18

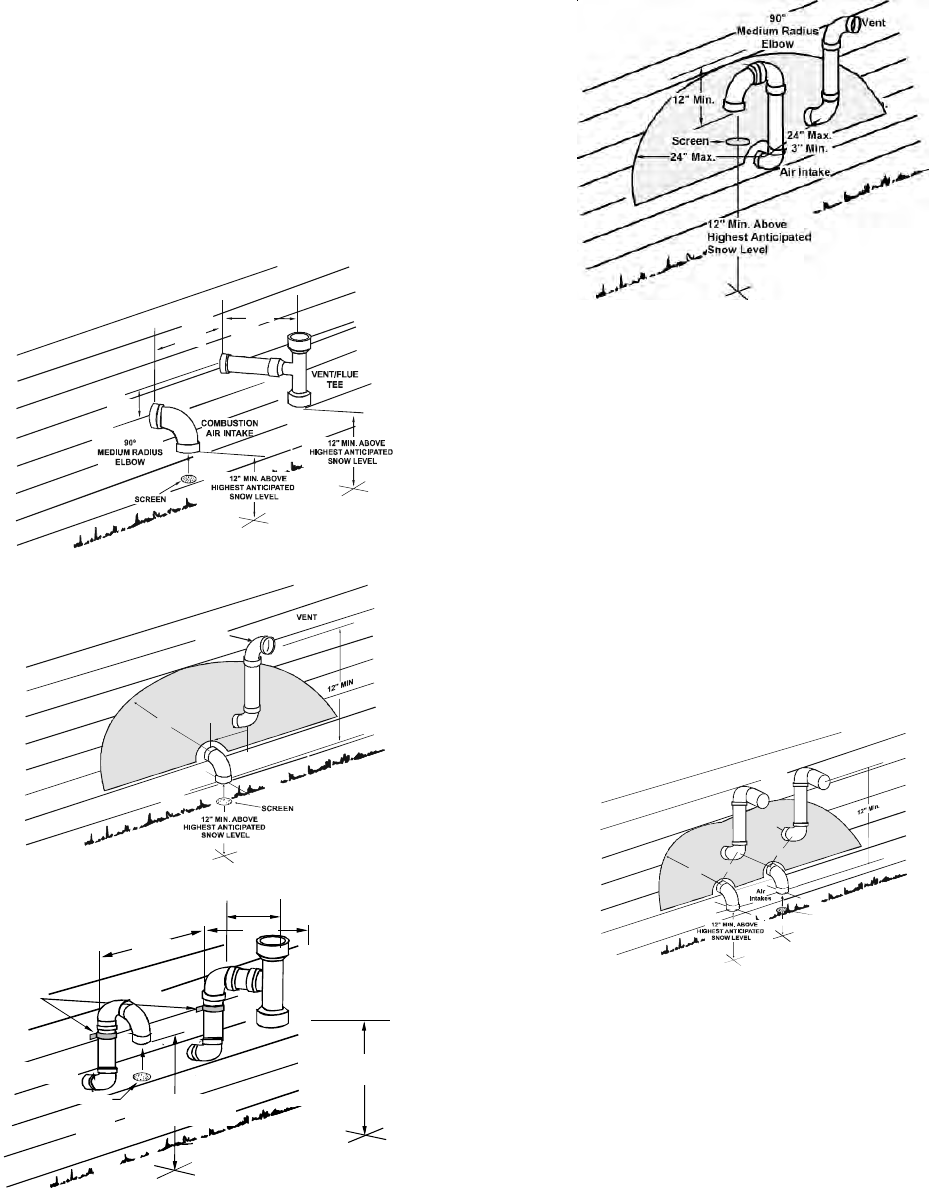

Horizontal terminations should be as shown in the following fig-

ure. Refer to Section IX, Vent/Flue Pipe and Combustion Pipe -

Termination Location for location restrictions. A 2 3/8 inch diameter

wall penetration is required for 2” diameter pipe while a 3 1/2 inch

diameter hole is required for 3” diameter pipe. To secure the pipe

passing through the wall and prohibit damage to piping connec-

tions, a coupling should be installed on either side of the wall and

solvent cemented to a pipe connecting the two couplings. The

pipe length should be the wall thickness plus the depth of the

socket fittings to be installed on the inside and outside of the wall.

The wall penetration should be sealed with silicone caulking ma-

terial.

12" MIN

3" MIN

24" MAX

3" MIN

24" MAX

Standard Horizontal Terminations (Dual Pipe)

24" MAX

3" MIN

24" MAX

AIR

INTAKE

90°

MEDIUM

RADIUS

ELBOW

Alternate Horizontal Vent Termination (Dual Pipe)

SUPPORT

STRAPS

90°

MEDIUM

RADIUS

ELBOWS

12" MIN.

VENT/FLUE

TEE

SCREEN

COMBUSTION

AIR INTAKE.

12" MIN. ABOVE

HIGHEST ANTICIPATED

SNOW LEVEL

12" MIN. ABOVE

HIGHEST ANTICIPATED

SNOW LEVEL

3" MIN.

24" MAX.

12" MIN

Standard Horizontal Terminations Above Anticipated Snow

Level (Dual Pipe)

Alternate Vent Termination Above Anticipated Snow Level

(Dual Pipe)

In a basement installation, the pipes may be run between the joist

spaces. If the pipes must go below the joist and then up into the

last joist space to penetrate the header, two 45° elbows should be

used to reach the header rather than two 90° elbows.

VENT/INTAKE T ERMINATIONS F OR I NSTALLATION OF MULTIPLE

DIRECT V ENT F URNACES

If more than one direct vent furnace is to be installed vertically

through a common roof top, maintain the same minimum clear-

ances between the exhaust vent and air intake terminations of

adjacent units as with the exhaust vent and air intake terminations

of a single unit.

If more than one direct vent furnace is to be installed horizontally

through a common side wall, maintain the clearances as in the

following figure. Always terminate all exhaust vent outlets at the

same elevation and always terminate all air intakes at the same

elevation.

V

ents

24" Max.

3" Min.

12" Min.

Screen

24" Max.

90°

Medium

Radius

Elbows

24" Max.

3" Min.

3" Min.

Horizontal Venting Of Multiple Units

CONCENTRIC V ENT T ERMINATION

Refer to the directions provided with the Concentric Vent Kit (DCVK)

for installation specifications.

X. COX. CO

X. COX. CO

X. CO

NDND

NDND

ND

ENSAENSA

ENSAENSA

ENSA

TE DRAIN LINES & DRAIN TRAPTE DRAIN LINES & DRAIN TRAP

TE DRAIN LINES & DRAIN TRAPTE DRAIN LINES & DRAIN TRAP

TE DRAIN LINES & DRAIN TRAP

GENERAL

A condensing gas furnace achieves its high level of efficiency by

extracting almost all of the heat from the products of combustion

and cooling them to the point where condensation takes place.

The condensate which is generated must be piped to an appropri-

ate drain location.

In upright installations, the furnace’s drain hoses may exit either

the right or left side of the furnace. NOTE: If the alternate vent/flue

outlet is utilized in an upright installation, the drain trap and drain

connections must be located on the same side as the alternate

vent/flue outlet.

In horizontal installations, the drain hoses will exit through the

bottom (down side) of the unit with the drain trap suspended be-

neath the furnace. The field-supplied drain system must be in