To Rig Compressor

NOTE: The motor end of the 19XR compressor is heavy

and will tip backwards unless these directions are followed:

1. Cut two 4 in. × 6 in. wooden beams to the same length

as the compressor.

2. Drill holes into the beams and bolt them to the base of

the compressor.

Additional Notes

1. Use silicon grease on new O-rings when refitting.

2. Use gasket sealant on new gaskets when refitting.

3. Cooler and condenser vessels may be rigged vertically.

Rigging should be fixed to all 4 corners of the tube sheet.

Install Machine Supports

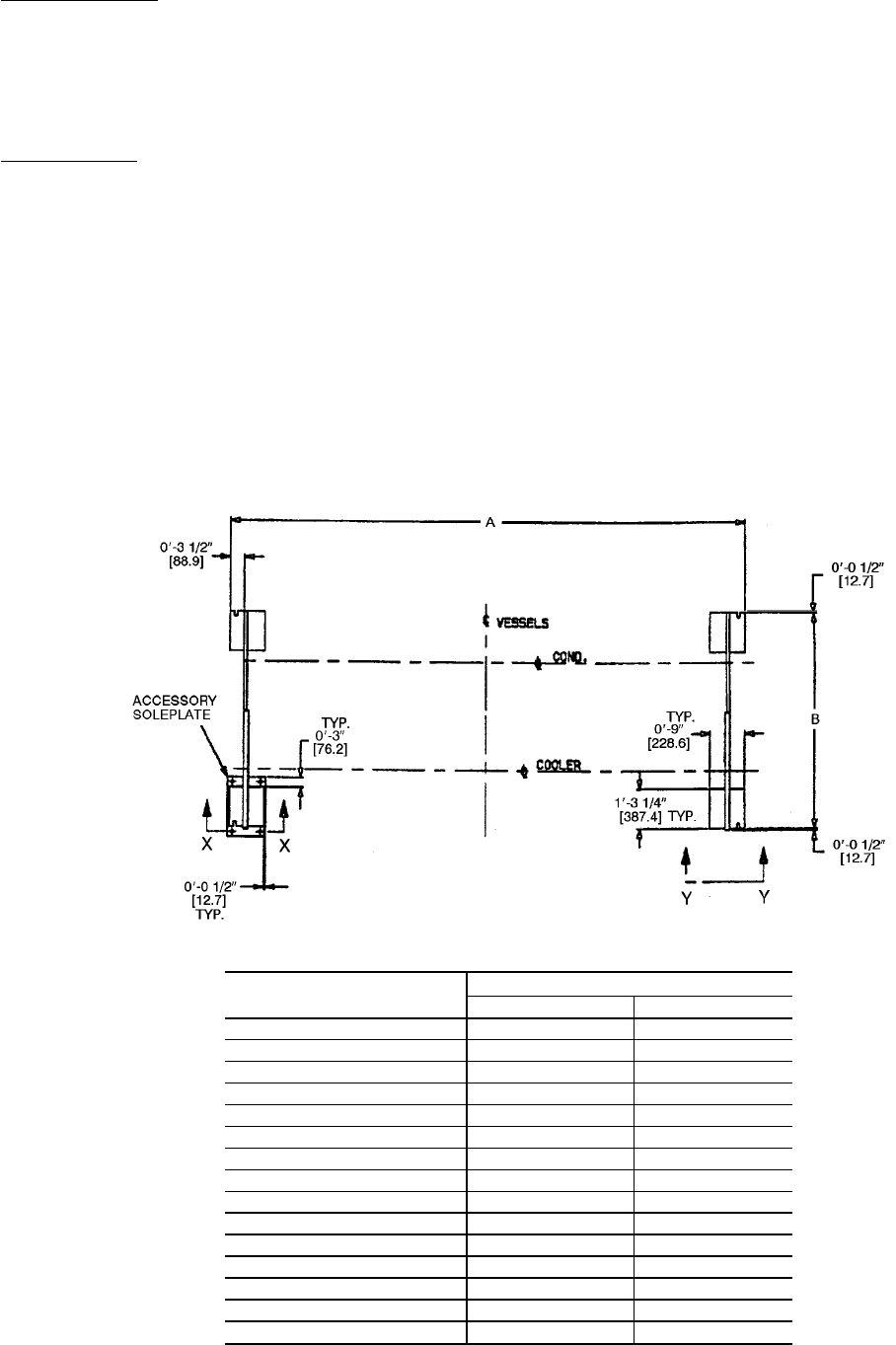

INSTALL STANDARD ISOLATION — Figures 10 and 11

show the position of support plates and shear flex pads, which

together form the standard machine support system.

INSTALL ACCESSORY ISOLATION (if required) — Un-

even floors or other considerations may dictate the use of

accessory soleplates (supplied by Carrier for field installa-

tion) and leveling pads. Refer to Fig. 10 and 12.

Level machine by using jacking screws in isolation sole-

plates. Use a level at least 24-in. (600 mm) long.

For adequate and long lasting machine support, proper grout

selection and placement is essential. Carrier recommends that

only pre-mixed, epoxy type, non-shrinking grout be used for

machine installation. Follow manufacturer’s instructions in

applying grout.

1. Check machine location prints for required grout

thickness.

2. Carefully wax jacking screws for easy removal from grout.

3. Grout must extend above the base of the soleplate and

there must be no voids in grout beneath the plates.

4. Allow grout to set and harden, per manufacturer’s in-

structions, before starting machine.

5. Remove jacking screws from leveling pads after grout has

hardened.

HEAT EXCHANGER

SIZE

DIMENSIONS (ft-in.)

AB

10-12 10- 7

1

⁄

4

4-11

1

⁄

4

15-17 12-10

3

⁄

4

4-11

1

⁄

4

20-22 10- 7

1

⁄

4

5- 5

1

⁄

4

30-32 12-10

3

⁄

4

5- 4

1

⁄

4

35-37 14- 7

1

⁄

4

5- 4

1

⁄

4

40-42 12-10

3

⁄

4

6- 0

45-57 14- 7

1

⁄

4

6- 0

50-52 12-10

3

⁄

4

6- 5

1

⁄

2

55-57 14- 7

1

⁄

4

6- 5

1

⁄

2

60-62 12-10

3

⁄

4

6- 9

1

⁄

2

65-67 14- 7

1

⁄

4

6- 9

1

⁄

2

70-72 15- 1

7

⁄

8

7-10

1

⁄

2

75-77 17- 1

7

⁄

8

7-10

1

⁄

2

80-82 15- 1

7

⁄

8

8- 9

3

⁄

4

85-87 17- 1

7

⁄

8

8- 9

3

⁄

4

Fig. 10 — 19XR Machine Footprint

17