26

ENVISION CONSOLE INSTALLATION MANUAL

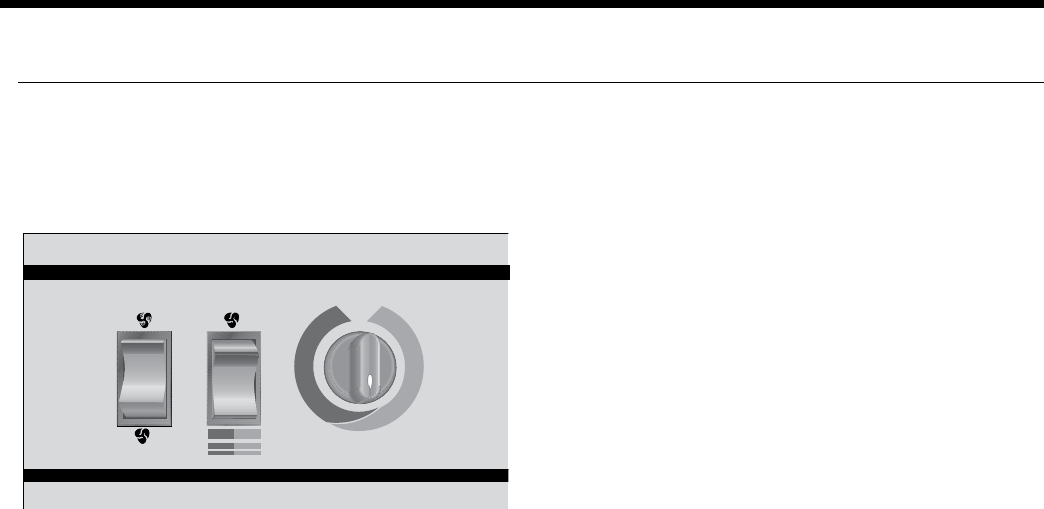

The user selects either “Heat/Cool” or “Fan Only” on the

mode switch, then either “High” or “Low” at the fan speed

switch. The temperature can be controlled by rotating the

thermostat control knob.

The “Fan Only” setting provides constant fan operation.

In the “Heat” mode, a call for heat by the thermostat closes

the compressor contactor contacts, energizing the com-

pressor, which will run until the thermostat is satisfied.

In the “Cool” mode, a call for cooling by the

thermostat energizes the reversing valve and closes the

compressor contactor contacts, energizing the compres-

sor, which will run until the thermostat is satisfied.

The emergency electric heat operation in the “Heat/Cool”

mode is subject to the setting of the internally mounted

mode switch. The optional, factory installed electric heat

will operate when the internally mounted mode switch is

in the “Emergency Heat” mode. In the “Heat” mode, a call

for heating energizes the fan and electric heater contactor,

energizing the electric heat elements and fan, which will

run until the thermostat is satisfied. When the internally

mounted mode switch is in the “Normal/Boilerless” mode

the unit operates in its normal “Heat/Cool” operation,

unless there is an aquastat controller. When the normally

open circuit of the aquastat closes and the unit is in the

heating mode, it will switch to the “Emergency Heat”

condition until the thermostat is satisfied or the aquastat

opens restarting the compressor.

If either the low or high pressure safety switches are

opened, the compressor and reversing valve are disabled

by the lockout relay. Unit operation will resume only after

the voltage to the unit is interrupted or the mode switch is

placed in the “Off” position.

If the electric heat limit switches are opened, the electric

heat is disabled.

Optional Versatec Microprocessor

Control Features

The Versatec microprocessor board provides control of

the entire unit as well as outputs for status modes, faults

and diagnostics. The control system is a microprocessor-

based control board that is located in the unit control box.

This feature is available for either unit mounted controls

or optional remote wall mounted thermostat. A 9-pin low

voltage terminal strip provides all necessary terminals for

the wall mounted thermostat.

Startup

The unit will not operate until all the inputs and safety

controls are checked for normal operating conditions.

Fault Retry

All faults are retried twice before finally locking the unit

out to prevent nuisance service calls.

Component Sequencing Delays

Components are sequenced and delayed for optimum unit

performance.

Short Cycle Protection and Random Start

The control allows a minimum on or off time of 5 minutes

for short cycle protection. A random time delay of 0 to

30 seconds is generated after each power-up to prevent

simultaneous start up of all units within a building after the

release from an unoccupied cycle or power loss.

Night Setback

A grounded signal to common or connecting 24 VAC to

the NS terminal will initiate the night setback mode.

Load Shed

A grounded signal to common or connecting 24 VAC to

the LS terminal places the controller into the load shed

mode. The compressor will become disabled and the fan

will start upon a thermostat call for heating or cooling.

Emergency Shutdown

A grounded signal to common or connecting 24 VAC to

the ES terminal places the controller into the emergency

shutdown mode. The compressor and fan operation are

suspended while in the emergency shutdown mode.

Condensate Overflow Protection

The board incorporates an impedance liquid sensor at the

top of the condensate drain pan. Upon a continuous 30-

second sensing of the condensate, the cooling operation of

the unit is suspended.

Safety Controls

The microprocessor board receives separate signals from

a high pressure switch for safety, a low pressure switch to

Figure 6: Unit Mounted Control

Envision Console Controls