3. Check electrical connections for tightness and controls for

proper operation each heating (heat pump only) or cooling

season and service as necessary.

CAUTION: Because of possible damage to the equip-

ment or personal injury, maintenance should be per-

formed by qualified personnel only.

COIL CLEANING

1. Remove top cover. See Remove Top Cover section.

CAUTION: Coil fin damage can result in higher oper-

ating costs or compressor damage. Do not use flame,

high-pressure water, steam, or volatile or corrosive clean-

ers on fins or tubing.

2. Clean coil using vacuum cleaner and its crevice tool. Move

crevice tool vertically, close to area being cleaned, making

sure tool touches only the dirt on the fins and not the fins.

To prevent fin damage, do not scrub fins with tool or move

tool horizontally against fins.

3. If oil deposits are present, spray coil with ordinary house-

hold detergent. Wait 10 minutes, and proceed to next step.

4. Using garden hose, spray coil vertically downward with

constant stream of water at moderate pressure. Keep nozzle

ata15° to 20° angle, about 3 in. from coil face and 18 in.

from tube. Spray so debris is washed out of coil and

basepan.

5. Restore power to unit.

CLEANING OUTDOOR FAN MOTOR AND BLADE

1. Remove fan motor and blade. Refer to Remove Fan-Motor

Assembly section of this manual. Be careful not to bend or

dent fan blade.

2. Clean motor and blade with soft brush or cloth. Be careful

not to disturb balance weights on fan blade.

3. Check fan-blade setscrew for tightness.

4. Reinstall fan motor and blade to top cover and check for

alignment.

5. Reinstall top cover and position blade as per Fig. 24.

6. Reconnect electrical power and check for proper operation.

ELECTRICAL CONTROLS AND WIRING

1. Disconnect power to both the outdoor and indoor units.

2. Check all electrical connections for tightness. Tighten all

screws on electrical connections. If any connections appear

to be burned or smoky, disassemble the connection, clean

all parts and stripped wires, and reassemble. Use a new

connector if old one is burned or corroded and crimp

tightly.

3. Reconnect electrical power to the indoor and outdoor units

and observe unit through 1 complete operating cycle.

4. If there are any discrepancies in the operating cycle,

troubleshoot to find the cause, and correct.

REFRIGERANT CIRCUIT

1. Check the refrigerant charge using the superheat or sub-

cooling method, whichever is applicable. If low on charge,

check unit for leaks using an electronic leak detector.

2. If any leaks are found, recover or isolate charge (pump-

down) if applicable and make necessary repairs.

3. Evacuate, recharge, and operate unit through entire cycle.

FINAL CHECKOUT

After the unit has been operating, the following items should be

checked:

1. Check that unit operational noise is not excessive due to

vibration of components, tubing, panels, etc. If present,

isolate problem and correct.

2. Check to be sure caps are installed on service valves and

that they are tight.

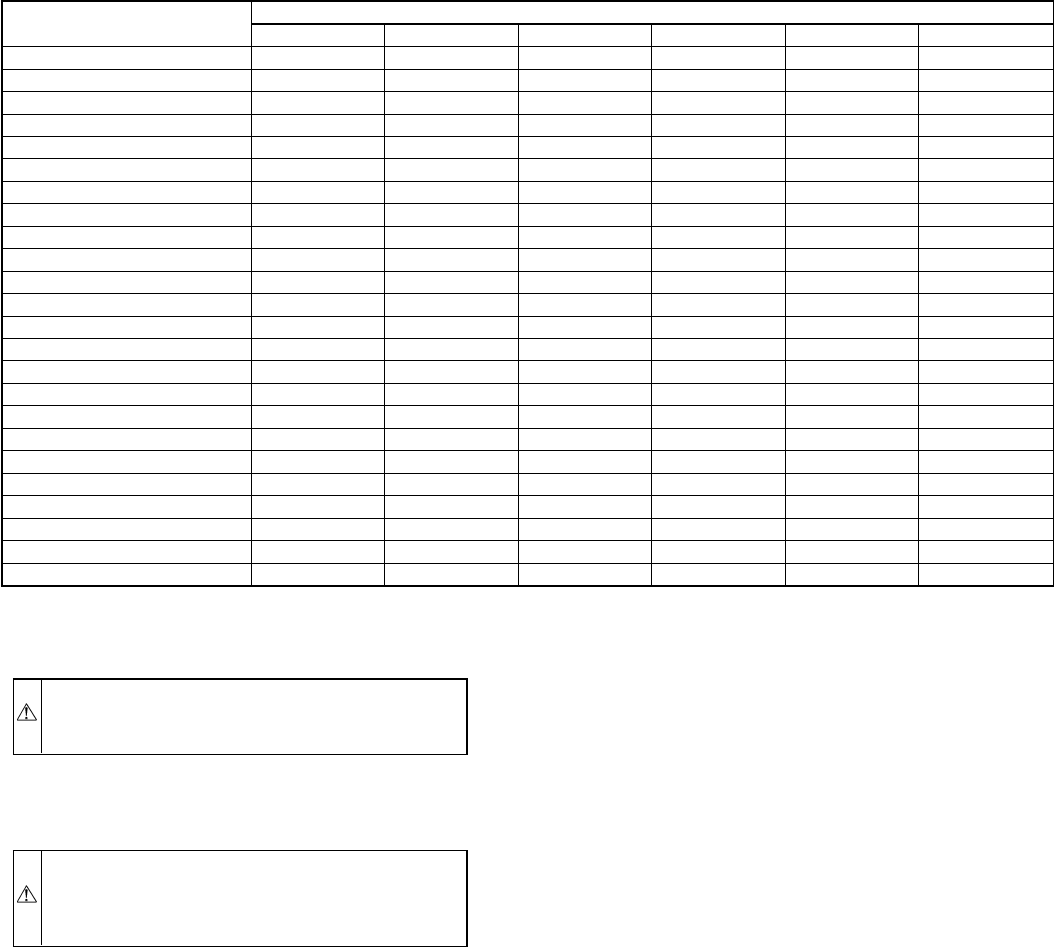

TABLE 24—REQUIRED LIQUID-LINE TEMPERATURE

PRESSURE (PSIG)

AT SERVICE FITTING

REQUIRED SUBCOOLING TEMPERATURE (°F)

0 5 10 15 20 25

134 76 71 66 61 56 51

141 79 74 69 64 59 54

148 82 77 72 67 62 57

156 85 80 75 70 65 60

163 88 83 78 73 68 63

171 91 86 81 76 71 66

179 94 89 84 79 74 69

187 97 92 87 82 77 72

196 100 95 90 85 80 75

205 103 98 93 88 83 78

214 106 101 96 91 86 81

223 109 104 99 94 89 84

233 112 107 102 97 92 87

243 115 110 105 100 95 90

253 118 113 108 103 98 93

264 121 116 111 106 101 96

274 124 119 114 109 104 99

285 127 122 117 112 107 102

297 130 125 120 115 110 105

309 133 128 123 118 113 108

321 136 131 126 121 116 111

331 139 134 129 124 119 114

346 142 137 132 127 122 117

359 145 140 135 130 125 120

—46—