14

STANDARD F URNACE C ONNECTIONS

It is the responsibility of the installer to ensure that the piping

connections to the furnace are secure, airtight, and adequately

supported.

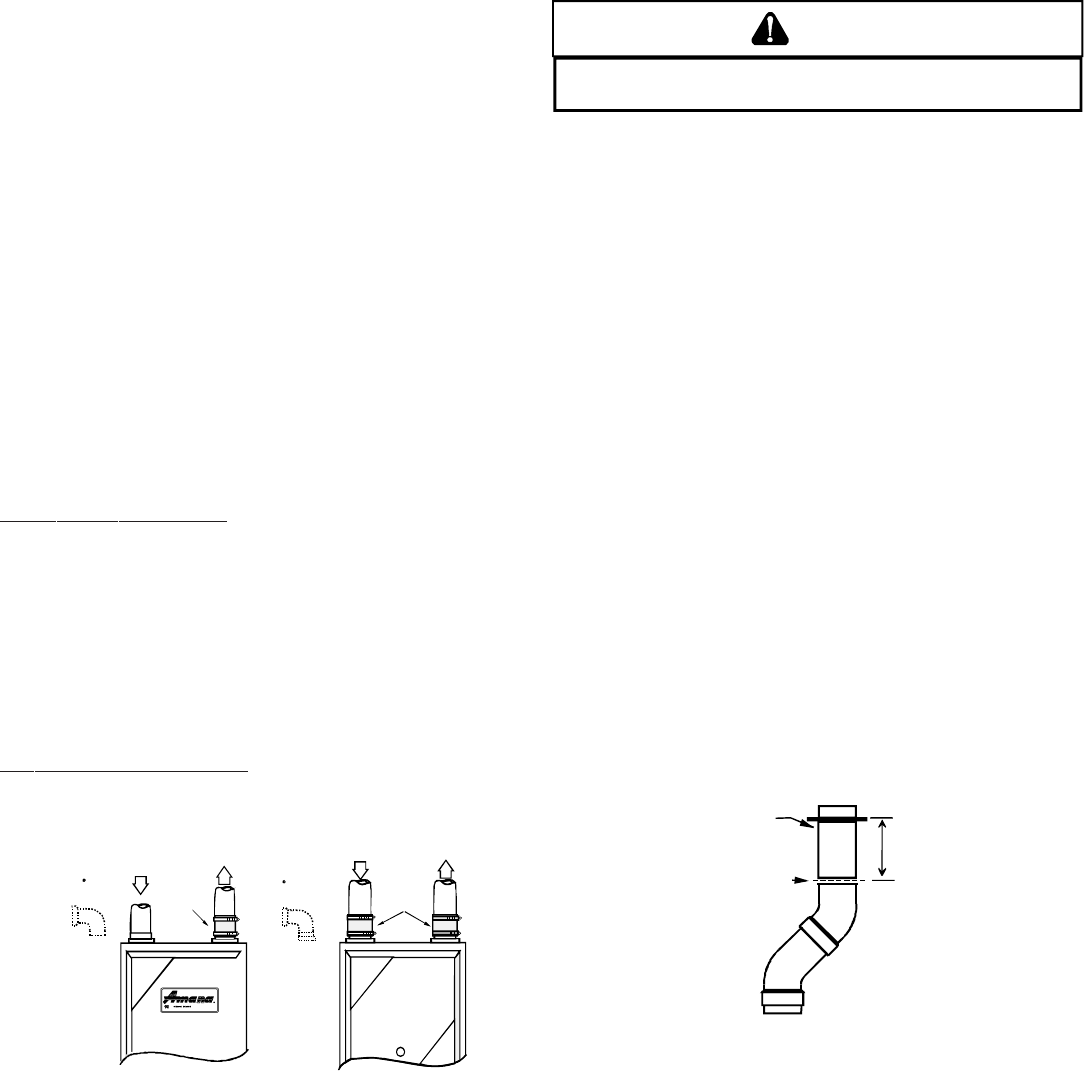

As shipped, attachment “couplings” for vent/flue and combustion

air intake pipe connections are provided on the furnace’s top cover

(upflow) or basepan (counterflow). To use the standard connec-

tions, field supplied vent/flue pipe and combustion air intake pipe

(when applicable) should be secured directly to the furnace at

these locations.

VENT/FLUE PIPE

Vent/flue pipe can be secured to the vent/flue coupling using the

rubber coupling and worm gear hose clamps provided with this

furnace (see “Standard Connections” figure). The rubber coupling

allows separation of the vent/flue pipe from the furnace during

servicing. NOTE: Do not use other commercially available “no hub

connectors” due to possible material conflicts. The vent/flue pipe

can also be secured using a PVC or ABS elbow or coupling using

the appropriate glue (see Section IX, Materials and Joining Meth-

ods.

NOTE: For non-direct vent installations, a minimum of one 90°

elbow should be installed on the combustion air intake coupling

to guard against inadvertent blockage.

COMBUSTION AIR PIPE

DIRECT VENT INSTALLATIONS

On upflow units secure the combustion air intake pipe directly to

the air intake coupling. On counterflow units secure the combus-

tion air intake pipe to the air intake coupling using the rubber cou-

pling and worm gear hose clamps provided with the unit. The

counterflow rubber coupling allows service removal of air intake

piping internal to the furnace blower compartment. NOTE: Be-

cause of probable material conflicts, do not use other commer-

cially available “no hub connectors”. The combustion air intake

pipe can also be secured directly to the counterflow unit air intake

pipe coupling.

NON-DIRECT V ENT I NSTALLATIONS

A minimum of one 90° elbow should be installed on the combus-

tion air intake “coupling” to guard against inadvertent blockage.

RUBBER

CO UPLING

WITH WORM

GEAR CLAMPS

RUBBER

COUPLINGS

WITH WORM

GEAR CLAMPS

COMBUSTION

AIR PIPE

(DIRECT VENT ONLY)

COMBUSTION

AIR PIPE

(DIRECT VENT ONLY)

VENT/FLUE

PIPE

VENT/FLUE

PIPE

90 PVC

ELBOW

(NON-DIRECT VENT)

90 PVC

ELBOW

(NON-DIRECT VENT)

STANDARD CONNECTIONS

OR

OR

UPFLOW COUNTERFLOW

Standard Connections

ALTERNATE F URNACE C ONNECTIONS

If the standard locations are undesirable for a specific installation,

alternate side panel locations are available for both combustion

air inlet and vent/flue pipe connections. These locations may be of

particular benefit to upright upflow installations requiring additional

access to an A coil, or to upright counterflow installations requiring

additional access to a filter or electronic air cleaner, or to horizontal

installations desiring vent/flue (and combustion air intake) piping

run vertically from the side of the cabinet.

NOTE: Standard and alternate locations can be combined (i.e., an

installation may use the standard combustion air intake location

but use the alternate vent/flue location or vice versa), if needed.

WARNING

E

DGES OF SHEET METAL HOLES MAY BE SHARP.

U

SE GLOVES AS A PRE-

CAUTION WHEN REMOVING HOLE PLUGS.

ALTERNATE VENT/FLUE LOCATION

The alternate vent/flue location is the large hole directly in line with

the induced draft blower outlet. To use the alternate vent/flue loca-

tion refer to the following steps, the “Vent/Flue Pipe Cuts” figure,

and the “Alternate Vent/Flue Location” figure.

NOTE: Counterflow instructions follow the upflow instructions.

1. Remove and save the four screws securing the vent/flue

coupling to the furnace top panel.

Counterflow units.

Remove and save the four screws securing the vent/flue

coupling to the furnace basepan. Also remove the three

screws securing the furnace’s internal vent/flue piping to

the blower deck.

2. Upflow and Counterflow units.

Loosen the worm gear hose clamps on the rubber elbow

and detach it from both the induced draft blower and the

vent/flue pipe.

3. Upflow and Counterflow units.

Remove the vent/flue pipe from the furnace.

4. Cut the vent/flue pipe 3.75 inches from the flanged end of

the pipe. See Vent/Flue Pipe Cuts figure. The section of

pipe attached to the coupling will reach through the side

panel to the induced draft blower. Discard remaining pipe

and elbows.

Counterflow units.

Cut the vent/flue pipe 3.75 inches from the blower deck

coupling. See Vent/Flue Pipe Cuts figure. Save vent/flue

pipe attached to blower deck coupling for use in the alternate

location. Discard remaining pipe and elbows.

FLANGE

CUT

HERE

3.75"

Vent/Flue Pipe Cuts

5. Remove plastic plug from alternate vent/flue location.

Relocate and install plug in standard vent/flue location (top

cover).

Counterflow units.

Remove plastic plug from alternate vent/flue location.

Relocate and install plug in standard vent/flue location

(basepan). Plug remaining hole in blower deck with plastic

plug included in the drain kit bag.

6. Upflow and Counterflow units.

Insert cut section of vent/flue pipe and coupling into alternate

vent/flue location. Using a rubber coupling and worm gear

hose clamps from the drain kit bag, attach the vent/flue

pipe and coupling to the induced draft blower. Secure the