 in. (13mm) air clearance

must be maintained at the back and 1

in. (25mm) to the sides of the fi replace

assembly.

WARNING