27

W415-0788 / A / 09.22.09

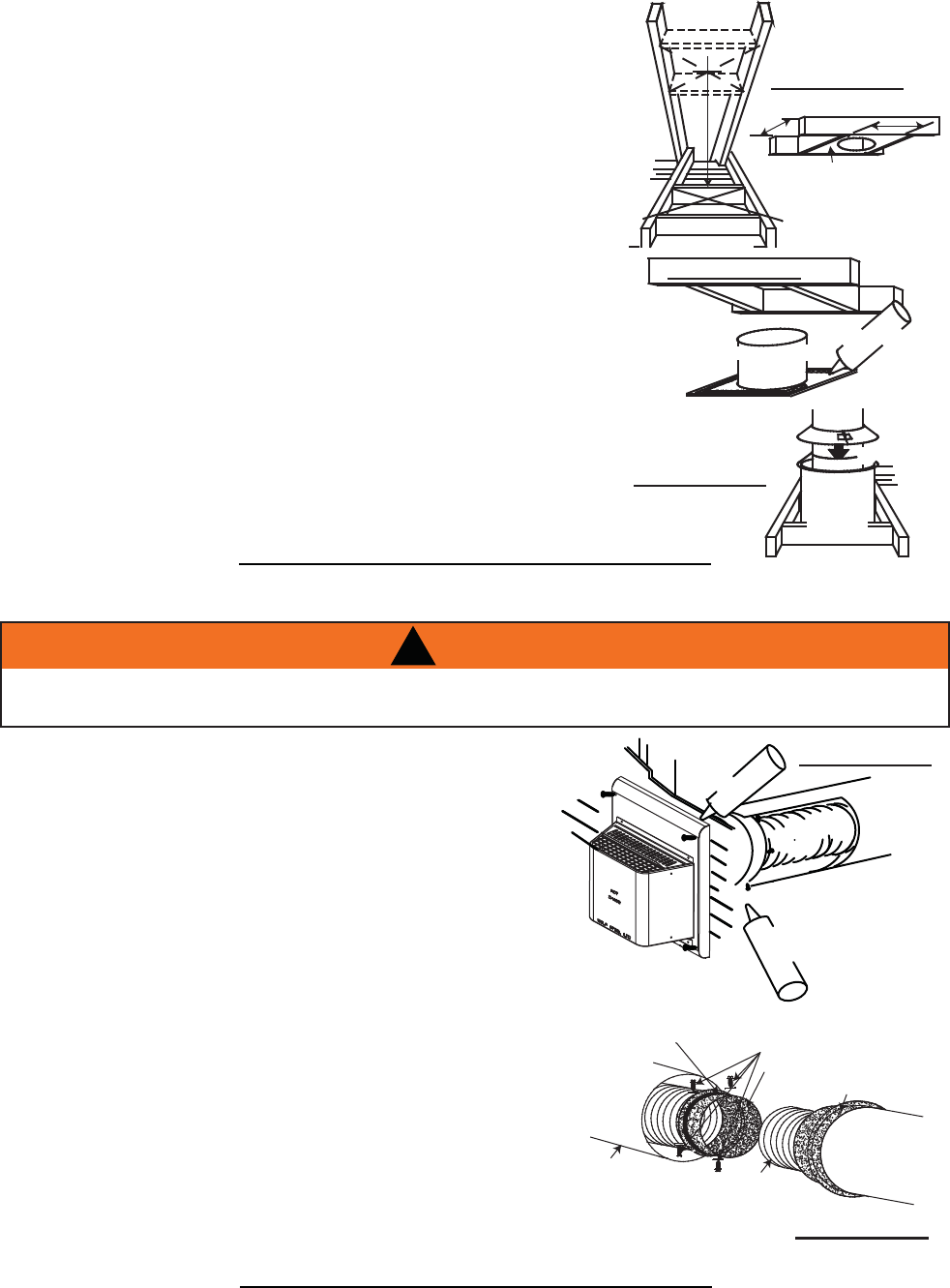

5.2.3 HORIZONTAL AIR TERMINAL INSTALLATION - MODEL GDS60

A

. Stretch the inner fl ex pipe to the required length taking

into account the additional length needed for the

fi nished wall surface. Slip the vent pipe a minimum of 2”

over the inner sleeve of the air terminal and secure with

3 #8 screws. Apply a heavy bead of the high temperature

sealant W573-0007 Mill Pac (not supplied).

B. Using the outer rigid pipe, slide over the outer combustion air

sleeve of the air terminal and secure with 3 #8 screws. Seal

using high temperature sealant W573-0002 (not supplied).

C. Insert the vent pipes through the fi restop maintaining the required clearance to

combustibles. Holding the air terminal (lettering in an upright,

readable position), secure to the exterior wall and make

weather tight by sealing with caulking (not supplied).

D. If more vent pipe needs to be used to reach the fi replace,

couple them together as illustrated. The vent system must be

supported approximately every 3 feet for both vertical and

horizontal runs. Use noncombustible strapping to maintain

the minimum clearance to combustibles.

The air terminal mounting plate may be recessed into the exterior wall or siding no greater than the depth of its

return fl ange.

23.7

SCREWS

#10x2"

SEALANT

HIGH TEMP

2" OVERLAP

PIPE

4"FLEX

CAULKING

PIPE

7" RIGID

#8 X 1/2” SELF DRILLING

SCREWS & WASHERS

INNER COUPLER

OUTER COUPLER

HI-TEMP

SEALANT

OUTER

RIGID PIPE

INNER

FLEX PIPE

OUTER

RIGID PIPE

5.2.2 VERTICAL INSTALLATION

This application occurs when venting through a roof. Installation kits for

various roof pitches are available from your authorized dealer / distributor. See

accessories to order specifi c kits required.

A. Determine the air terminal location, cut and frame a square opening as

illustrated in the ceiling and the roof to provide the minimum 1“ clearance

between the vent pipe and any combustible material. Try to center the vent

pipe location midway between two joists to prevent having to cut them. Use

a plumb bob to line up the center of the openings. A vent pipe shield will

prevent any materials such as insulation, from fi lling up the 1” air space

around the pipe. Nail headers between the joist for extra support.

B. Apply a bead of caulking (not supplied) to the framework or to the Wolf

Steel vent pipe shield plate or equivalent (in the case of a fi nished ceiling),

and secure over the opening in the ceiling. A fi restop must be placed on the

bottom of each framed opening in a roof or ceiling that the venting system passes

through. Apply a bead of caulking all around and place a fi restop spacer over

the vent shield to restrict cold air from being drawn into the room or around the

fi replace. Ensure that both spacer and shield maintain the required clearance to

combustibles. Once the vent pipe is installed in its fi nal position, apply sealant

between the pipe and the fi restop assembly.

C. In the attic, slide the vent pipe collar down to cover up the open end of the shield and tighten.

This will prevent any materials, such as insulation, from fi lling up the 1” air space around the

pipe.

21.1

CAULKING

VENT PIPE

SHIELD

FIRESTOP

UNDERSIDE OF

JOIST

VENT

PIPE

COLLAR

VENT

PIPE

SHIELD

TERMINALS MUST NOT BE RECESSED INTO A WALL OR SIDING MORE THAN THE DEPTH OF THE

RETURN FLANGE OF THE MOUNTING PLATE.

!

WARNING

FIGURE 5.2.2a

FIGURE 5.2.2b

FIGURE 5.2.2c

FIGURE 5.2.3a

FIGURE 5.2.3d