36

IX Start-up and Checkout

NOTE

SAFE LIGHTING AND OTHER PERFORMANCE CRITERIA WERE MET WITH THE GAS MANIFOLD AND

CONTROL ASSEMBLY PROVIDED ON THE BOILER WHEN THE BOILER UNDERWENT THE TESTS SPECIFIED

IN Z21.13

Use the following procedure for initial start-up of the boiler:

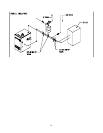

1) Make sure that the boiler and system are filled with water.

WARNING

• IF ANTIFREEZE IS USED IN THE SYSTEM, IT MUST BE A NONTOXIC TYPE SUCH AS PROPYLENE

GLYCOL.

• NEVER ATTEMPT TO FILL A HOT EMPTY BOILER.

2) Check all new piping for leaks and purge piping sections that are filled with air. See Part 4 of the National Fuel Gas Code

for additional information on testing and purging gas lines.

WARNING

• NEVER USE A FLAME TO CHECK FOR GAS LEAKS.

• MAKE SURE THAT THE AREA AROUND THE BOILER IS CLEAR AND FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE, AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

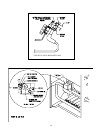

3) Vent system must be complete and free of obstructions before attempting to fire boiler. Make sure that the silicone cure

time called for in the vent assembly instructions has passed before firing boiler.

4) Inspect all line voltage wiring for loose or uninsulated connections.

5) Start the boiler using the lighting instructions on page 36.

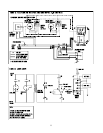

6) Inspect the pilot and main flames. These flames should be stable and mostly blue (Fig. 37, 38). No yellow tipping should

be present; however, intermittent flecks of yellow and orange in the flames are normal.

7) Check the manifold pressure and adjust if necessary. To do this, use the following procedure.

WARNING

FAILURE TO FOLLOW THE FOLLOWING PROCEDURE EXACTLY COULD RESULT IN OVERFIRING OF THE

BOILER AND A CARBON MONOXIDE HAZARD.

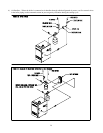

a) Connect a manometer to the line pressure tap on the gas valve

b) Check the line pressure with all gas appliances on and off. The line pressure at the boiler must be within the following

limits regardless of what combination of appliances is firing:

Line Press (inches w.c.) Natural Gas LP Gas

Min. 5.0 11.0

Max. 14.0 13.0

NOTE

The combustion chamber insulation panels in this boiler contain a cornstarch based binder which may emit a strong

odor as it is burned out of the insulation when the boiler is fired for the first time. An hour or more of continuous

firing may be required to burn off all of this binder. Open any windows and outside doors in the boiler room to

maximize ventilation while this binder is burned out.