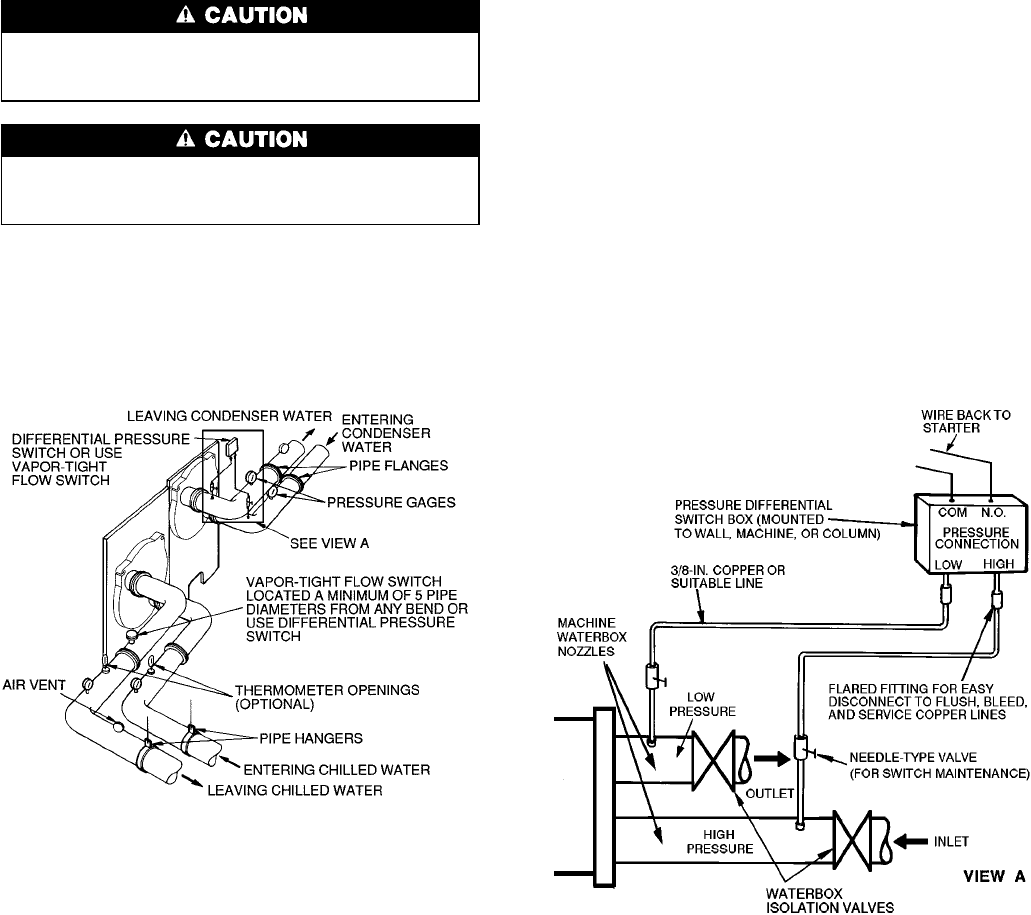

Connect Piping

INSTALL WATER PIPING TO HEAT EXCHANGERS —

Install piping using job data, piping drawings, and proce-

dures outlined below. A typical piping installation is shown

in Fig. 14.

Factory-supplied insulation is not flammable but can be

damaged by welding sparks and open flame. Protect in-

sulation with a wet canvas cover.

Remove chilled and condenser water sensors before

welding connecting piping to water nozzles. Refer to

Fig. 9. Replace sensors after welding is complete.

1. Offset pipe flanges to permit removal of waterbox cover

for maintenance and to provide clearance for pipe clean-

ing. No flanges are necessary with marine waterbox

option; however, water piping should not cross in front

of the waterbox or access will be blocked.

2. Provide openings in water piping for required pressure

gages and thermometers. For thorough mixing and tem-

perature stabilization, wells in the leaving water pipe should

extend inside pipe at least 2 in. (50 mm).

3. Install air vents at all high points in piping to remove air

and prevent water hammer.

4. Install pipe hangers where needed. Make sure no weight

or stress is placed on waterbox nozzles or flanges.

5. Water flow direction must be as specified in Fig. 15-18.

NOTE: Entering water is always the lower of the 2 nozzles.

Leaving water is always the upper nozzle for cooler or

condenser.

6. Water flow switches must be of vapor-tight construction

and must be installed on top of pipe in a horizontal run

and at least 5 pipe diameters from any bend.

7. Install waterbox vent and drain piping in accordance with

individual job data. All connections are

3

⁄

4

-in. FPT.

8. Install waterbox drain plugs in the unused waterbox drains

and vent openings.

9. Install optional pumpout system or pumpout system and

storage tank as shown in Fig. 19-22.

LEGEND

COM — Common

N.O. — Normally Open

*Do not tap connections after shutoff valve.

Fig. 14 — Typical Nozzle Piping

*

*

19