32

G. Performance Test of PVE

12/19/21 Piston Pump with “CV”,

“CVP”, “CVPC” and “CVPD”

Compensator Control

NOTE

Refer to Figure 24 for location of circuit components.

1. Open load valve one (1) and turn compensator adjust-

ment plug clockwise until seated.

2. Operate at 1200 RPM and 100 Psig outlet pressure until

all air is removed from the test circuit.

3. The case leakage as read at flow rater Q2 must exceed

10cc/minute. Make sure globe valve V2 is open.

4. Adjust globe valve V1 closed. Then adjust relief valve

three (3) to a pressure higher than the compensator setting

noted in Table 8.

5. Open globe valve V1 and set load valve one (1) for 100

Psig as read at gauge P2.

6. The unit must meet the following requirements at 1200

RPM and full stroke. See Table 7. Record the flow readings.

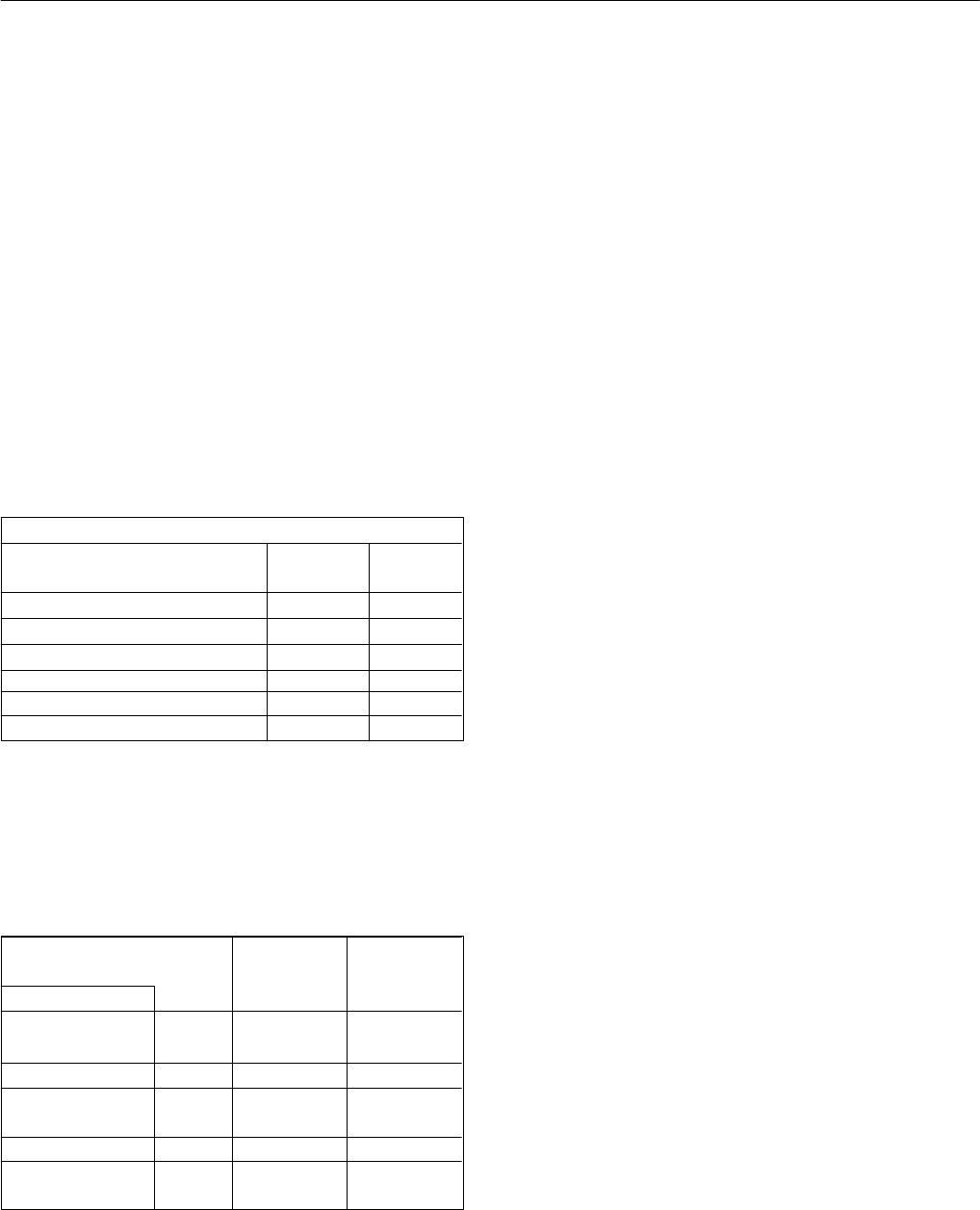

Model Code

Delivery

USgpm

Table 7. Maximum delivery and maximum case leakage.

Max. Case

Leakage

100 Psig System Pressure

1020cc/min

1020cc/min

800cc/min

1020cc/min

800cc/min

1020cc/min

11.5

11.5

12.5-13.5

12.45-13.45

13.75-14.85

13.7-14.8

PVE12*-*-**-CV-10

PVE12*-*-**CVP/CVP-11/CVPD

PVE19*-*-**-CV-10

PVE19*-*-**CVP/CVP-12/CVPD

PVE21*-*-**-CV-10

PVE21*-*-**CVP/CVPC-12/CVPD

7. Adjust load valve one (1) for pressures noted in Table 8.

Check the delivery loss by comparing flow at the highest system

pressure setting to the flow at 100 Psig. (Note: CVP and CVPC

compensators may require an adjustment to obtain a full stroke

at system pressure.) Make sure relief valve three (3) is not by-

passing fluid to tank. The unit must meet the following

requirements at full stroke and 1200 RPM.

Model Code

Delivery

Loss

Table 8. Delivery loss and maximum case leakage.

Max. Case

Leakage

System

Pressure

Psig

3000

2700

3000

2700

1.15 USgpm

3000 1.12 USgpm

PVE12*-*-**-CVP/

CVPC/CVPD

PVE19*-*-**-CV-10

PVE19*-*-**-CVP/

CVPC-12

PVE21*-*-**-CV-10

PVE21*-*-**-CVP/

CVPC-12

1.5 USgpm 1.45 USgpm

1.65 USgpm 1.70 USgpm

1.5 USgpm 1.45 USgpm

1.65 USgpm 1.70 USgpm

8. Units with a CV, CVP, or CVPC compensator S/A shall

perform the compensator control and integral case to inlet test.

Refer to steps F1 through F6. Set compensator pressure pres-

sure as shown in Table 6.

H. Load Sensing Control Test

1. At 1200 RPM, load the pump outlet port pressure to

2000 ± 50 Psig with load valve one (1). Shim the load sensing

compensator spool to obtain a differential pressure P1–P2 per

Table 9 with globe valve V1 adjusted for 6.5 ± .25 USGPM outĆ

let flow and gauge P1 at 2000 Psig.

2. Vary the outlet flow from 0.5 USGPM to maximum with

globe valve one (1). Pump outlet pressure must be stable.

3. Set globe valve one (1) fully open. Differential pressure

P2–P1 will be at minimum. Slowly close globe valve V1 while

observing the differential pressure gauge P2–P1 and flow rater

Q1. A point will be reached (compensator cracking pressure)

where flow will start to diminish; pressure gauge P2–P1 should

read the value noted in Table 9.

4. Cycle the pump from minimum to maximum flow with

globe valve one (1), pump outlet must be stable. At minimum

pump flow, the standby pressure P2 after P1 has decayed to

zero (0) must correspond to Table 9. Lockwire the compensator

adjustment plug.

5. Check for external leakage (none permissible).

6. Disconnect and drain the unit under test. Plug all open-

ings to prevent contamination.