Free-Standing, Field-Installed Starter — Assemble and in-

stall compressor terminal box in desired orientation, and cut

necessary conduit openings in conduit support plates. See

Fig. 27 and 29. Attach power leads to compressor terminals

in accordance with job wiring drawings, observing caution

label in terminal box. Use only copper conductors. The mo-

tor must be grounded in accordance with NEC (National Elec-

trical Code), applicable local codes, and job wiring diagrams.

Installer is responsible for any damage caused by improper

wiring between starter and compressor motor.

IMPORTANT: Do not insulate terminals until wiring

arrangement has been checked and approved by

Carrier start-up personnel. Also, make sure correct phas-

ing is followed for proper motor rotation.

Insulate Motor Terminals and Lead Wire Ends — Insulate

compressor motor terminals, lead wire ends, and electrical

wires to prevent moisture condensation and electrical arc-

ing. For low-voltage units (up to 600 v), obtain insulation

material from machine shipping package consisting of 3 rolls

of insulation putty and one roll of vinyl tape.

1. Insulate each terminal by wrapping with one layer of in-

sulation putty.

2. Overwrap putty with 4 layers of vinyl tape.

High Voltage Units — High-voltage units require special ter-

minal preparation. Follow local electrical codes for high-

voltage installation. Vinyl tape is not acceptable; a high voltage

terminal method must be used.

Connect Power Wires to Oil Pump Starter — See Fig. 30.

Connect power wires to oil pump starter mounted in ma-

chine power panel. Use separate fused disconnect or circuit

breaker as shown on job wiring diagrams and Fig. 30. Check

that power supply voltage agrees with oil pump voltage. Fol-

low correct phasing for proper motor rotation.

Do not punch holes or drill into the top surface of the

power panel. Knockouts are provided in the bottom of

the power panel for wiring connections.

Piping

Control Wiring

Power Wiring

LEGEND

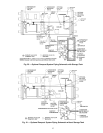

1—Disconnect

2—Free-Standing Compressor Motor Starter

3—Compressor Motor Terminal Box

4—Chiller Power Panel

5—Control Cabinet

6—Vents

7—Pressure Gages

8—Chilled Water Pump

9—Condenser Water Pump

10 — Chilled Water Pump Starter

11 — Condensing Water Pump Starter

12 — Cooling Tower Fan Starter

13 — Disconnect

14 — Oil Pump Disconnect (see Note 4)

IMPORTANT: Wiring and piping shown are for general point-

of-connection only and are not intended to show details for a

specific installation. Certified field wiring and dimensional dia-

grams are available on request.

NOTES:

1. All wiring must comply with applicable codes.

2. Refer to Carrier System Design Manual for details regarding pip-

ing techniques.

3. Wiring not shown for optional devices such as:

• remote start-stop

• remote alarm

• optional safety device

• 4 to 20 mA resets

• optional remote sensors

4. Oil pump disconnect may be located within the enclosure of Item

2 — Free-Standing Compressor Motor Starter.

Fig. 27 — 19XR with Free-Standing Starter

31