76 Using AMS Device Manager to configure the meter

Section 4: Configuring a 3818 LNG Meter Daniel 3818 LNG Liquid Ultrasonic Meter Installation Manual

May 2012 3-9000-771 Rev A

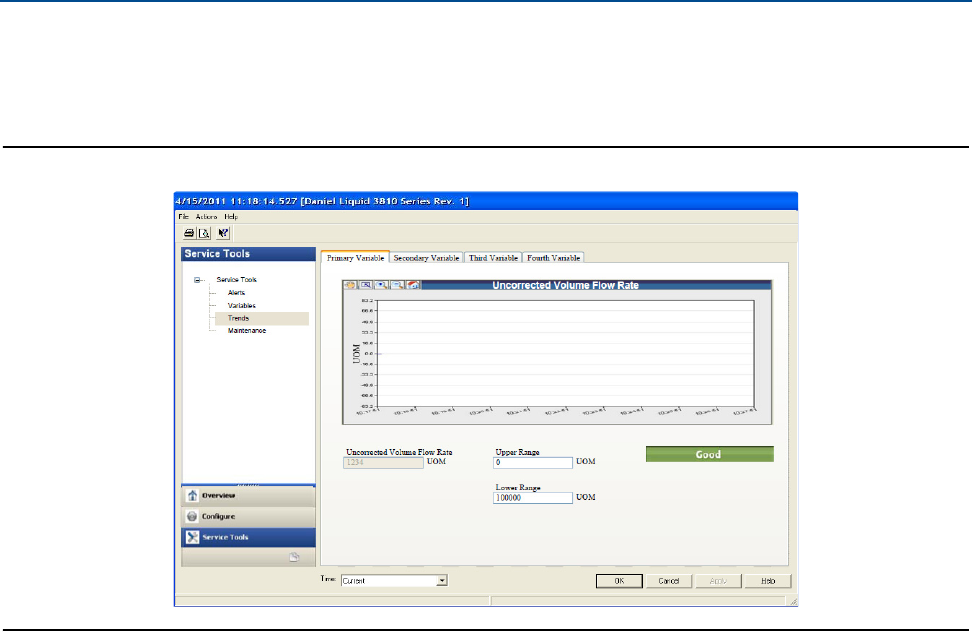

h. Click the Service Tools|Trends tab to display the device variables (uncorrected

volume flow rate, pressure and temperature) trends.

Figure 4-20 AMS Device Manager - Service Tools Trends

Primary and Secondary variables display real-time uncorrected volume flow rate

trends. The third and fourth variables charts displays trends for temperature and

pressure.

15. Click the

Service Tools|Routine Maintenance tab. Click Analog Output 1 Trim to perform a

digital to analog trim adjustment of the first milliamp output. The 4mA and 20mA

output current values should equal the plant’s standard values. Click

Yes to confirm the

configuration changes. Repeat this step to trim Analog Output 2 current. Click

Apply to

write the output trim values to the meter. Click

OK to navigate back to the Service Tools

page.

16. Click the

Service Tools|Zero Calibration tab. See AMS Device Manager - Guided Setup

Step 6. to configure the zero flow parameters.

17. After you have changed and written the configuration changes to the meter do the

following:

a. Enable the Write Protect switch on the CPU Module to protect the meter’s

configuration.

b. Replace the end cap and if required, apply security seals through the endcap

holes and through the hex head bolts that secure the Bracket/Cover to the Base

enclosure.

Note: The next time you connect to the device using Daniel MeterLink, the

Monitor page displays a Meter status alarm that the configuration has changed

and remains latched until acknowledged. Click the

Ack (acknowledge) button to

clear the alarm.