10

SECTION I - GENERAL INFORMATION (CONTINUED)

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated boiler to the carrier in good

condition.

2. ANY CLAIMS for damage or shortage in shipment

must be filed immediately against the carrier by the

consignee. No claims for variances from, or short-

age in orders, will be allowed by the manufacturer

unless presented within sixty (60) days after the

receipt of goods.

3. Make sure that appropriate items on the Master Parts

List (pg 59) are all on hand.

B. LOCATE THE UNIT

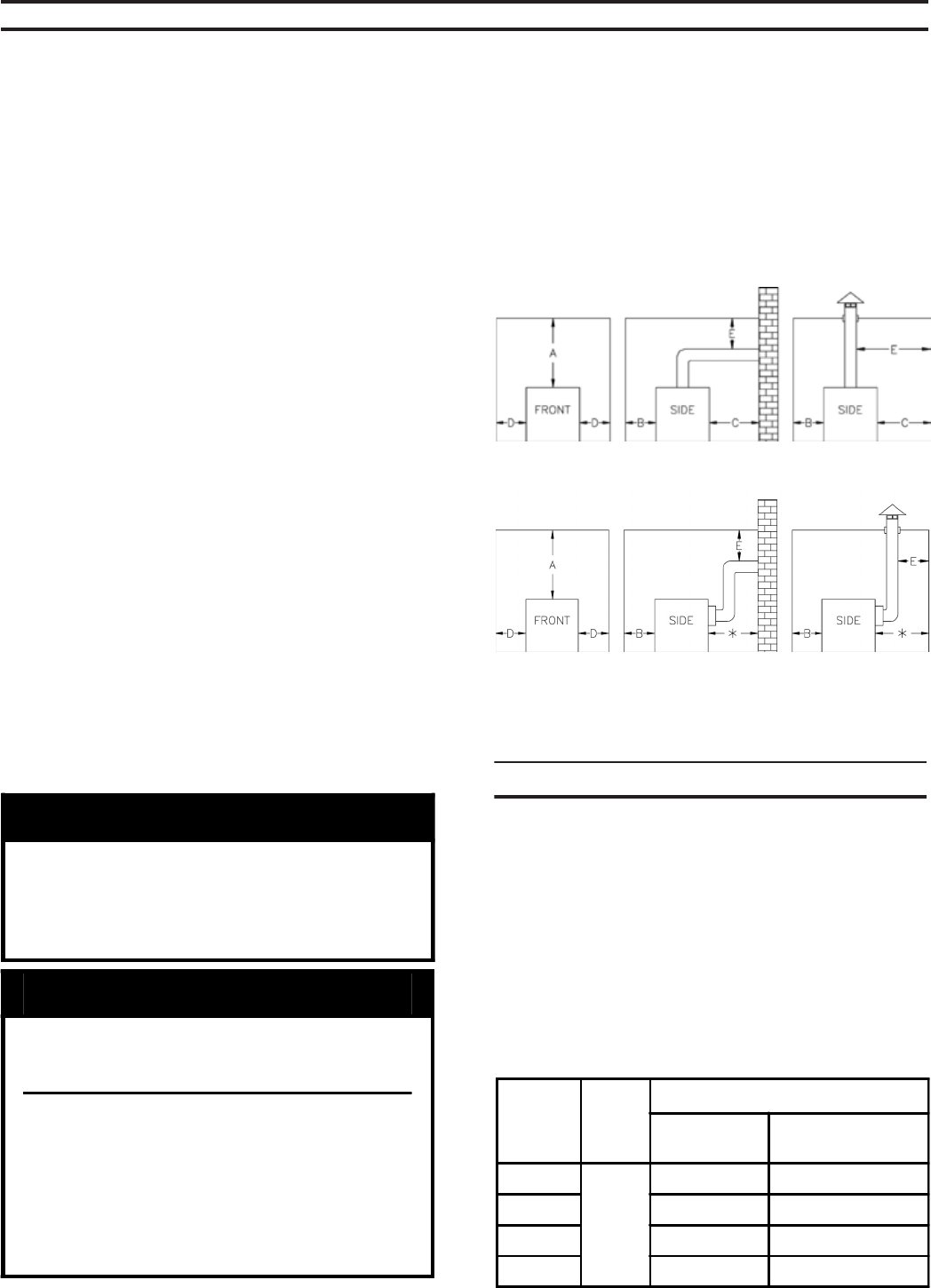

1. RECOMMENDED SERVICE CLEARANCE

- Locate the unit in the boiler room so as to

provide ease of venting and adequate clearance

for maintenance, serviceability, and installation of

piping. Refer to Figure 1 for boiler dimensional

data.

FRONT — Provide 43” service clearance for

removal, maintenance, and servicing of burner and

controls.

REAR — Provide a minimum clearance from the

boiler jacket for access to flame observation port,

rear flue damper and vent piping, relief valve, and

boiler return piping. See Table III.

LEFT SIDE — Provide a minimum clearance from

the boiler jacket of 26” for cleaning of flueways and

installation and removal of tankless heater(s).

RIGHT SIDE — Provide a minimum clearance from

Table II: Minimum Clearances To Combustible

Materials (Inches)

Boilers with Top Flue Outlet

Boilers with Rear Flue Outlet

Flue

Outlet

Size

Top

Flue

Outlet

Rear Flue Outlet

Combustible

Surfaces

Non-Combustible

Surfaces

7" Dia.

18"

37" 22"

8" Dia. 38" 23"

10" Dia. 40" 25"

12" Dia. 43" 28"

NOTICE

Recommended clearance for service may be

reduced to minimum clearance to

combustible material. However, increased

service and maintenance difficulty will

result.

WARNING

Boiler is suitable for installation on

combustible floor. Do not install boiler

on carpeting.

Floor construction should have

adequate load bearing characteristics

to bear the weight of the boiler filled

with water (see Table 1). A boiler

foundation similar to the one shown in

Figure 2 is recommended if the boiler

room floor is weak or uneven or if a

water condition exists.

A

evobA

B

tnorF

C

raeR

D

sediS

E

rotcennoCtneV

6 42 6 6 81

sseccaotecnaraelcecivresdednemmoceRrofIIIelbaTeeS*

reliobforaer

lanoitaNnaciremAhtiwylpmocsecnaraelcdetsiL:1ETON

.tnempiuqegninrubliofonoitallatsnI,13APFN/ISNAdradnatS

htiwsmoornidellatsniebnacsreliob42seireS:2ETON

detsiL.evobadetsilsalairetamelbitsubmocmorfsecnaraelc

tesolcroevoclarofdecuderebtonnacsecnaraelc

.snoitallatsni

,lairetamelbitsubmocotsecnaraelcdecuderroF:3ETON

evobaehtnidebircsedsadedivorpebtsumnoitcetorp

.dradnats13APFN/ISNA

Table III: Recommended Rear Service Clearance

the boiler jacket of 12”.

T

OP — Provide a minimum clearance from the

boiler jacket of 24”

2. FOR MINIMUM CLEARANCES to combustible

materials, See Table II.

3. PROVIDE ADEQUATE FOUNDATION for the

unit. Refer to Figure 2.