62

Forced defrost Start

Normal

Normal

—

When compressor is

working in heating

operation. +

Abnormal history clear

No function

Self-diagnosis

(Indoor unit selection)

Indicating a particular

self-diagnosis

Clear

—

off or operating

—

Test run Operating OFF

Under suspension

Test run mode setting

Heating Cooling

Indoor No.1

Indoor No.4

Indoor No.7

Indoor No.2

Indoor No.5

Indoor No.8

Indoor No.3

Indoor No.6

1

2

3

4

5

6

1

2

ON OFF

No.

Function Effective timing

Action by the switch operation

Switch

SW1

Dip

switch

SW4

Type of

Switch

OC

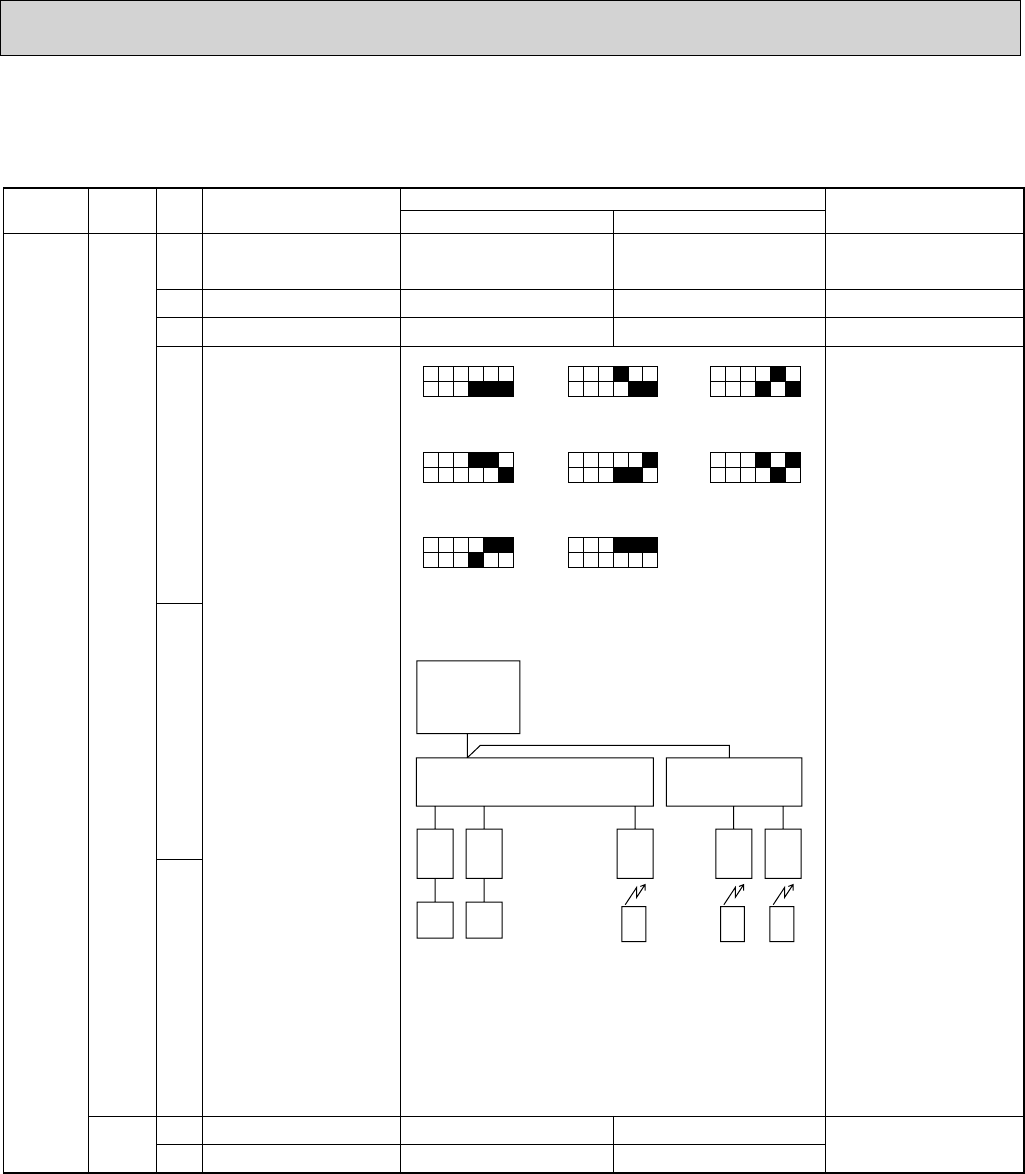

<Example>

ABCDEABC

IC

RC

IC IC

RC

Indoor

No.1

Indoor

No.2

Indoor

No.3

Indoor

No.4

Indoor

No.5

R

C

IC

R

C

IC

R

C

BC#1 (5- branch type)

BC#2

(3- branch type)

BC#1 : branch box controller unit Number 1

1 blinking LED2 (branch box controller board)

BC#2 : branch box controller unit Number 2

2 blinking LED2 (branch box controller board)

1

ON

23456

1

ON

23456

1

ON

23456

1

ON

23456

1

ON

23456

1

ON

23456

1

ON

23456

1

ON

23456

8-8. FUNCTION OF SWITCHES, CONNECTORS AND JUMPERS

(1) Function of switches

MXZ-8B48NA The black square (■) indicates a switch position.

Forced defrost should be done as follows.

1 Change the DIP SW1-1 on the outdoor controller board from OFF to ON.

2 Forced defrost will start by the above operation 1 if these conditions written below are satisfied.

• Heat mode setting

• 10 minutes have passed since compressor started operating or previous forced defrost finished.

• Pipe temperature is less than or equal to 8: [46 °F].

3 Forced defrost will finish if certain conditions are satisfied.

w Forced defrost can be done if above conditions are satisfied when DIP SW1-1 is changed from OFF to ON.

After DIP SW1-1 is changed from OFF to ON, there is no problem if DIP SW1-1 is left ON or changed to OFF again. This

depends on the service conditions.