19

4) Assembly of Flex-L-Intl. Star-34 Vent System:

a) Star-34 General Notes:

• Do not cut Star-34 vent components.

• Support horizontal piping sections at intervals of 48” or less.

• Vertical venting systems must be supported by at least one Star-34 Firestop. An additional vertical support is required

after any offset.

• Orient Star-34 components so that the arrows on the piping labels are in the direction of flue gas flow.

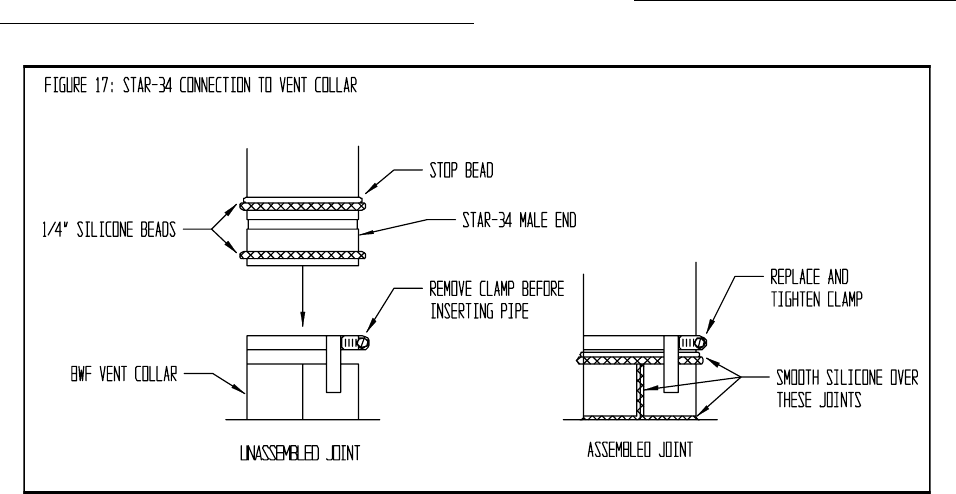

b) Start assembly of the vent system at the boiler. Remove the hose clamp shipped on the BWF vent collar. Bend the three

hose clamp tabs on this collar outward slightly.

c) Clean the exterior of the male end of the first piece of pipe and the inside of the vent collar on the boiler. Use a cleaner

such as Methyl Ethyl Keytone (MEK) or naptha.

d) On the male end of the pipe, apply a ¼” wide bead of silicone approximately ¼” from the end of the pipe and another ¼”

bead against the joint side of the stop bead (Fig 17).

e) Insert the male end of the pipe into the boiler vent collar until it bottoms out.

f) Apply an additional bead of silicone over the outside of the joint and smooth out. Also apply silicone over the seams in

the vent collar (Fig 17).

g) Replace and tighten the clamp on the vent collar.

h) Clean the female end of the first piece of pipe. Also clean the male end of the next piece of pipe.

i) Apply silicone as in step (d) (Fig 18).

j) Align the longitudinal seams of the pipe and insert the male end of the second pipe into the female end of the first pipe.

k) Insert a StaR joiner band into the inlet of the beaded channel. Feed the joiner band in so that it makes its way around the

channel and overlaps by approximately ½” (Fig 18).

l) Cut the excess joiner band so that it lays flat in the beaded channel (Fig 18).

m) Fill the inlet of the beaded channel with silicone. Smooth the silicone over the channel inlet as well as the silicone

between the female end and the stop bead of the male end (Fig 18).

n) Repeat Steps (h) – (m) for the remaining Star-34 components. If a termination elbow or tee is used, use this procedure to

complete the exhaust system.

o) To connect Star-34 to the VH-1 terminal, the vent system must be configured so that the female end of the last piece of

Star-34 will fit over the vent connection on the terminal. Before permanently making this joint, clean both the male end of

the terminal and the female end of the last piece of pipe with Methyl Ethyl Keytone or Naptha. Apply a ¼ inch bead of

silicone ¼” from the male end of the terminal. Also apply a ¼” bead of silicone along the weld seam on the inside of the

female section of the Star-34 pipe. Slip the female end of the vent pipe over the male end of the terminal until it is over at

least 1 ¼ inches of the terminal. Apply a second bead of silicone over the joint between the vent pipe and the terminal as

well as over the channel inlet. Do not attempt to use a locking band at this joint. Install a pipe support or other means to

prevent the Star-34 pipe from separating from the terminal.

p) Allow the silicone to cure for 24 hours before operating the boiler.