32

motor to reset and recognize new speed selection. Turn on

power to furnace. Verify selected CFM by counting the green

CFM LED blinks.

In general lower heating speeds will: reduce electrical consump-

tion, lower operating sound levels of the blower, and increase the

outlet air temperature delivered to the home. The speeds avail-

able allow the blower performance to be optimized for the particu-

lar homeowner’s needs.

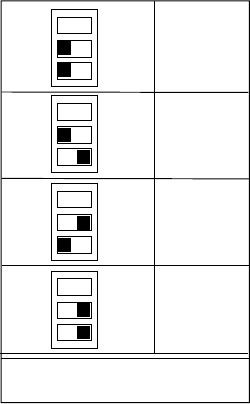

BLOWER HEAT OFF DELAY TIMINGS

The integrated control module provides a selectable heat off delay

function. The heat off delay period may be set to 90, 120, 150, 180

seconds using the DIP switches or jumper provided on the control

module. The delay is factory shipped at 150 seconds but may be

changed to suit the installation requirements and/or homeowner

preference. Refer to the following figures for switch positions and

corresponding delay times.

Heat Off

Delay

90 Seconds

ON

ON 1

2

3

Heat Off

Delay

120 Seconds

Heat Off

Delay

150 Seconds

Heat Off

Delay

180 Seconds

ON

OFF

1

2

3

ON 1

2

3

1

2

3

OFF

OFF

Heat Off Delay

(* indicates factory setting)

*

OFF

Heat Off Delay Switches

XVXV

XVXV

XV

. NO. NO

. NO. NO

. NO

RMRM

RMRM

RM

AL SEQUENAL SEQUEN

AL SEQUENAL SEQUEN

AL SEQUEN

CE OCE O

CE OCE O

CE O

F OPERAF OPERA

F OPERAF OPERA

F OPERA

TITI

TITI

TI

OO

OO

O

NN

NN

N

POWER UP

The normal power up sequence is as follows:

• 115 VAC power applied to furnace.

• Integrated control module performs internal checks.

• Integrated control module flashes LED one time.

• Integrated control module monitors safety circuits

continuously.

• Furnace awaits call from thermostat.

HEATING MODE

The normal operational sequence in heating mode is as follows:

• R and W1 (or R and W1/W2) thermostat contacts close,

initiating a call for heat.

• Integrated control module performs safety circuit checks.

• Induced draft blower is energized on high speed for a 10-

second prepurge. Humidifier terminals are energized with

induced draft blower.

• Induced draft blower steps to low speed following prepurge.

Low stage pressure switch contacts are closed.

• Igniter warm up begins upon step to low speed and

presence of closed low stage pressure switch contacts.

• Gas valve opens at end of igniter warm up period, delivering

gas to burners and establishing flame.

• Integrated control module monitors flame presence. Gas

valve will remain open only if flame is detected.

• If the thermostat call is for low heat, gas valve and induced

draft blower will continue on low stage. If the call is for high

heat, the gas valve and induced draft blower will change to

high stage.

• Circulator blower is energized on heat speed following a

fixed thirty second blower on delay. The circulator blower

requires thirty (30) seconds to ramp up to full speed.

Electronic air cleaner terminals are energized with circulator

blower.

• Furnace is now operating on the specified stage called for

by the two-stage thermostat.

• Furnace runs, integrated control module monitors safety

circuits continuously.

• If the two-stage thermostat changes the call from low heat

to high heat, the integrated control module will immediately

switch the induced draft blower, gas valve, and circulator

blower to their high stage settings.

• If the two-stage thermostat changes the call from high heat

to low heat, the control will immediately switch the induced

draft blower and gas valve to their low stage settings. The

circulator blower will remain on high heating speed for thirty

(30) seconds before switching to the low heat circulating

speed.

• R and W1 (or R and W1/W2) thermostat contacts open,

completing the call for heat.

• Gas valve closes, extinguishing flame.

• Induced draft blower is de-energized following a fifteen

second post purge. Humidifier terminals are de-energized.

• Circulator blower continues running for the selected heat

off delay period (90, 120, 150 or 180 seconds). The speed

run during this period depends on the last heat call provided

by the thermostat.

If the last call for heat was a call for low heat, the air circulator

motor will run on low heat speed for the duration of the heat

off delay period (90, 120, 150 or 180 seconds).

If the last call for heat was a call for high heat, the air

circulating motor will run on the high heating speed for thirty

(30) seconds and then switch to the low heating speed for

the balance of the heat off delay period (60, 90, 120 or 150

seconds).

• Circulator blower and electronic air cleaner terminals are

de-energized.

• Circulator blower ramps down to OFF during the 30 seconds

following the heat off delay period.

• Furnace awaits next call from thermostat.

COOLING MODE

The normal operational sequence in cooling mode is as follows:

• R and YLO/G or Y/G thermostat contacts close, initiating a

call for cool.

• Integrated control module performs safety circuit checks.

• Outdoor fan and compressor are energized to their

appropriate speed.