connection will be exposed to moisture, it is very important to

cover the entire connection completely to prevent an electrochemi-

cal action that will cause the connection to fail very quickly. Do

not reduce the effective size of wire, such as cutting off strands so

that the wire will fit a connector. Proper size connectors should be

used. Check all factory and field electrical connections for

tightness. This should also be done after the unit has reached

operating temperatures, especially if aluminum conductors are

used.

II. CONTACTORS

NOTE: The section applies to single-speed models only.

The contactor provides a means of applying power to unit using

low voltage (24v) from transformer in order to power the contactor

coil. (See Fig. 11.) Depending on unit model, you may encounter

single-, double-, or triple-pole contactors to break power. One side

of the line may be electrically energized, so exercise extreme

caution when troubleshooting.

The contactor coil for residential air-conditioning units and heat

pumps is powered by 24vac. If contactor does not operate:

1. With power off, check whether contacts are free to move.

Check for severe burning or arcing on contact points.

2. With power off, use ohmmeter to check for continuity of

coil. Disconnect leads before checking. A low-resistance

reading is normal. Do not look for a specific value, as

different part numbers have different resistance values.

3. Reconnect leads and apply low-voltage power to contactor

coil. This may be done by leaving high-voltage power to

outdoor unit off, and turning thermostat to heat or cool.

Check voltage at coil with voltmeter. Reading should be

between 20v and 30v. Contactor should pull in if voltage is

correct and coil is good. If contactor does not pull in,

change contactor.

4. With high-voltage power off and contacts pulled in, check

for continuity across contacts with ohmmeter. A very low or

zero resistance should be read. Higher readings could

indicate burned or pitted contacts which may cause future

failures.

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ PAASFLDLKREW

SEFL JOSDJ

SEFL JOSDJ ATC

SEFL JOSDJ

SEFL JOSDJ UTUHD

SEFL JOSDJ

SEFL JOSDJC MD

SEFL JOSDJ

SEFL JOSDJHR ITYALK

SEFL JOSDJ

SEFL JOSDJ

A88412

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ PAASFLDLKREW

SEFL JOSDJ

SEFL JOSDJ ATC

SEFL JOSDJ

SEFL JOSDJ UTUHD

SEFL JOSDJ

SEFL JOSDJC MD

SEFL JOSDJ

SEFL JOSDJHR ITYALK

SEFL JOSDJ

SEFL JOSDJ

A88413

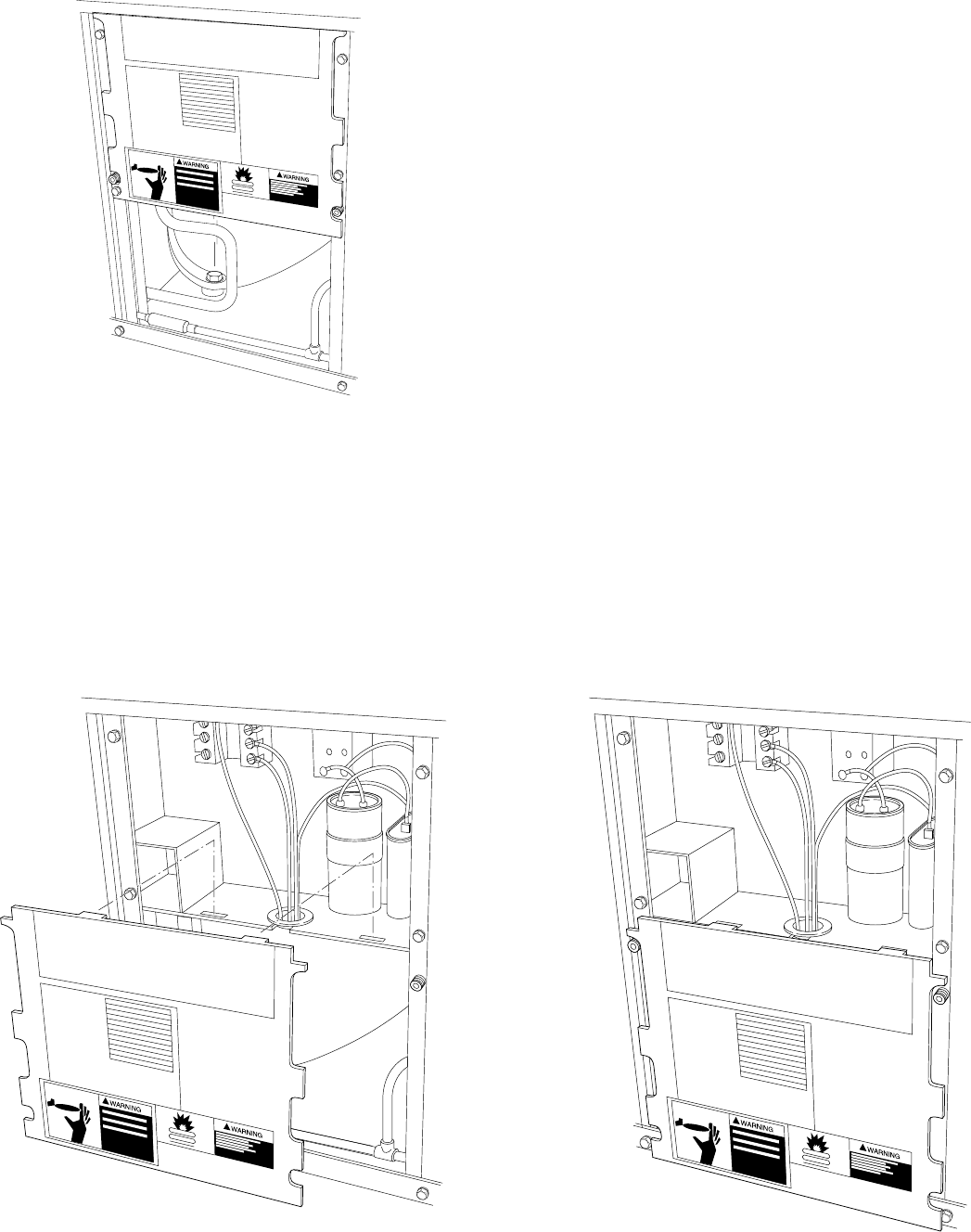

Fig. 10—Information Plate Removed/Installed Below Control Box

Fig. 9—Information Plate

A88411

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ

SEFL JOSDJ PAASFLDLKREW

SEFL JOSDJ

SEFL JOSDJ ATC

SEFL JOSDJ

SEFL JOSDJ UTUHD

SEFL JOSDJ

SEFL JOSDJC MD

SEFL JOSDJ

SEFL JOSDJHR ITYALK

SEFL JOSDJ

SEFL JOSDJ

—13—