35

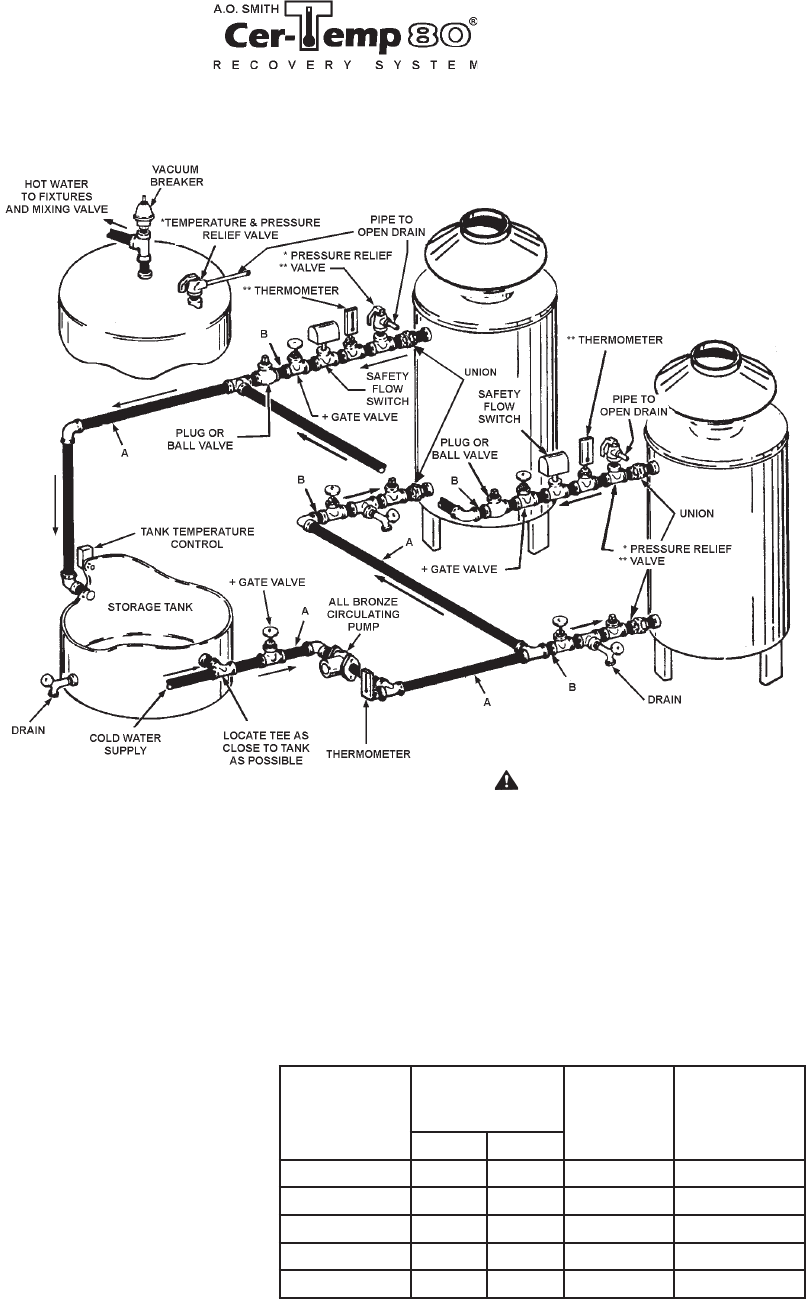

TWO HW-399's, HW-420's, HW-520's, HW-610's or HW-670's UP-FLOW MODEL

COMMERCIAL BOILER WITH VERTICAL TANK, CER-TEMP 80

IMPORTANT

THE INSTALLATION OF SAFETY FLOW SWITCH AS SHOWN IS

REQUIRED TO PROTECT THE BOILER IN CASE OF WATER SERVICE

INTERRUPTION OR CIRCULATOR FAILURE.

+ PIPING AND FITTINGS BETWEEN GATE VALVES AND BOILERS

SHOULD BE BRASS OR BRONZE. OTHER PIPING SHOULD

CONFORM TO LOCAL CODES.

GATE VALVES ARE SHOWN FOR SERVICING BOILER. HOWEVER,

LOCAL CODES SHALL GOVERN THEIR USAGE.

* PRESSURE RELIEF VALVE RATING SHOULD NOT EXCEED

PRESSURE CAPACITY OF ANY COMPONENT IN THE SYSTEM.

** INSTALL THERMOMETER AND PRESSURE RELIEF IN OPENINGS

PROVIDED ON HW-520, HW-610 & HW-670.

WIRING - FIGURES 21 to 27 on

pages 28 to 32.

HEATERS SPACED 30" APART

INSTALL IN ACCORDANCE

WITH ALL LOCAL CODES

FIGURE 30.

DANGER

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE USE TEMPERATURE

AT FIXTURES. SEE TANK TEMPERATURE CONTROL WARNING ON PAGE 11. IF

HIGHER PREHEAT TEMPERATURES ARE NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE FOR HOT WATER SUPPLIED

TO FIXTURES.

USE THIS TABLE FOR CORRECT

PUMP AND WATER PIPE SIZE

Model

Number

Minimum

Pipe Size

(Inches)

B & G

Pump

Size

*Armstrong

Pump Size

A B

HW-300 2" 1-1/2" 2" S-35

HW-399 2" 1-1/2" 2" S-35

HW-420 2" 1-1/2" 2" S-35

HW-520 2" 1-1/2" 2" S-35

HW-610/670 2-1/2" 1-1/2" 2-1/2" S-45 2-1/2"

* Assumes 50 equivalent feet of piping or less.