Troubleshooting 75

I

nstruction Manual

S

ection 4: Troubleshooting

PN 51-6888Xi December 2012

ture at the cell that is different than what is noted on the calibration gas bottles. Always set

the calibration flow rate when a new diffuser is installed, and never readjust this flow rate until

another new diffuser is installed. For applications with heavy particulate loading, see "Probe

Passes Calibration, O

2

Still Reads Low". Always use a two stage pressure regulator for calibra-

tion gas.

2. No or improper reference air supplied.

4.5.1 Probe passes calibration, O

2

still reads high

External Reference Air Leak - There may be a leak that is permitting ambient air to mix with the

process gases. Since many combustion processes are slightly negative in pressure, ambient air

can be drawn into the cell area, biasing the O

2

reading upward.

1. Make sure that the calibration gas line is capped tightly between calibrations.

2. If autocal is used, make sure the check valve is seating properly.

3. If an abrasive shield is used, a small leak at the probe flange gasket can migrate down the

annular space between the probe OD and shield ID to the sensing cell causing a false high O

2

reading.

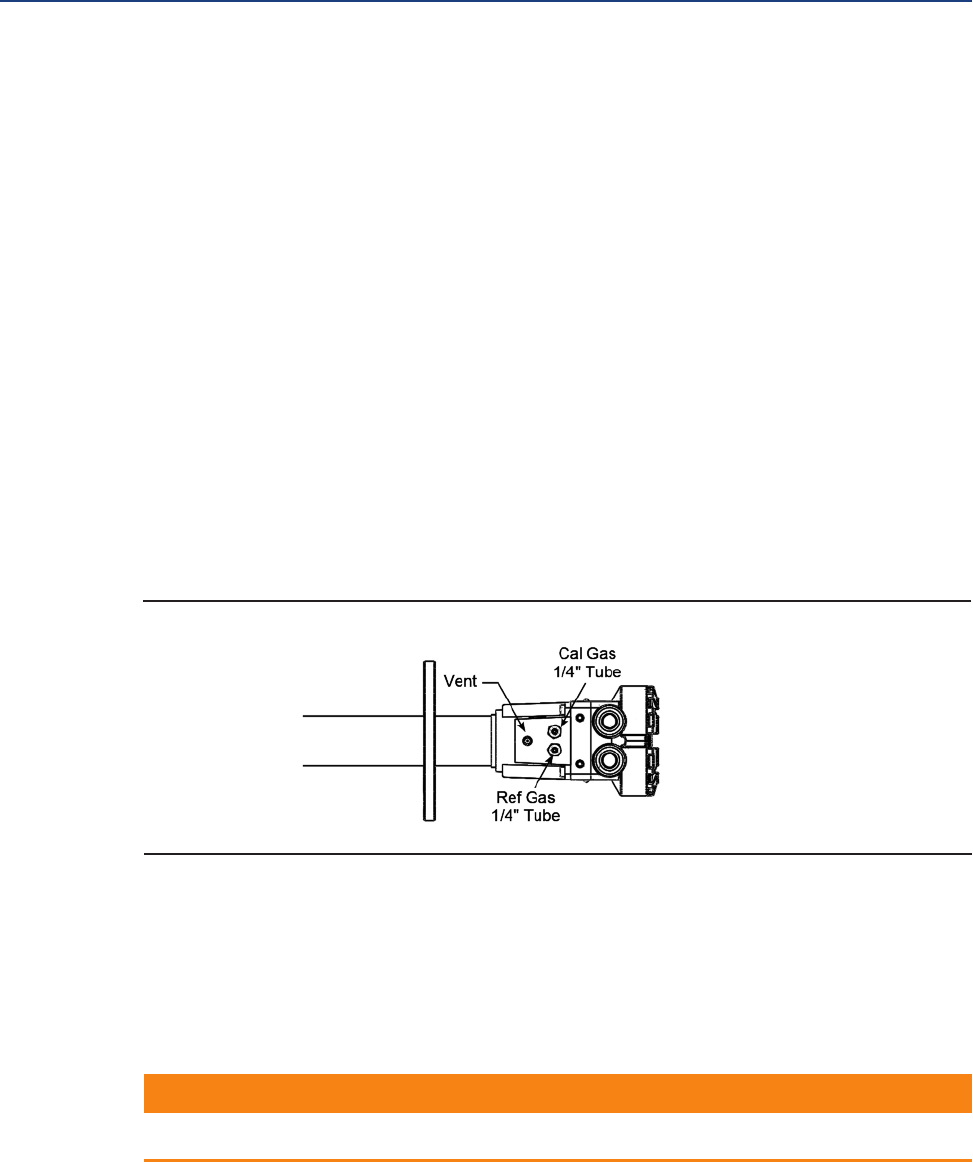

Internal Reference Air Leak - See Figure 4-2. There may be a leak inside the O

2

Probe itself, per-

mitting the reference air (20.95% O

2

) to mix with the process gases at the cell. To confirm this

leak condition, pressurize the inside (reference side) of the probe by plugging the reference air

exhaust port with your finger for 1 minute. (The conduit ports where the signal and power wires

pass may also need to be sealed.) The O

2

reading should decrease slightly. If the O

2

reading

increases during this test there is a leak inside the probe.

1. Acid condensation inside the probe can degrade the hose that carries the cal gas to the cell.

Inspect this hose. Dislodging or improper installation of the cal gas or reference air hose can

cause a leakage path.

2. The sensing cell is fastened to the end of the probe tube and uses a corrugated washer to sep-

arate the process gases from the ambient reference air. The corrugated washer may be dam-

aged by corrosion. Discard used washer.

NOTE

Aways install a new corrugated washer whenever the sensing cell is removed from the probe.

FIGURE 4-2. Probe Leakage Paths