2. Measure liquid service-valve pressure by attaching an

accurate gage to the service port.

3. Measure the liquid-line temperature by attaching an accu-

rate thermistor-type or electronic thermometer to the liquid

line near the outdoor coil.

4. Refer to unit-rating plate to find required subcooling

temperature for units produced during or after January

1993. For units produced through December 1992, refer to

Table 23. Find the point at which the required subcooling

temperature intersects the measured liquid service-valve

pressure on Table 24.

5. To obtain the required subcooling temperature at a specific

liquid-line pressure, add refrigerant if liquid-line tempera-

ture is higher than indicated or remove refrigerant if

temperature is lower. Allow a tolerance of 3°F.

CARE AND MAINTENANCE

To assure high performance and minimize possible equipment

malfunction, it is essential that maintenance be performed periodi-

cally on this equipment. The frequency with which maintenance is

performed is dependent on such factors as hours of operation,

geographic location, and local environmental conditions.

WARNING: Disconnect all electrical power to unit

before performing any maintenance or service on outdoor

unit. Remember to disconnect power supply to air handler

as this unit supplies low-voltage power to the outdoor

unit. Electric shock can cause personal injury or death.

The minimum maintenance that should be performed on this

equipment is as follows.

1. Check outdoor coil for cleanliness each month during the

heating (heat pump only) or cooling season and clean as

necessary, but clean at least once each heating (heat pump

only) and cooling season.

2. Check fan motor and blade for cleanliness each heating and

cooling season and clean as necessary.

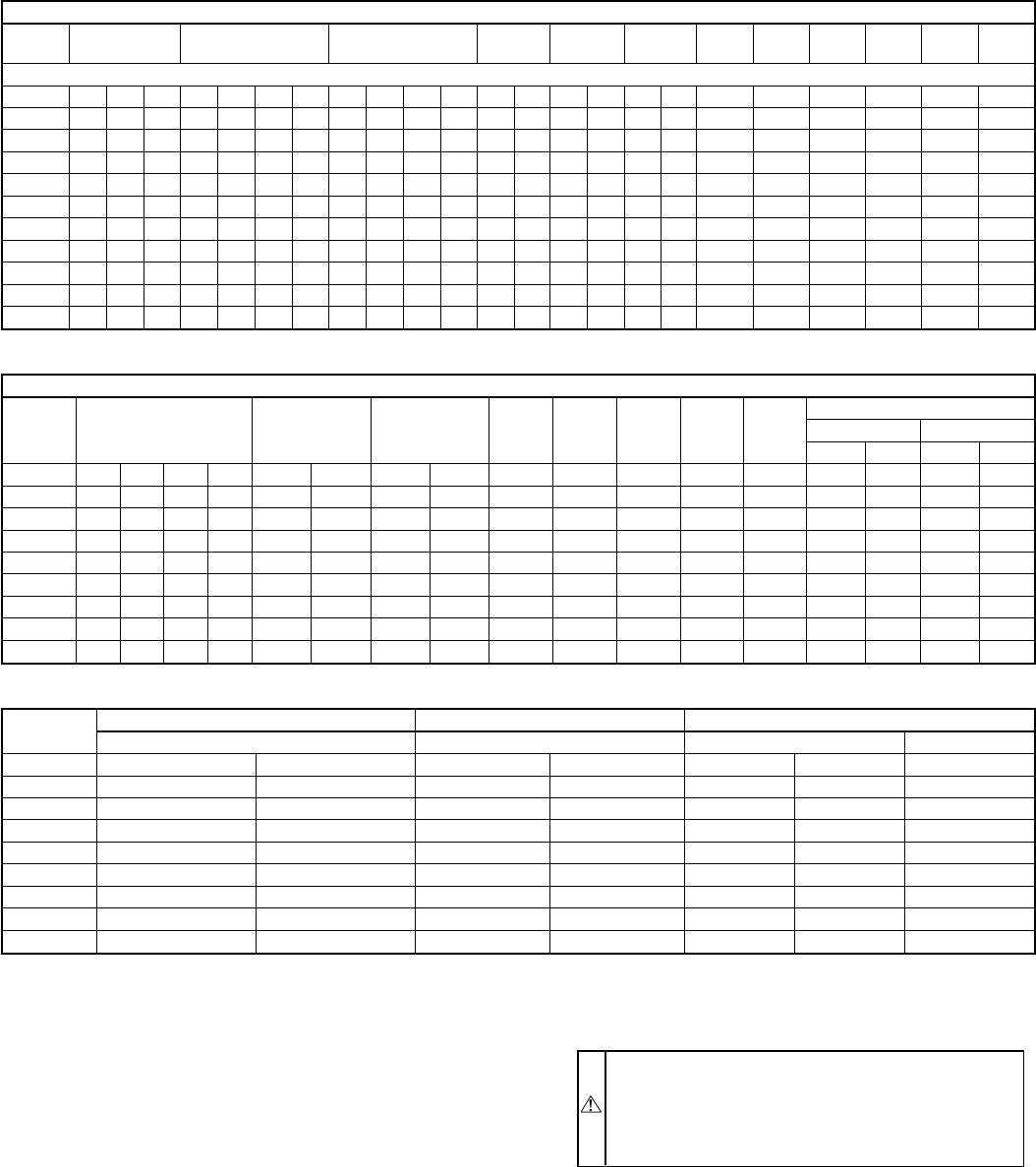

TABLE 23—SUBCOOLING AT LIQUID-SERVICE VALVE FOR UNITS PRODUCED THROUGH DECEMBER, 1992

RELIANT AIR CONDITIONERS

Model 590A 591A/592A 593A/594A 593B 593C 594C 595A 596A 597A 597B

598A

High

598A

Low

Series ABCABCDABCDABABABAAAAAA

014 14 14 — 14 14 14 — 66——————————————

018 17 17 — 14 14 14 — 77——11 — 99—— 98————

024 13 13 — 17 17 17 — 88——13 — 16 21 12 — 13 12 11 13 ——

030 15 15 — 91010— 6 6 10 13 11 — 15 15 14 — 10 9 10 11 ——

036 13 12 — 16 16 16 — 12 12 5 — 9 — 13 12 16 — 14 13 12 14 12 9

038 ———————————16 ———————————

042 13 13 14 16 19 19 15 12 12 ——11 — 13 — 21 — 11 11 15 15 ——

048 15 14 — 18 14 18 — 14 14 ——18 — 17 — 14 — 10 10 11 11 12 9

060 19 22 — 18 18 18 — 14 14 ——11 — 16 — 19 —— — 12 11 12 9

RELIANT HEAT PUMPS

Model 690A 691A/692A 693A/694A 693B 693C 694C 697A 697B

698A

Cooling Heating

High Low High Low

Series ABCDABABA A A A AAAAA

014 777—————— — — — —————

018 18 18 18 — 16 16 11 11 10 9 7 9 10 ————

024 18 18 18 — 16 16 11 11 13 6 5 11 11 ————

030 13 13 13 — 20 20 10 10 11 10 10 9 10 ————

036 18 18 18 — 14 14 10 10 11 13 12 9 10 12 7 18 15

042 13 11 11 — 18 18 15 15 12 10 12 11 12 ————

048 22 17 15 14 19 14 13 13 — 15 12 10 11 14 9 25 18

060 23 23 23 — 13 13 14 14 — 15 10 12 7 14 9 22 21

MODEL

CUBE UNIT—AIR CONDITIONERS CUBE UNIT—HEAT PUMPS HORIZONTAL AIR CONDITIONERS

561A/571A 661A/671A 566D 566E

Series ABABCDA

014 ————10 ——

018 15 16 11 14 12 — 17

024 14 11 14 8 —— 19

030 12 12 9 10 — 12 —

036 18 16 11 7 —— —

042 18 17 7 ————

048 — 17 12 ————

060 — 21 10 ———

—45—