17

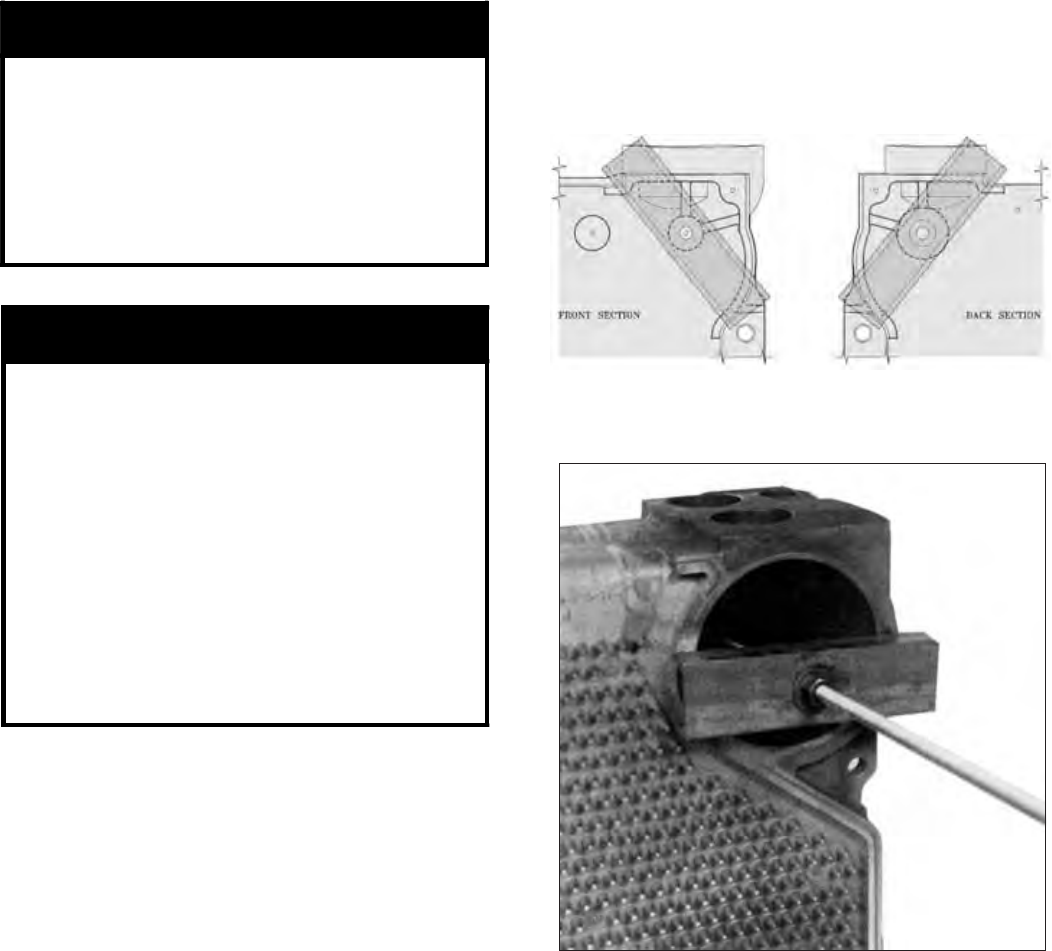

Figure 11: Center Section Channel Block Position

(Partial Block Draw-Up)

Figure 10: Front and Rear Section Channel

Block Positions (Hydraulic Draw-up)

CAUTION

Do not apply pressure directly on threaded

tappings on front and rear sections with

draw-up channels during assembly

procedures.

Rods should be approximately centered in

openings so that rods and couplings (when

used) do not drag on pipe thread in end

section tappings.

WARNING

READ THE STATEMENTS BELOW BEFORE

ATTEMPTING TO USE HYDRAULIC EQUIPMENT.

*

*

*

*

Re

lease pressure in ram pumps before

attempting to remove clamps.

Do not stand in line with draw-up rods at

either end when hydraulic pressure is

being applied. As a safety measure,

ends of draw-up rods should be covered

while sections are being drawn in case

rods should snap while under tension.

Do not operate ram against draw-up

coupling.

Do not operate pump after ram has

reached stroke limit.

e. Draw-Up Sections

Use hydraulic rams to draw up sections by

applying pressure alternately on the draw-up

rods. When rams reach stroke limit, release

pressure in ram pumps and then move clamps to

new position.

f. Continue to draw-up until all sections make

contact at the ground joints.

g. After all sections have been drawn up, but before

removing the hydraulic rams and draw-up rods,

the 9¾” long tie rods must be installed.

The large draw-up rod lugs with dual holes

are cast in the four (4) corners of each casting.

Starting with the upper holes in the back section,

install four (4) 5/8” x 9¾” long tie rods along

with washers and nuts. Continue installing the

tie rods alternating from the upper to lower set

of holes in draw-up lugs until front section is

secured. Be certain that all sections are drawn

up IRON TO IRON at all three nipple ports.

h. Excess length of draw-up rods must not extend

beyond front and rear section. To ensure proper

fit of jacket, adjust accordingly. Tighten all tie

rod nuts until finger tight. Then tighten them

an additional ½ turn with a wrench to prevent

section damage to thermal expansion.

tapped holes in the front section. Be sure to

screw draw-up rods into couplings far enough to

prevent stripping threads.

d. Place a 3” x 12” lg. steel channel on each end of

the upper draw-up rod and a 3” x 8½” lg. steel

channel on each end of the lower draw-up rods.

Refer to Figures 10 and 11 for proper placement

of channel block during assembly procedures.

Install nuts and washers on one end of the draw-

up rods and the hydraulic rams, washers and

draw-up rod clamps on the other. See Figure 13.