27

7) Manual Reset High Limit (Required by some codes) – This control is required by ASME CSD-1 and some other codes.

Install the high limit in the boiler supply piping just beyond the boiler with no intervening valves. Set manual reset high

limit as far above the operating limit setting as possible, but not over 240F. Wire the control to break the 120 VAC

electrical supply to the boiler.

8) Flow control valve (Required under some conditions) – The flow control valve prevents flow through the system unless

the circulator is operating. A flow control valve may be necessary on converted gravity systems to prevent gravity

circulation. Flow control valves are also used to prevent “ghost flows” in circulator zone systems through zones that are

not calling for heat.

9) Isolation Valves (Optional) – Isolation valves are useful if the boiler must be drained, as they will eliminate having to

drain and refill the entire system.

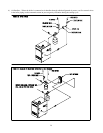

10) Drain Valve – The drain valve is shipped in the boiler parts bag. Install it in the ¾” opening in the tee on the boiler return

(Figure 1).

Piping for Special Situations

Certain types of heating systems have additional requirements. Some of the more common variations follow:

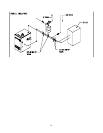

1) Indirect Water Heaters – Figure 28 shows typical indirect water heater piping. Boiler piping is the same as for any two-

zone system. Figure 28 shows circulator zoning, which is usually preferred for indirect water heaters. Size the circulator

and indirect water heater piping to obtain the boiler water flow through the indirect water heater called for by the indirect

water heater manufacturer.