17

G. Troubleshooting

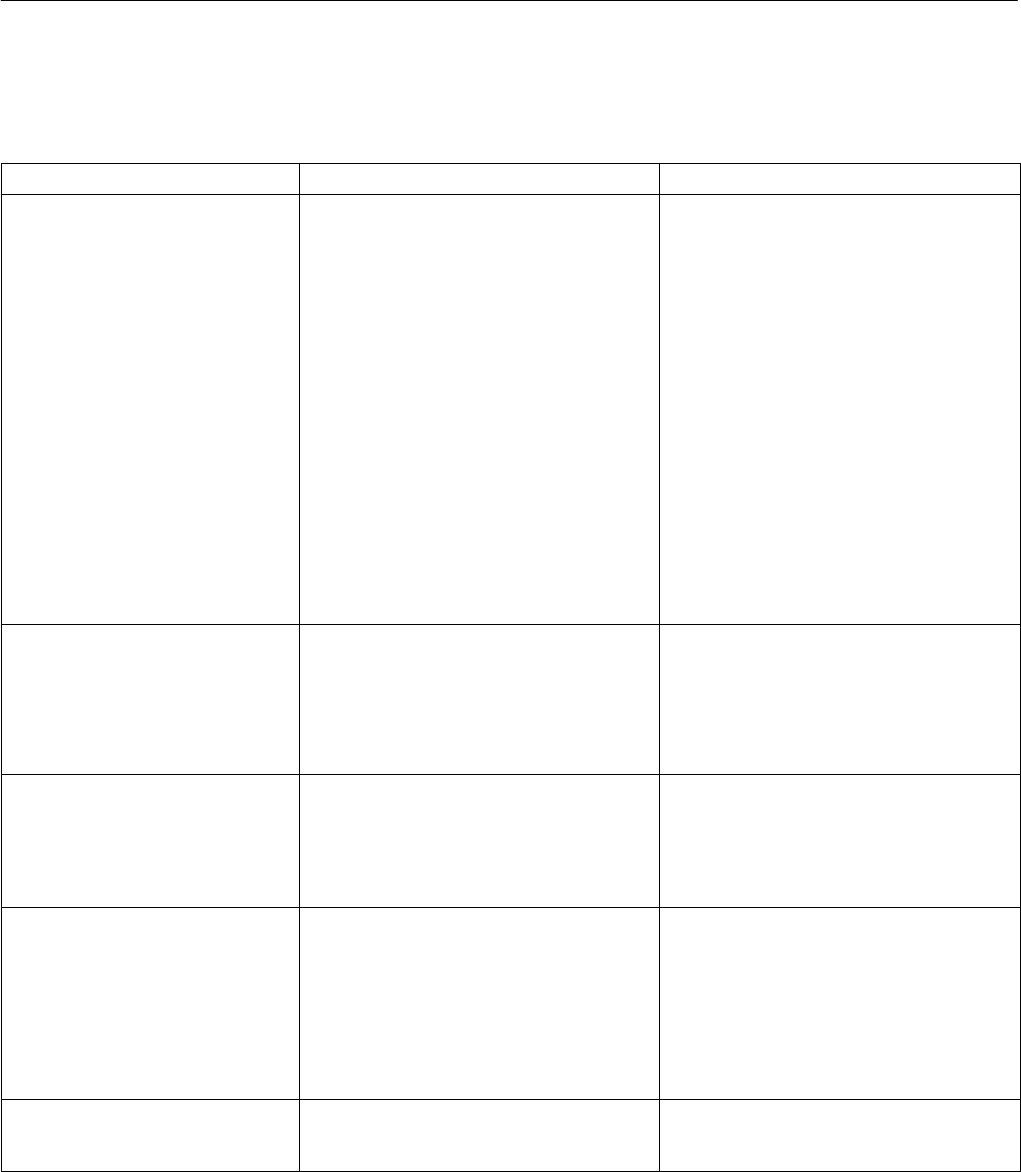

Table 3 lists the common difficulties experienced with piston

pumps and hydraulic systems. It also indicates probable

causes and remedies for each of the troubles listed.

TROUBLE PROBABLE CAUSE REMEDY

Excessive pump noise. Low oil level in the reservoir

Air in the system

Vacuum condition

Oil too thick

Cold weather

Fill reservoir to proper level with the

recommended transmission fluid. DO NOT

over fill transmission or damage may result.

Open reservoir cap and operate hydraulic

system until purged.

“Bleed” hydraulic lines at highest point

downstream of auxiliary pump and while

system is under pressure.

Check inlet (suction) lines and fittings for air

leaks.

Check auxiliary pump function.

Be certain correct type of oil is used for

refilling or adding to the system.

Run hydraulic system until unit is warm to

the touch and noise disappears.

Pump overheating Internal leakage

Heat exchanger not functioning

Fluid level low

If established that excessive internal

leakage is evident, return vehicle to

maintenance shop for evaluation and repair.

Locate trouble and repair or replace.

Add oil to operating level.

System not developing pressure Relief valve open

Compensator misadjusted

Loss of fluid internally (slippage)

Replace one or both. Do not attempt to

repair cartridges, they are factory

assembled and preset.

Return vehicle to maintenance shop for

repair of hydraulic system.

Loss of fluid Ruptured hydraulic lines

Loose fittings

Leaking gaskets or seals in pump or circuit

Check all external connections, tubing and

hoses. Tighten connections, replace

ruptured tube or hose.

Observe mating sections of hydrostatic

transmission for leaks. Replace seals or

gaskets if possible.

Replace seals or gaskets if possible.

Miscellaneous Sheared shaft key

Disconnected or broken drive mechanisms

Locate and repair.

Table 3. Troubleshooting Chart