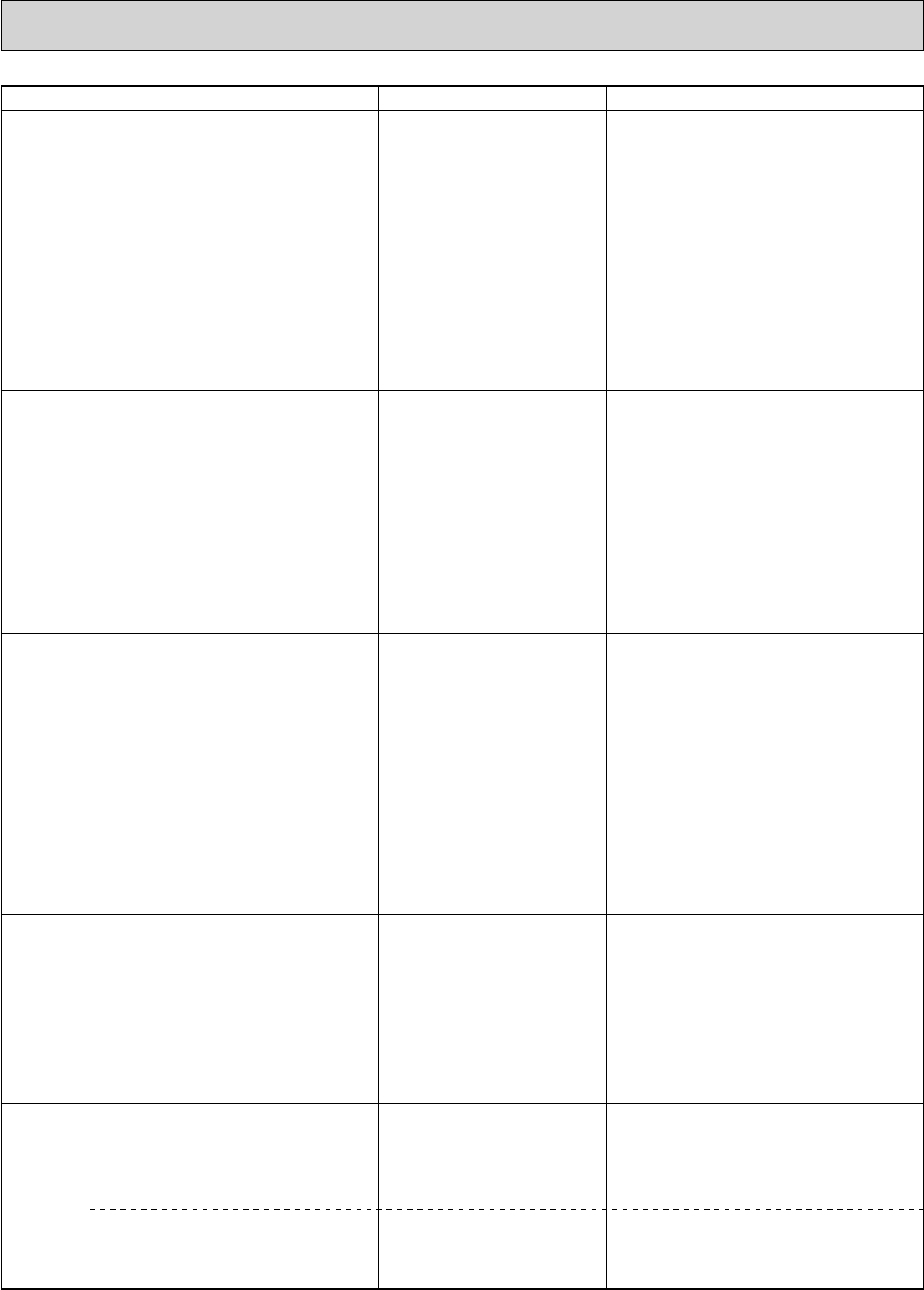

47

Error Code

Abnormal point and detection method

Judgment and action

Case

UF

(4100)

Compressor overcurrent interruption

(When compressor locked)

Abnormal if overcurrent of DC bus or

compressor is detected within 30 seconds

after compressor starts operating.

1 Stop valve is closed.

2 Decrease of power supply

voltage

3 Looseness, disconnection or

converse of compressor wiring

connection

4 Defective compressor

5 Defective outdoor power board

1 Open stop valve.

2 Check facility of power supply.

3 Correct the wiring (U·V·W phase) to

compressor.

Refer to 8-7.

4 Check compressor.

Refer to 8-6.

5 Replace outdoor power circuit board.

U9

(4220)

Overvoltage or voltage shortage and

abnormal synchronous signal to main

circuit

Abnormal if any of followings are detected

during compressor operation;

• Decrease of DC bus voltage to 310V

• Instantaneous decrease of DC bus voltage

to 200V

• Increase of DC bus voltage to 400V

• Decrease of input current of outdoor unit

to 0.5A only if operation frequency is more

than or equal to 40Hz or compressor

current is more than or equal to 5A.

1 Decrease of power supply voltage

2 Disconnection of compressor

wiring

3 Defective 52C

4 Disconnection or loose connec-

tion of CNAF

5 Defective 52C drive circuit of

outdoor controller circuit board

6 Disconnection or loose

connection of CN2 on the

outdoor power circuit board

1 Check the facility of power supply.

2 Correct the wiring (U·V·W phase) to com-

pressor. Refer to 8-7.

3 Replace power circuit board.

4 Check CNAF wiring.

5 Replace outdoor controller circuit board.

(12V DC output)

6 Check CN2 wiring on the outdoor power

circuit board.

Refer to 8-7.

U7

(1520)

(1) Too low superheat due to low dis-

charge temperature

Abnormal if discharge superheat is con-

tinuously detected –15: [-27°F] or less

even though linear expansion valve has

minimum open pulse after compressor

starts operating for 10 minutes.

(2)

Erroneous connection of refrigerant

pipes or the connecting wires

Consider the stopping indoor unit abnormal

if condenser/evaporator temperature ther-

mistor (TH5 or RT12) detects –5: [23°F]

or below continuously for 5 minutes during

a compressor’s operation in cooling mode.

1 Disconnection or loose

connection of discharge

temperature thermistor. (TH4)

2 Defective holder of discharge

temperature thermistor

1Failure in piping / wiring

2Pipe (liquid) is clogged or

crushed.

12 Check the installation conditions of

discharge temperature thermistor (TH4).

1Check piping / wiring between branch box

and indoor unit.

Refer to “Test run (Using remote controller)”.)

2Check the pipe for refrigerant and change the

wrong parts.

U8

(4400)

Outdoor fan motor

The outdoor fan motor is considered to be

abnormal if the rotational frequency of fan

motor is abnormal when detected during

operation.

Fan motor rotational frequency is abnormal

if;

• 100 rpm or below detected continuously

for 15 seconds at 26:

[79°F]

or more

outside air temperature

• 50 rpm or below or 1500 rpm or more

detected continuously for 1 minute.

1Failure in the operation of

the DC fan motor

2Failure in the outdoor circuit

controller board

1Check or replace the DC fan motor.

2Check the voltage of the outdoor circuit

controller board during operation.

3Replace the outdoor circuit controller

board. (when the failure is still indicated

even after performing the remedy 1

above.)

UH

(5300)

Current sensor error

Abnormal if current sensor detects –1.5A

to 1.5A during compressor operation. (This

error is ignored in case of test run mode.)

1 Disconnection of compressor

wiring

2 Defective circuit of current

sensor on outdoor power

circuit board

1 Correct the wiring (U·V·W phase) to com-

pressor. Refer to 8-7.

2 Replace outdoor power circuit board.

Abnormal if input current exceeds 38 A or

34A continuously 10 seconds. (Current sen-

sor on noise filter board detects input current)

1Decrease of power supply volt-

age

1Check the facility of power supply.