Page 46

506586−01 10/10

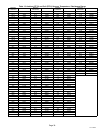

Table 16. Fan Motor Control RPM, LED Code and DC Voltage Output

Model LED Code*

CFM Profile Pin Select ECM1/Y1

4 3 2 1 RPM (J2) DC Volt

XP17−024 5 OFF ON ON ON 400 12.7

XP17−030 6 OFF ON ON OFF 450 14.3

XP17−036, −042 8 OFF OFF ON ON 600 19.2

XP17−048, −060 9 OFF OFF OFF ON 675 21.6

* LED Code indicates fan motor control LED flash sequence. For example, LED Code 9 indicates 9 slow flashes and pause.

Table 17. Fan Motor Control Error/Fault LED Codes

Unit Status Motor Control LED Possible Cause

Mismatched RPM

Fast flash with no

pause

Internal feedback,

PWM does not

match target

CRC Failure Constant ON.

Microcontroller CRC

failure

Table 18. 19. Fan Motor Control Stage LED Indicator

Codes

Unit Status Unit Status

Fan Motor Control

LED

One Stage

Operation

Low Stage Ċ

ECM1/Y1 ONLY

One slow flash, then

short pause.

Table 20. Fan Motor Control Flash and Pause

Durations

Flash or Pause State Duration

Flash Flash Three flashes per second

Slow Flash One flash per second

Short Pause Two seconds of OFF time

Long Pause Five seconds of OFF time

Testing

Use the following subsections to verify and test the fan

motor control (A177).

Verifying Jumper Settings (J2)

The unit is shipped from the factory with the default fan

motor speed setting (in RPMs) required for each specific

model. Use the table 16 verify that jumpers are set

correctly for the specific unit.

Verifying LED Status Codes

During start up, the fan motor control (A177) LED

will display any error conditions. If error conditions

exist then no other codes will display. If no error

conditions are present, then the stage status and

and RPM indicator are displayed. Fan motor speeds

are not adjustable for a single stage outdoor unit (see

table 16).

Verifying Correct DC Output Voltage (J2)

The following three methods can be used to determine

whether the fan motor (B4) is operating at the correct

RPMs based on unit size.

1. Use the information provided in table 16 to verify that

all four jumper terminals are set correctly for the

specific size unit.

2. Verify LED RPM indicator is displaying the correct

flash sequence for the applicable size unit (see table

18).

3. Test DC voltage output on the fan motor control’s J2

terminals (see figure 34) while under full load and

verify the voltage read to the voltage listed in table 16

for the applicable size unit.

4. If no voltage is detected at the J2 terminals, verify

there is a Y1 demand at the thermostat and applicable

voltages detected all fan motor control (A177) voltage

inputs, see table 21.

If there is a demand, proceed to the next section for further

testing.

Verifying Correct Input Voltage (ECM/Y1, ECM/Y2,

ECM C and EXT ECM/R)

Using a voltmeter, check voltages on the following fan

motor control inputs using table 21. Voltage will only be

present during a thermostat demand. See figure 35 for test

example.

If correct voltages are detected at applicable inputs during

a demand, and no voltage is present at the J2 terminals,

then fan motor control should be replaced.

Table 21. Fan Motor Control Voltage Inputs

Input

Call for

Cooling

Voltage

Present

ECM/Y1 and ECM C

YES

Between 24VDC

and 32 VDC

NO NONE

EXT ECM/R and ECM C

YES 24VAC

NO NONE